pressure measurement system

A measuring system and pressure technology, applied in measuring devices, measuring fluid pressure, vacuum gauges that measure medium pressure by measuring changes in thermal conductivity of medium, etc. , prone to human errors and other problems, to achieve the effect of fault judgment and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

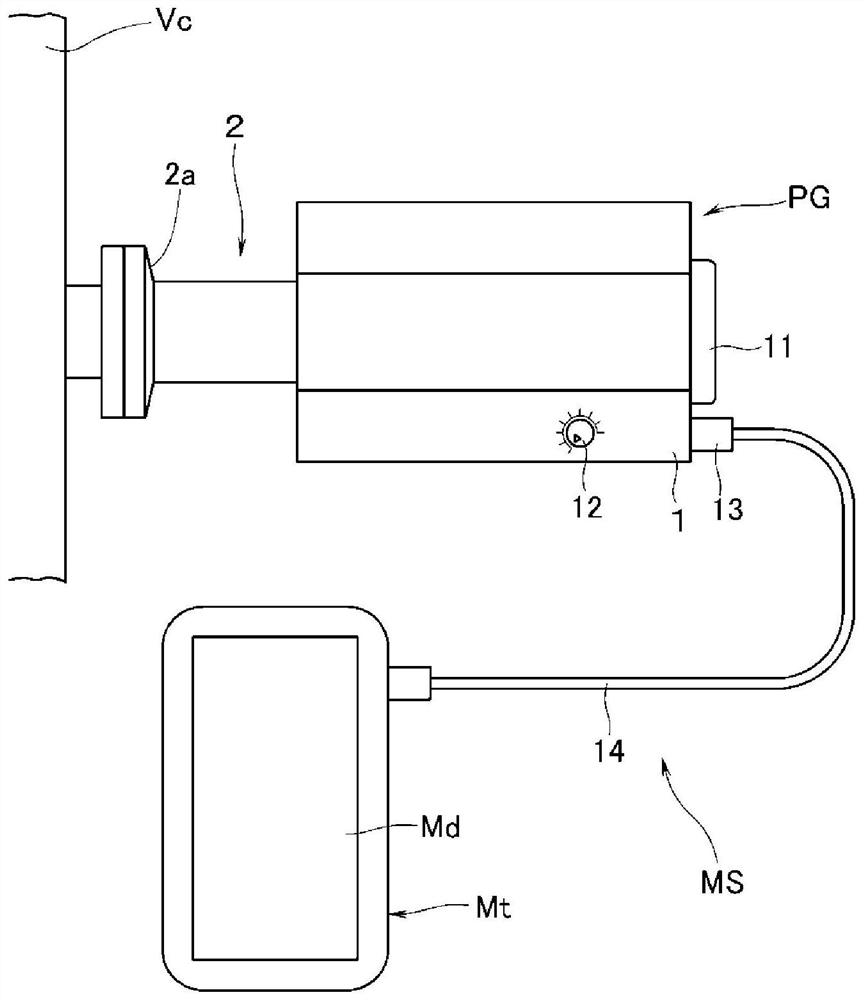

[0018] Referring to the drawings, in order to set the object to be measured Vc vacuum chamber vacuum processing apparatus, the vacuum gauge installation in the vacuum chamber is set to Vc Pirani vacuum gauge PG example, a pressure measurement of the present invention MS system embodiments.

