Lifetime Prediction Method for 3D Printing Components

A technology for life prediction and printing components, applied in the field of additive manufacturing, which can solve the problems such as the inability to apply additive manufacturing, and achieve the effect of easy implementation, ensuring quality and safety, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described below with reference to the accompanying drawings.

[0019] The life prediction method of the present invention is suitable for nickel-based superalloy material components manufactured by additive manufacturing technology. Among them, the additive manufacturing technology mentioned in this article is the 3D printing technology, including but not limited to the Selected Laser Melting (Selected Laser Melting, SLM) process or the binder jetting technology and the like.

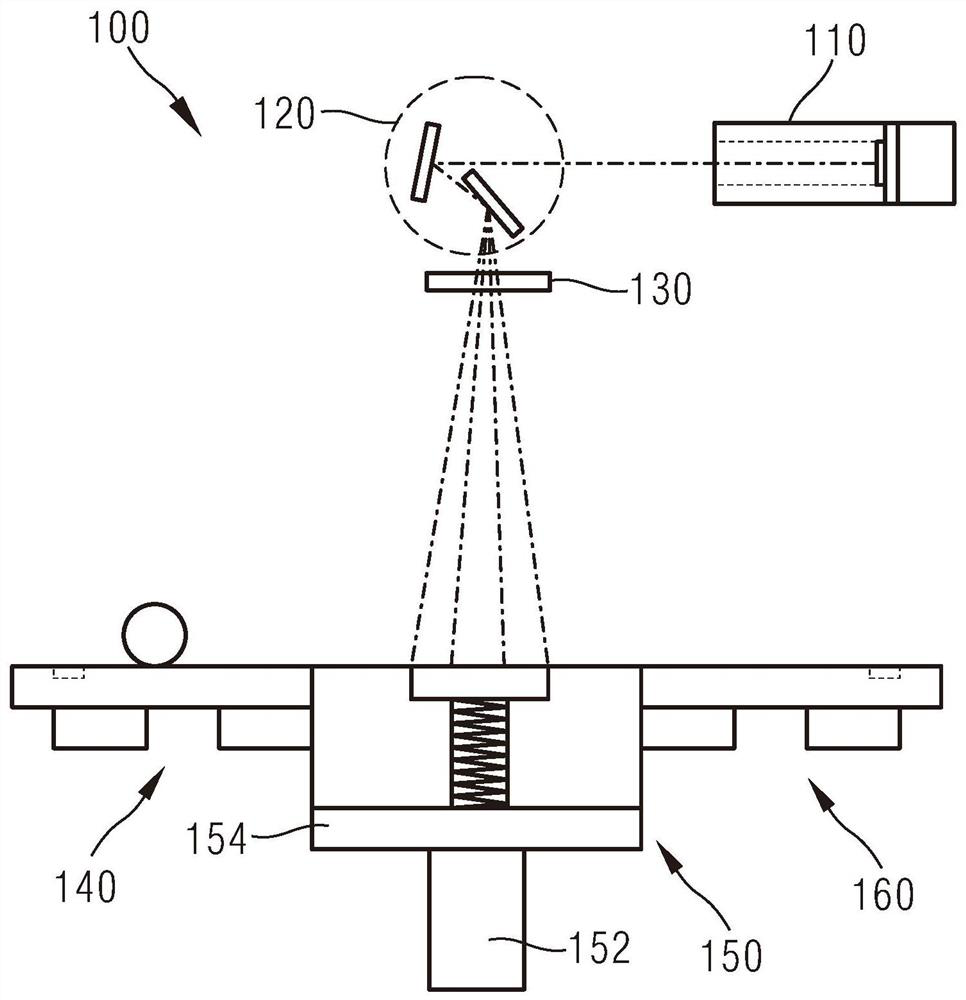

[0020] in, figure 1 is a schematic diagram of a selective laser melting device. like figure 1 As shown, the selective laser melting apparatus 100 includes a laser source 110 , a mirror scanner 120 , a prism 130 , a powder feeding tank 140 , a forming tank 150 and a recovery tank 160 . The laser source 110 is disposed above the selective laser melting device 100 to serve as a heating source for the metal powder, that is, to melt the meta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com