Seat frame welding mechanism used for seat iron stand and welding equipment

A welding mechanism and seat technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., to achieve the effect of accurate welding position welding and reliable welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

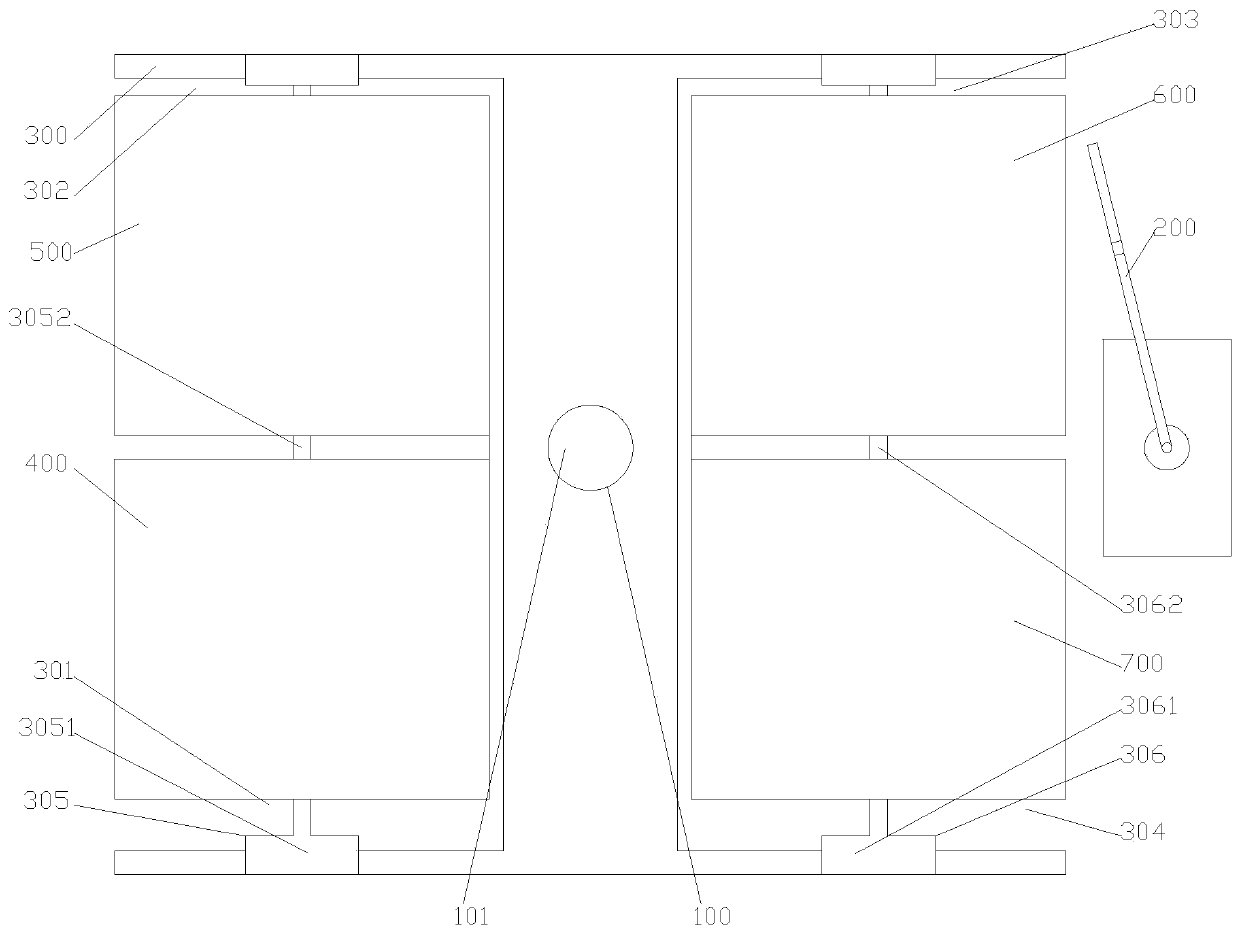

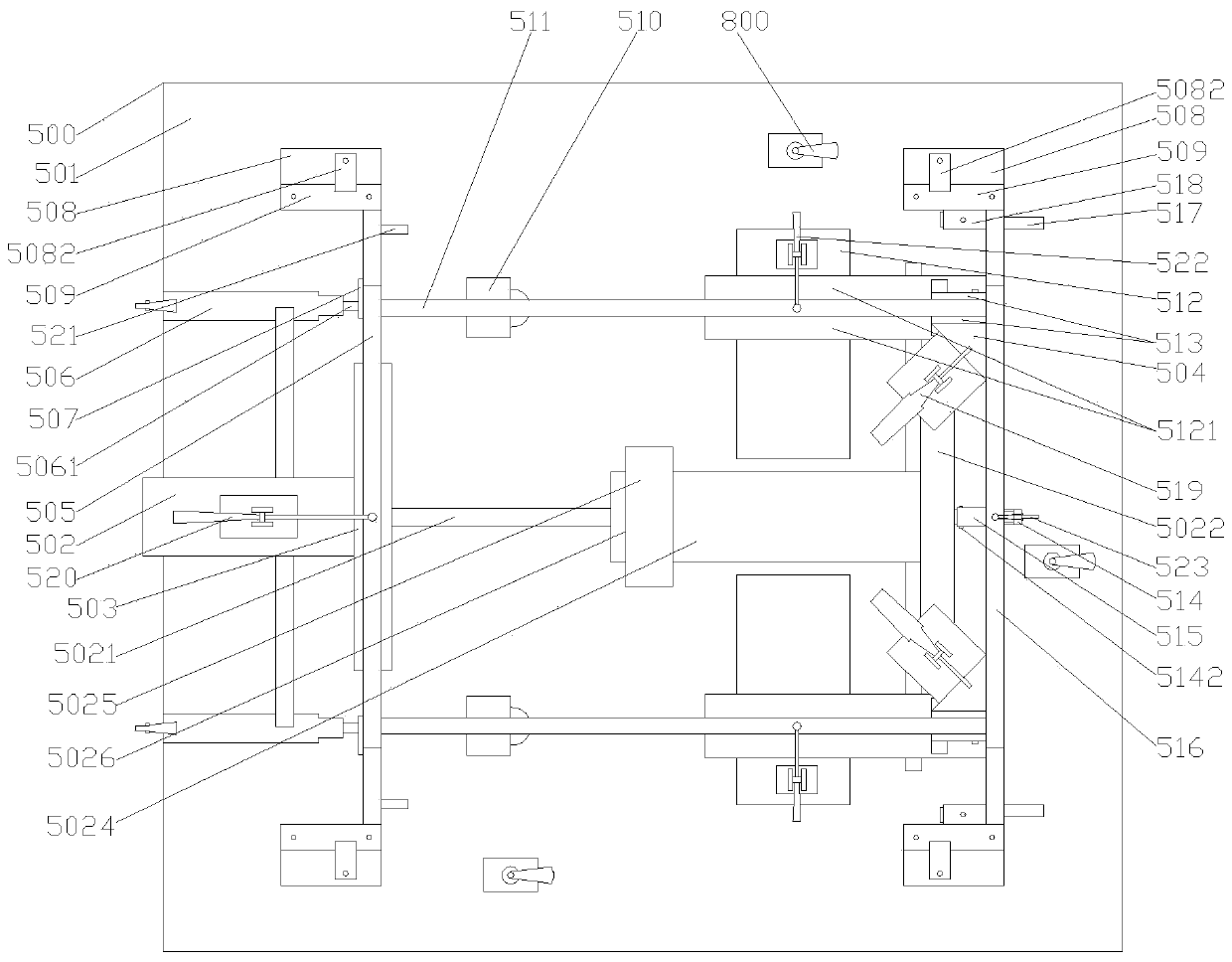

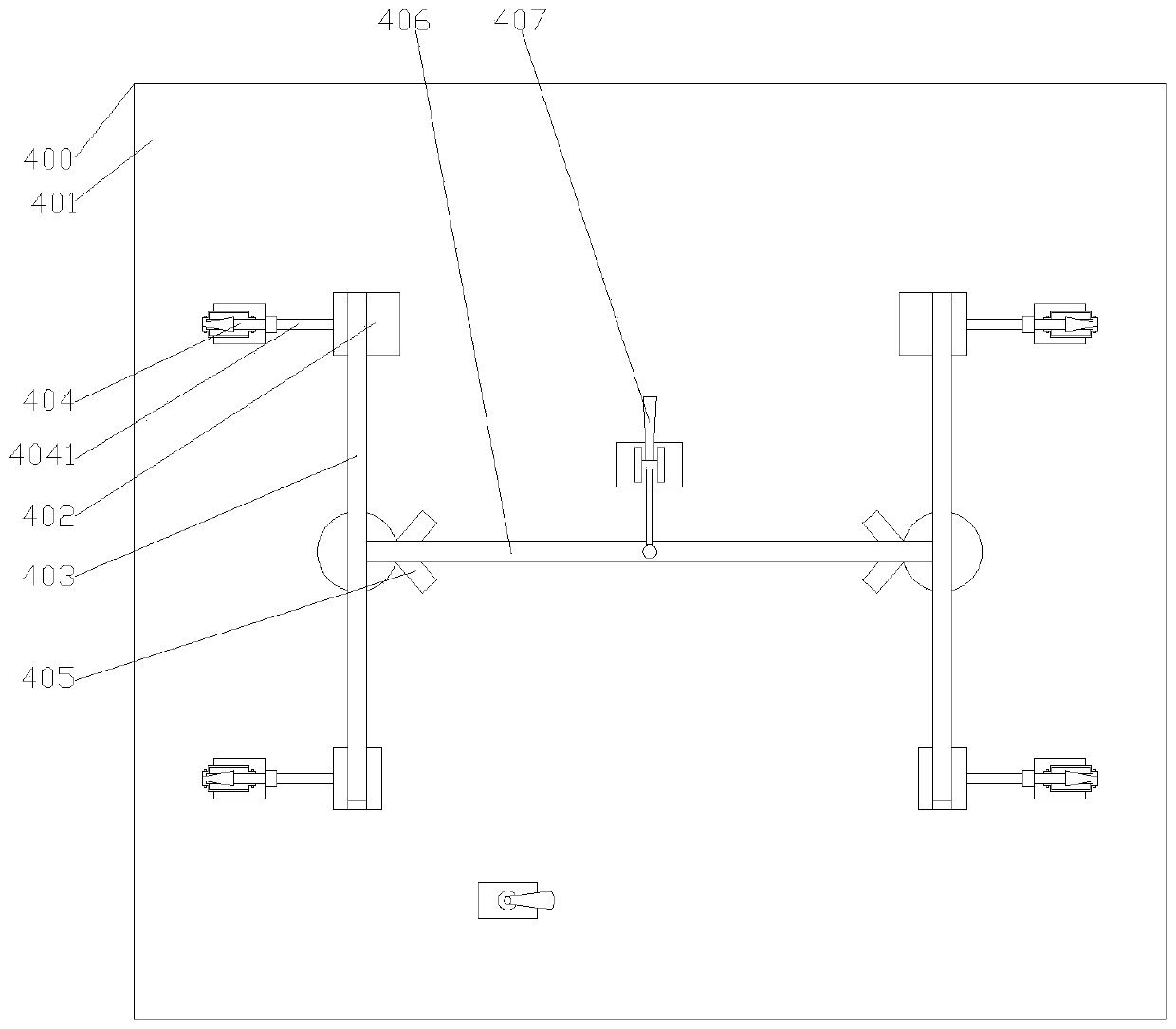

[0039] like figure 2 and Image 6The shown seat frame welding mechanism for the iron frame of the seat, the seat frame includes a first triangular bending piece, a second connecting piece, a third rod, a first mounting piece, a second rod, a third connecting piece, The fourth connecting piece and the first rod; the seat frame welding mechanism includes a first driving device 100 and an arc welding robot arm 200, the driving end of the first driving device is provided with a mounting frame 300, and the mounting frame is provided with a second station 302 , the second station is provided with a seat frame fixing device 500, the arc welding free end of the arc welding mechanical arm corresponds to the contact position of each workpiece on the seat frame fixing device; the seat frame fixing device inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com