Iron removal device

A transmission device and accommodating cavity technology, which is applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of clogging pipelines, affecting the qualified rate of products, defective products, etc., and achieving the effect of easy cleaning, fast and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and effect of the present application more clear and definite, the present application will be further described in detail below with reference to the accompanying drawings and examples.

[0018] The present application provides an iron removal device, which can be applied at least in the technical field of papermaking, and is used for removing iron-containing impurities in pulp to prevent iron-containing impurities from being brought into the surface of paper sheets, resulting in poor surface of paper sheets. Of course, it can also be applied to other scenarios where iron-containing impurities need to be removed.

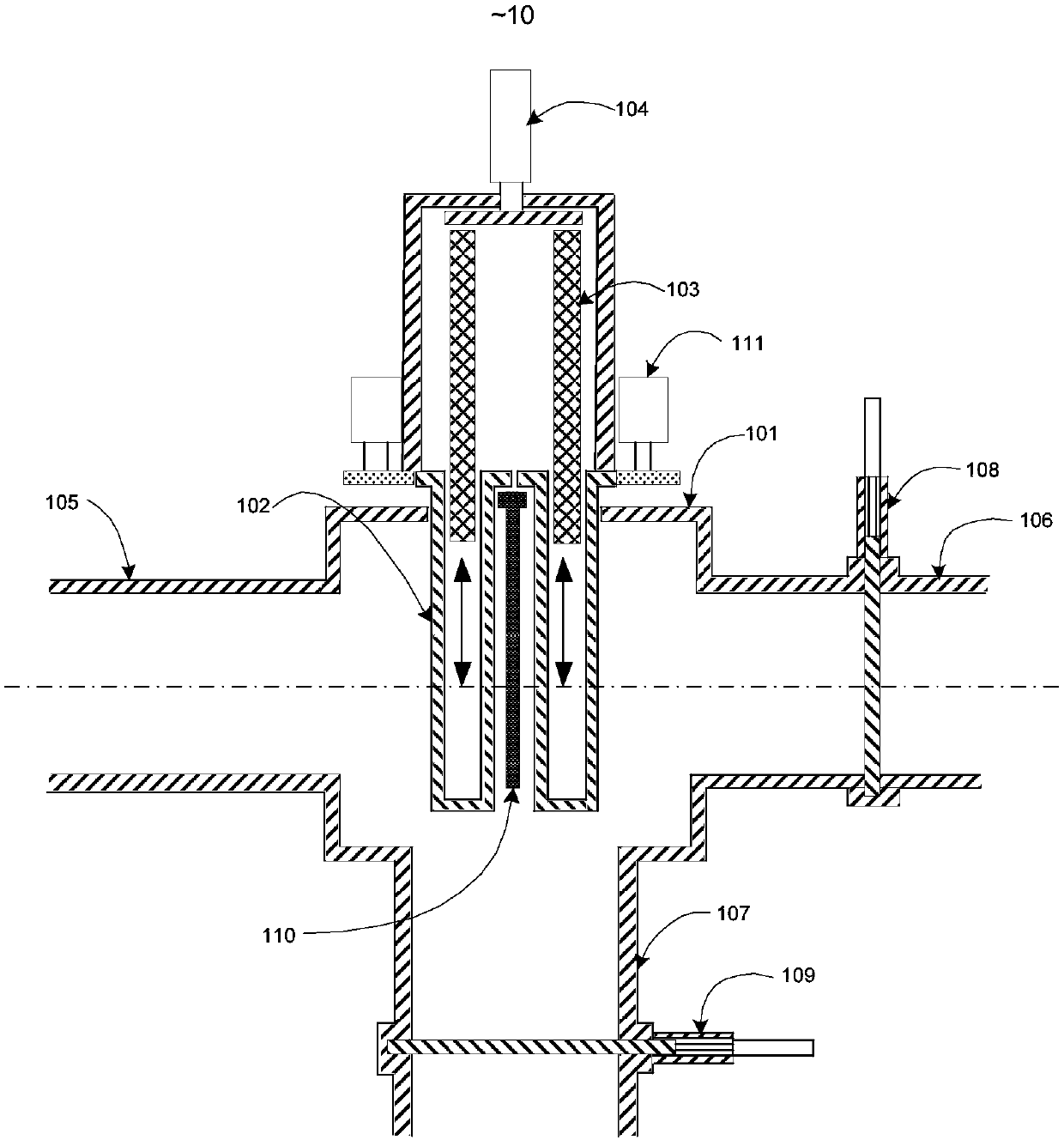

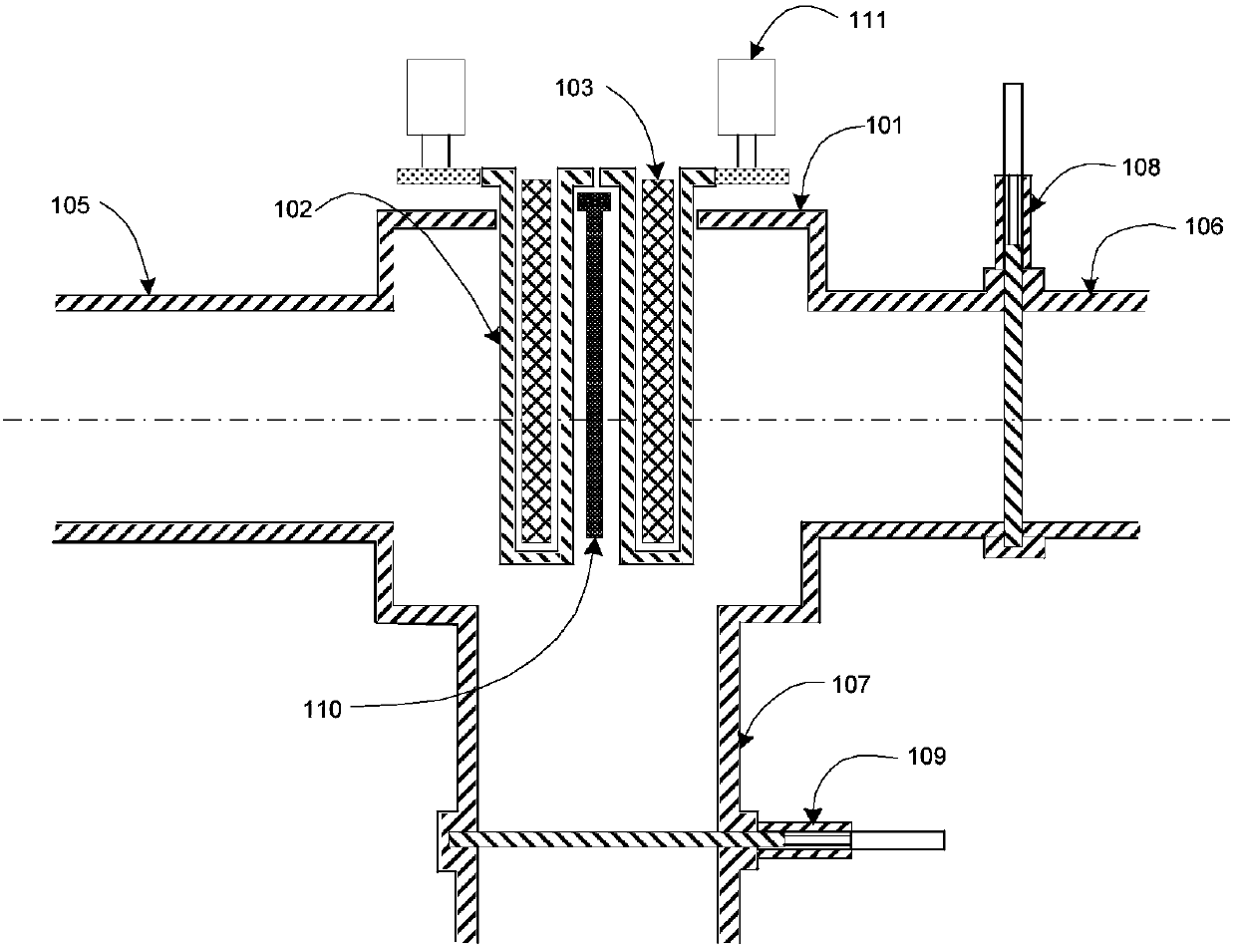

[0019] see figure 1 , figure 1 It is a schematic cross-sectional structure diagram of the first embodiment of the iron removal device of the present application. The iron removal device 10 includes a housing 101, an adsorption cylinder 102 and a magnet 103. The housing 101 is surrounded by an accommodating c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com