Driving vibration wind driven generator

A wind power generator and vibration-induced technology, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problem of limited battery life, difficult cables, inconvenient use, etc. problems, to achieve the effect of strong power generation capacity, controllable deformation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

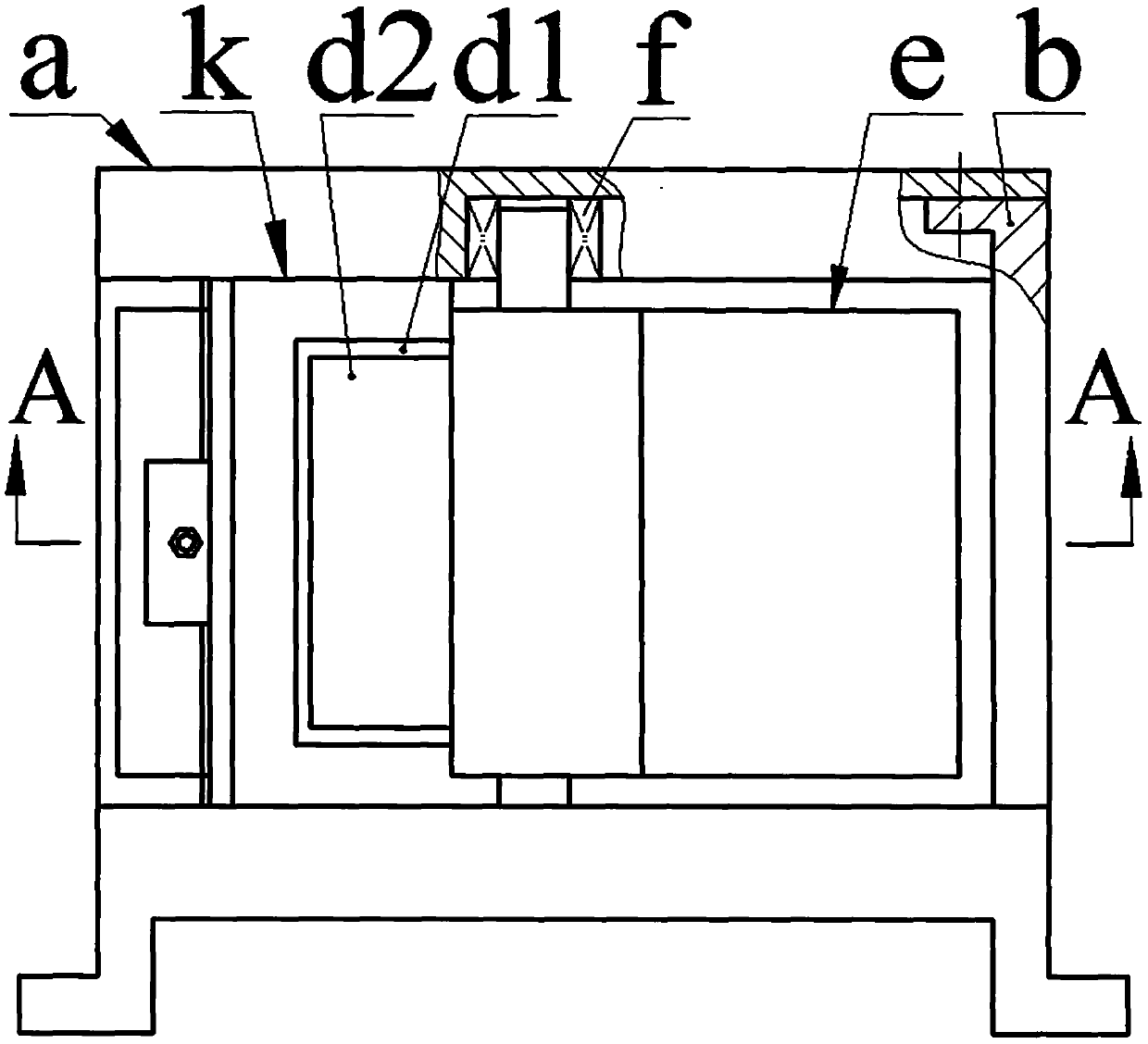

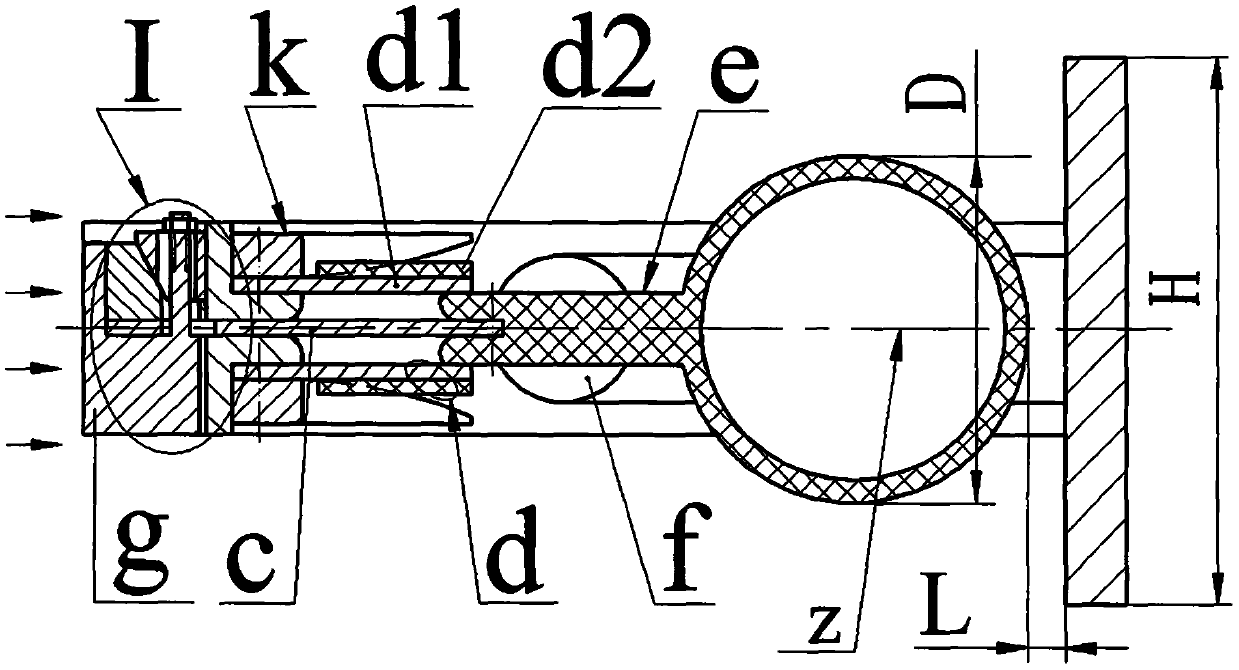

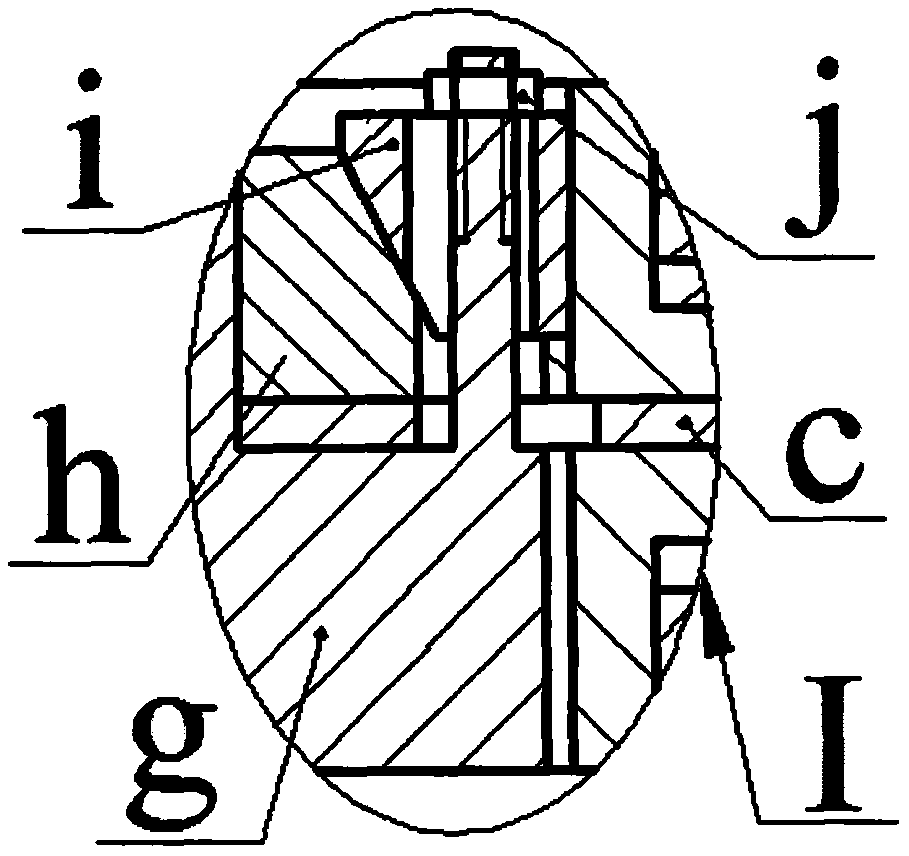

[0018] The bracket a is provided with an upper beam a1, a lower beam a2 and two cross beams a3 connecting the upper beam a1 and the lower beam a2, the inner walls of the upper beam a1 and the lower beam a2 are provided with a slideway a5, and the two cross beams a3 are placed One end of the upper beam a1 and the lower beam a2 with a gap a4 left between them, the other end of the upper beam a1 and the lower beam a2 is installed with a baffle b via screws; the seat plate g with stud g1 is provided with screws and fixed wedges h is installed with a reed c, which passes through the gap a4 between the two beams a3, the other end of the reed c is connected with the ear plate e1 of the blunt body e through screws, and the two ends of the ear plate e1 are equipped with The half-shaft e2 with the bearing f installed, the bearing f is installed in the slideway a5 of the upper beam a1 and the lower beam a2, the blunt body e is a hollow cylindrical shell, and the blunt body e is installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com