Travel trolley

A technology for trolleys and workpieces, applied in auxiliary welding equipment, welding equipment, manufacturing tools, etc., can solve problems such as changing working positions, and achieve the effect of maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

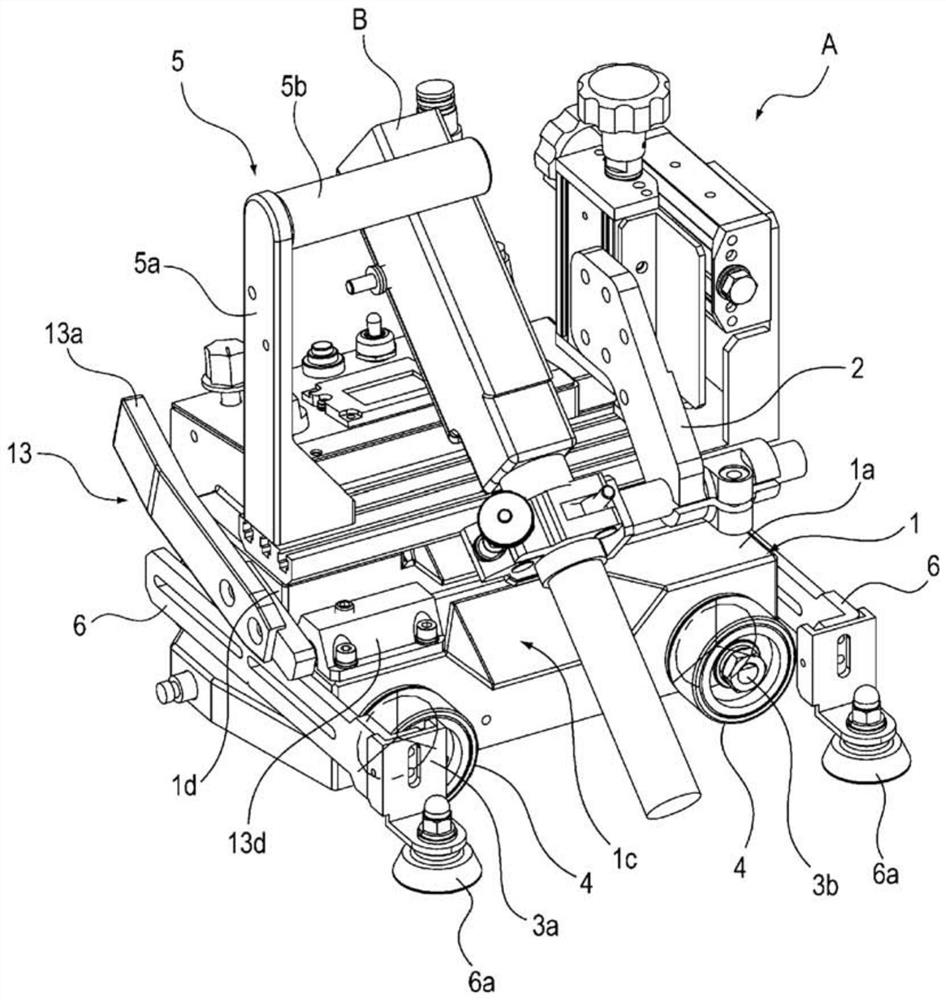

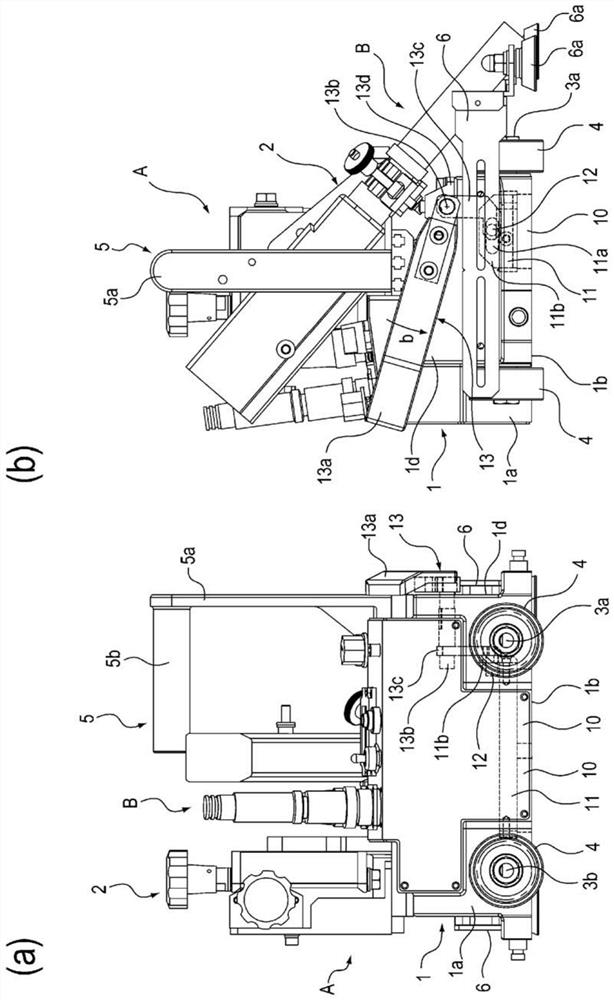

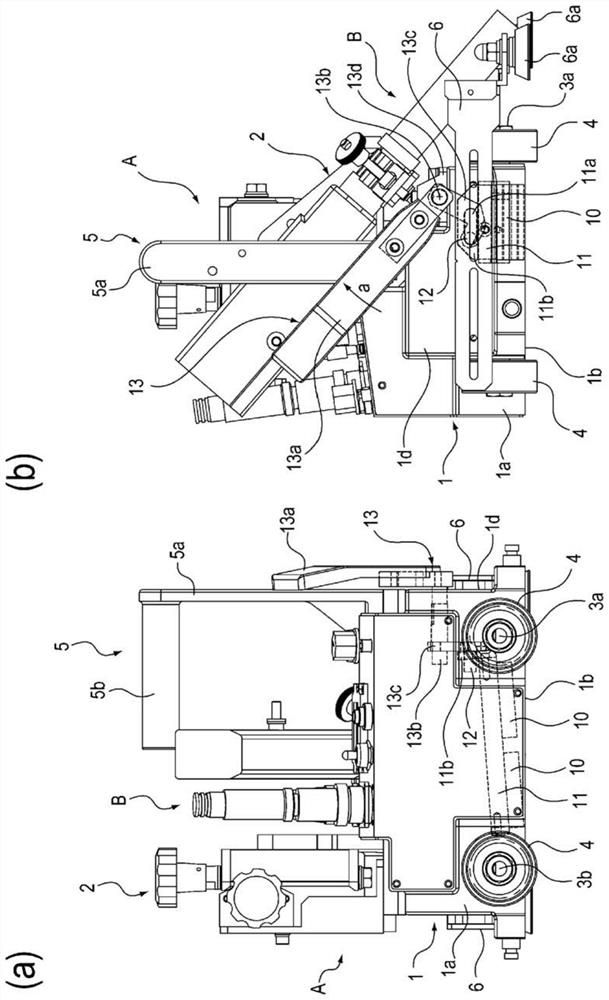

[0029] Hereinafter, the structure of the traveling vehicle of the present invention will be described. The traveling carriage of the present invention is equipped with a welding torch or a cutting torch, and performs welding processing or cutting processing on a workpiece made of a steel plate (hereinafter referred to as "steel plate"). In particular, when the magnet that can be separated from or approached to the steel plate is located at a position away from the steel plate, the position of the magnet away from the steel plate can be held by attracting the holding member arranged to face the magnet.

[0030] In addition, in the traveling trolley of the present invention, in addition to the operating lever for operating the magnet to move away from or approach the steel plate, it also has a handle portion for supporting the load weight of the traveling trolley. Therefore, when moving the traveling trolley Use the handle to operate the operating lever when it is set at the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com