Method for suppressing super-amplitude of mechanical vibration table

A vibrating table, mechanical technology, applied in the field of fatigue test, can solve problems such as increased maintenance cost, low reliability, complex control system, etc., to reduce production and maintenance costs, improve stability and reliability, and simple control method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

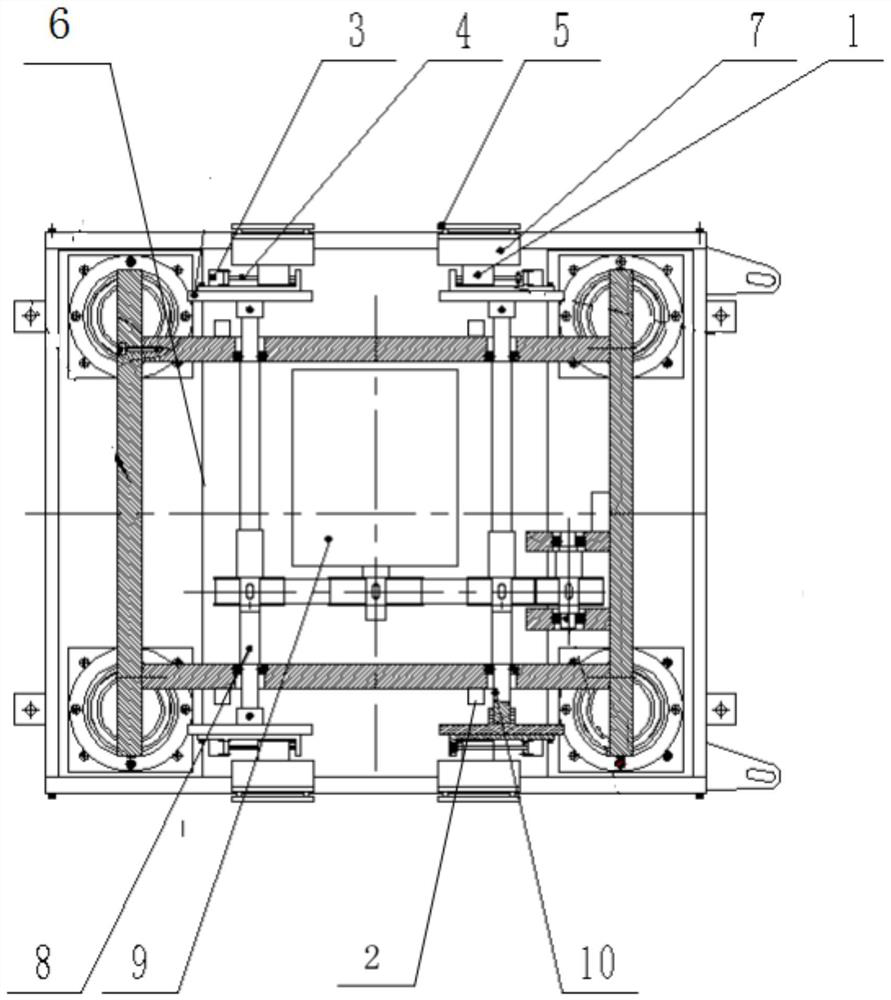

[0036] The mechanical vibrating table involved in this article includes a power assembly, a transmission assembly and four sets of wireless eccentric adjustment mechanisms arranged under the vibrating table table 6, the power assembly provides power for the transmission assembly, and the transmission assembly drives the four sets of wireless eccentric adjustment mechanisms to rotate synchronously; Four sets of wireless eccentric adjustment mechanisms are respectively installed at both ends of the first rotating shaft 8 and at both ends of the second rotating shaft 10;

[0037] Each group of eccentric adjustment mechanisms includes a stepping motor 3, a lead screw 4, a power module, a wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com