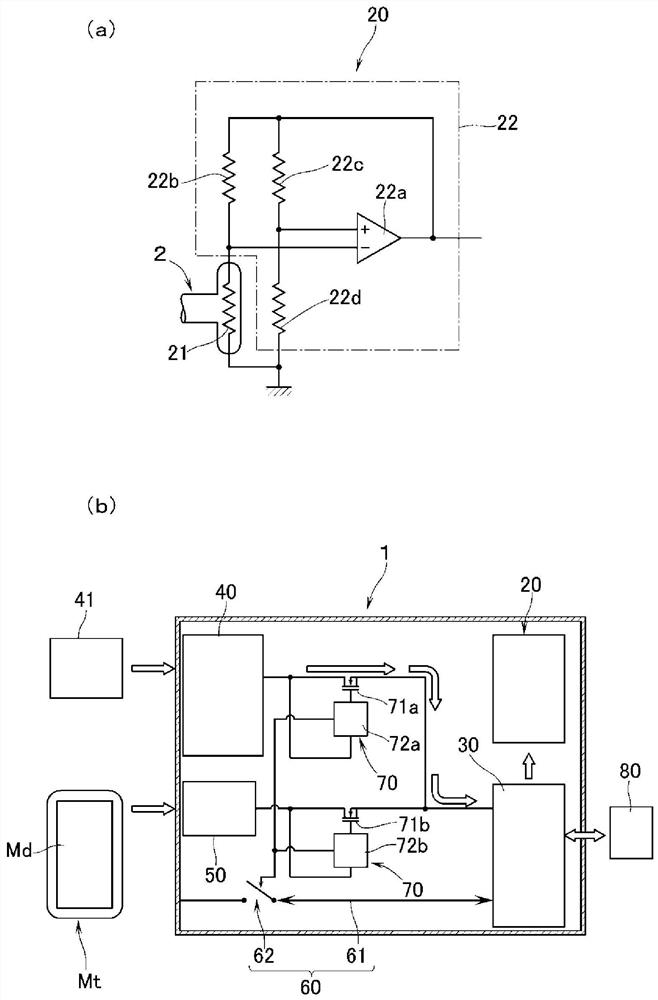

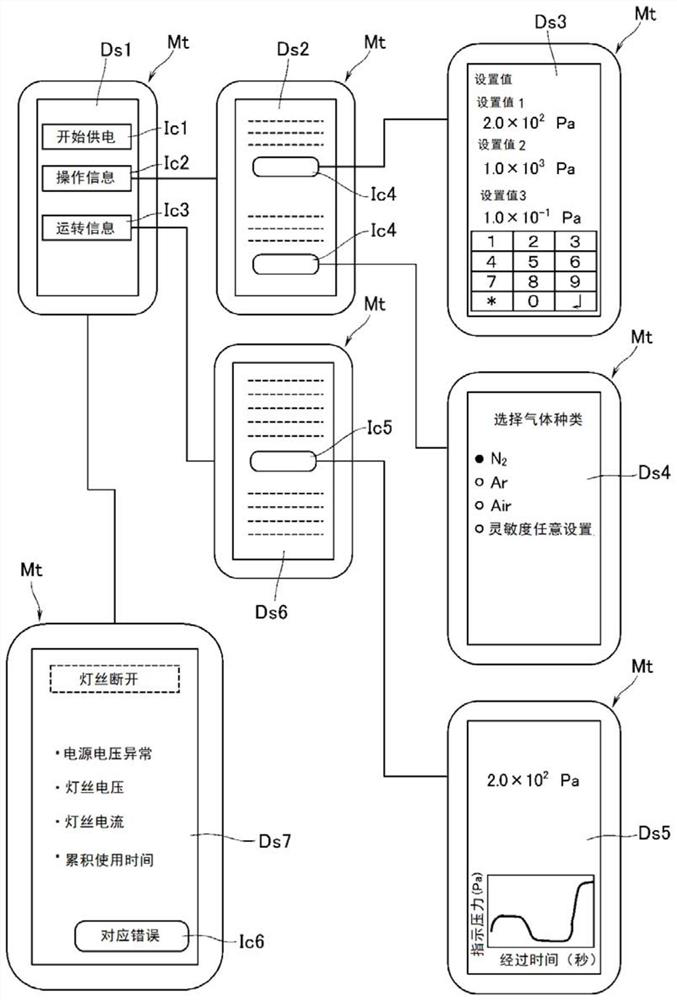

[0019] Refer figure 1 with figure 2 , PG Pirani gauge has a body 1, a pipe body provided with a later-described sensor elements constituting the sensor portion 2 has a flange which can be mounted to a vacuum chamber in which one side Vc 2a. like figure 2 (A), the tube body 2 having a sensor 21 such as a filament of platinum material. On the other hand, if figure 2 (B), in the main body 1 includes: a sensor section 20, which operates receiving a power supply; microcomputer 30 includes a control unit and a memory, which supplies power to the sensor section 20, and input from the sensor unit 20 is performed , and outputs a predetermined signal; a first power supply circuit portion 40, which recei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com