Device and method for detecting ultra-low residual reflectivity at boundary surface of large-size sheet laser neodymium glass package

A flake laser and detection device technology, applied in the measurement of scattering characteristics, etc., can solve problems such as large test errors, and achieve the effects of improving test accuracy, improving measurement reliability, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below with reference to the accompanying drawings and implementation, but the protection scope of the present invention should not be limited by this.

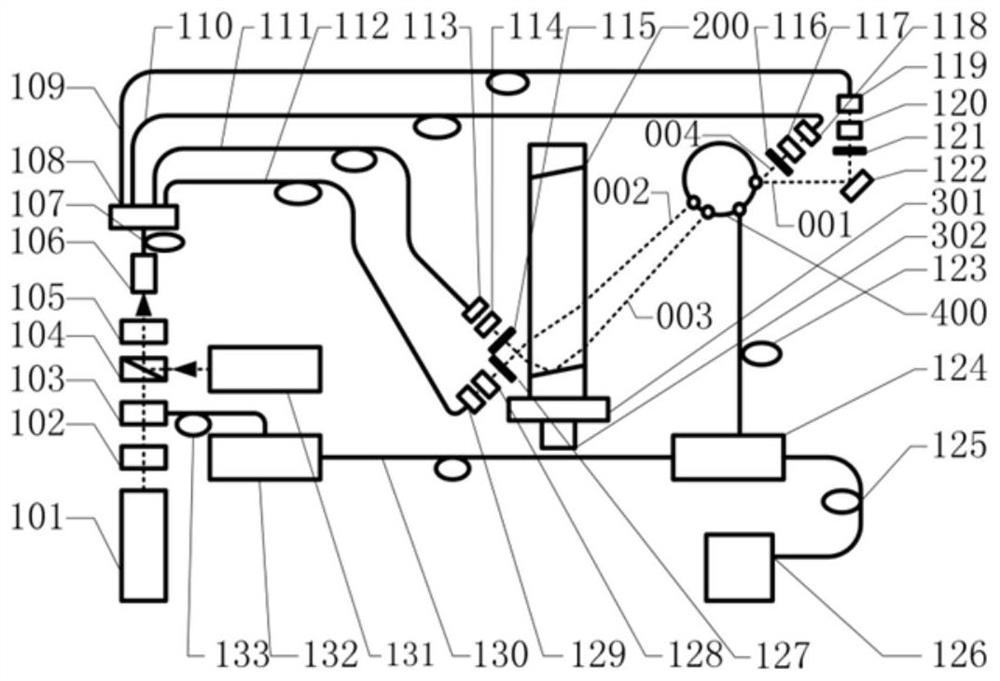

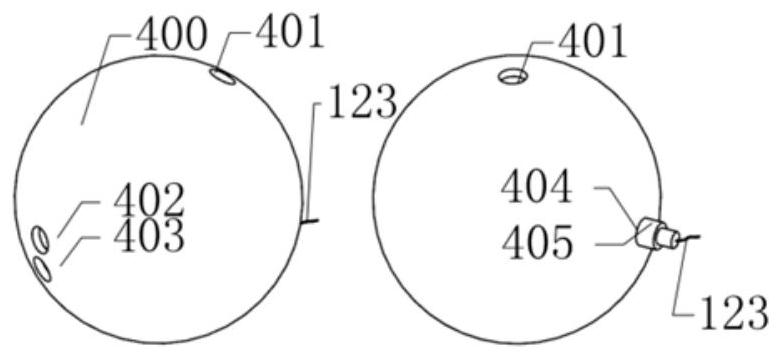

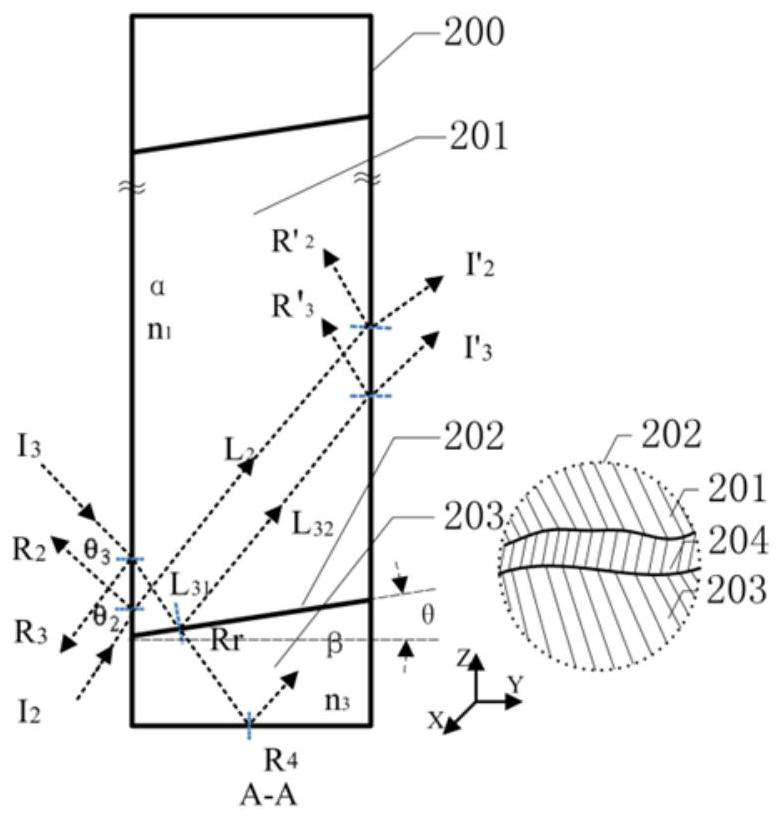

[0051] see first figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Image 6 , figure 1 It is a schematic diagram of the ultra-low residual reflection detection device for the large-size flake laser neodymium glass cladding interface of the present invention, figure 2 It is a schematic diagram of the structure of the integrating sphere used in the present invention. image 3 It is a schematic diagram of the optical path of the structure of the tested sample and the light at the cladding interface of the present invention. Figure 4 is a schematic diagram of the overall structure of the tested sample in the present invention, Figure 5 is the reflection schematic diagram and optical path of the standard sample used for system calibration in the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com