Mining area hydrofracture crack microseism monitoring application method

A technology of hydraulic fracturing and application method, applied in seismology, geophysical measurement, seismic signal processing, etc., can solve problems such as inability to accurately describe the length, width and reference height of fracture contour, inconvenient analysis of overall fracturing effect, etc. , to achieve the effect of optimizing the fracturing plan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

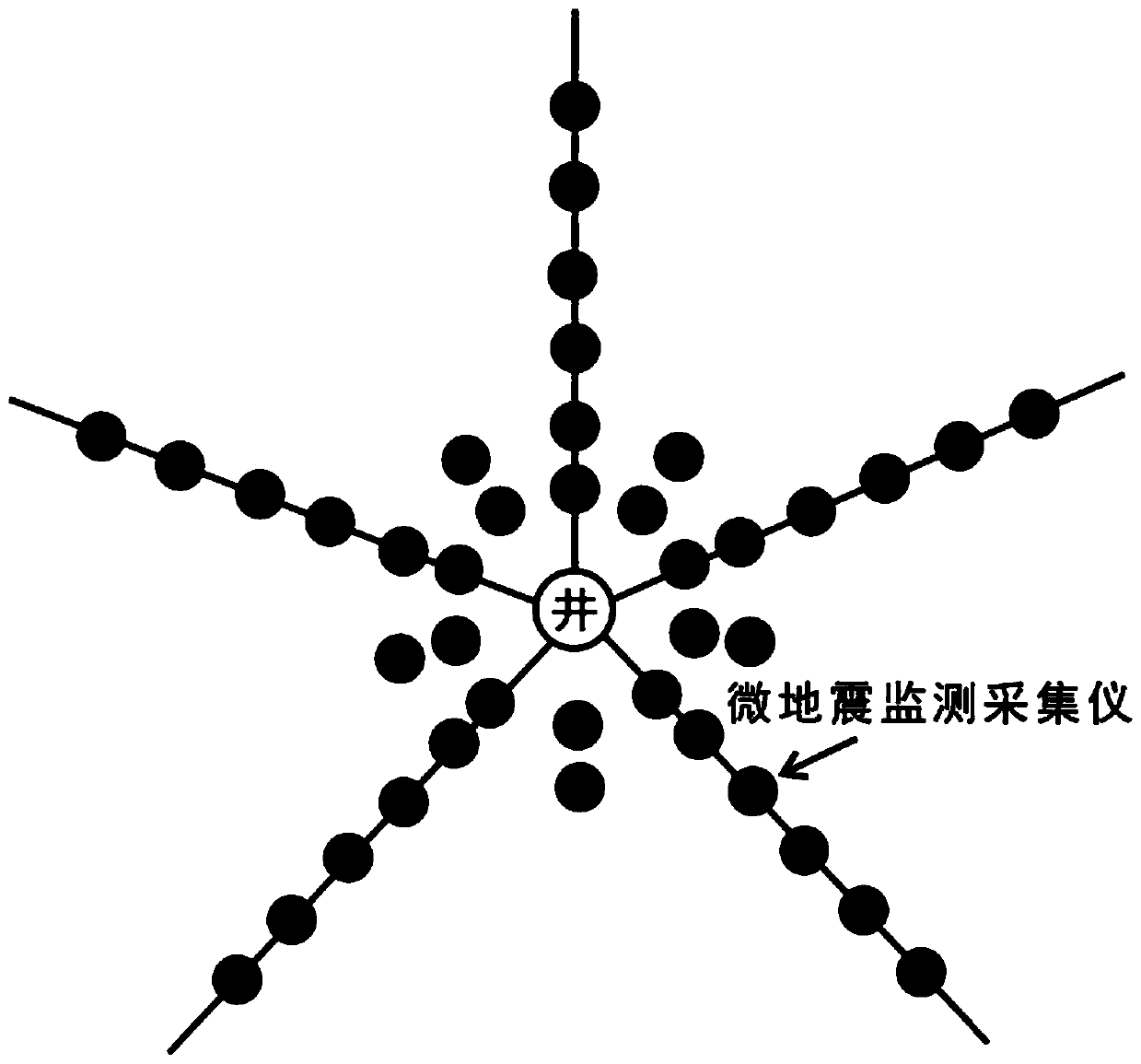

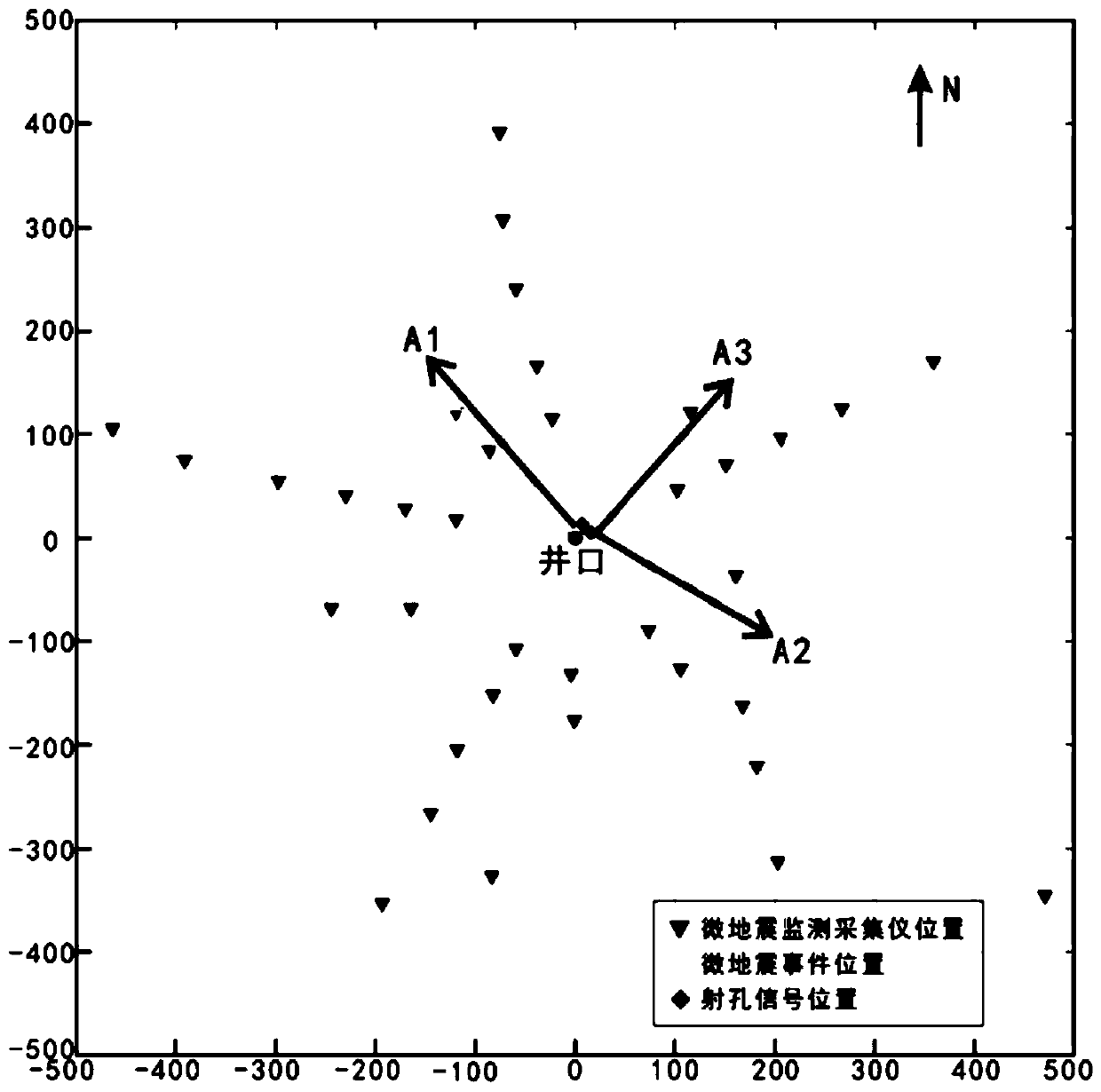

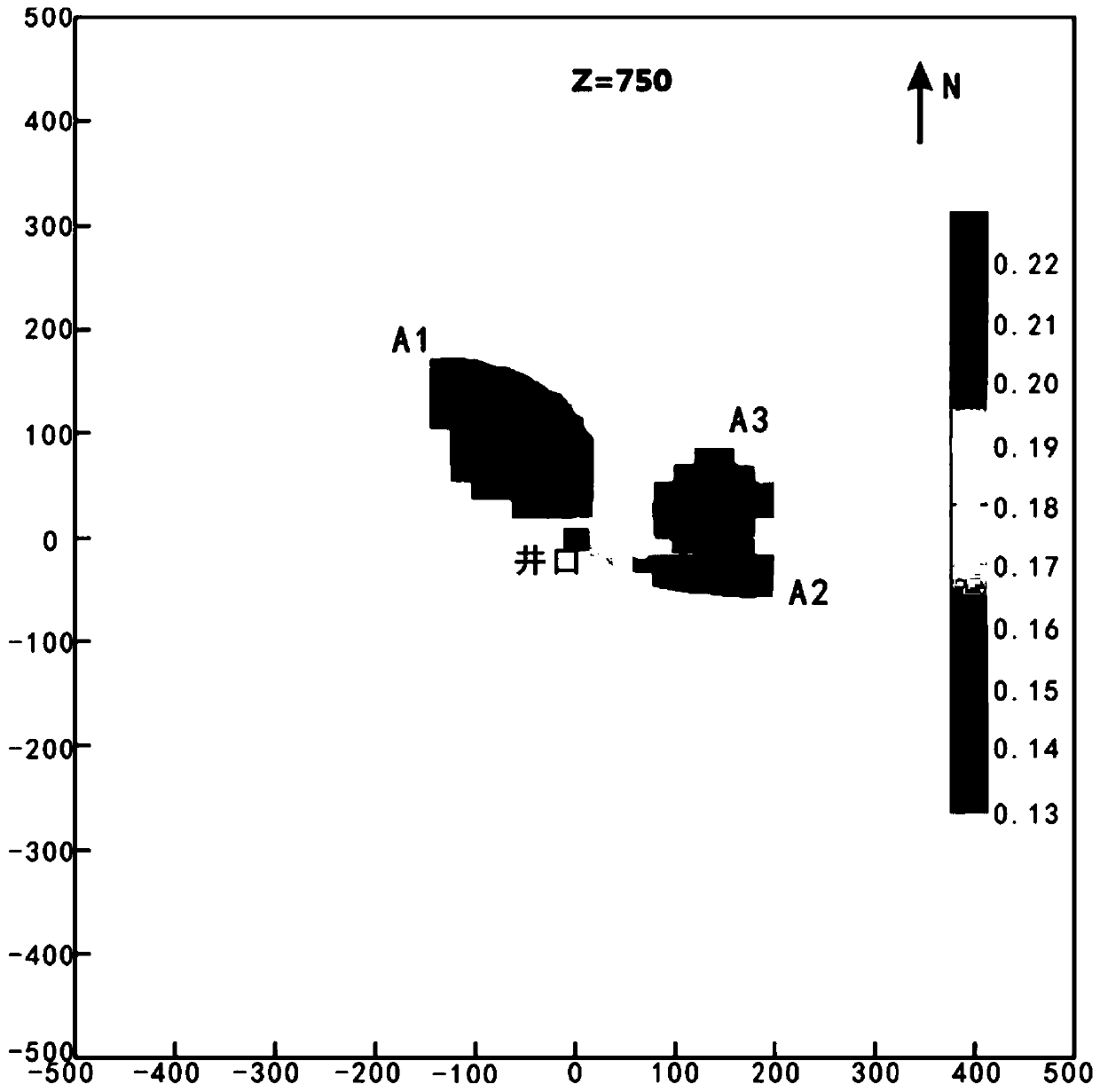

[0020] Refer to the attached Figure 1-5 Describe the application method of microseismic monitoring of hydraulic fracturing fractures in mining areas according to an embodiment of the present invention, including the following steps: S1: arranging monitoring equipment; figure 1 As shown, the monitoring equipment is a three-component microseismic monitoring and acquisition instrument. The equipment layout adopts the wellhead as the center, and the five-star layout and the two-ring layout are combined to arrange the monitoring stations. The five-star layout is to set the monitoring equipment at the wellhead. And along the five lines radially radiating outward from the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com