Working platform for hardware fitting machining

A work platform and workbench technology, applied in metal processing, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low safety performance, operator threat, etc., and achieve improved structural safety performance, stable left and right movement, and structural design. Ingenious and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

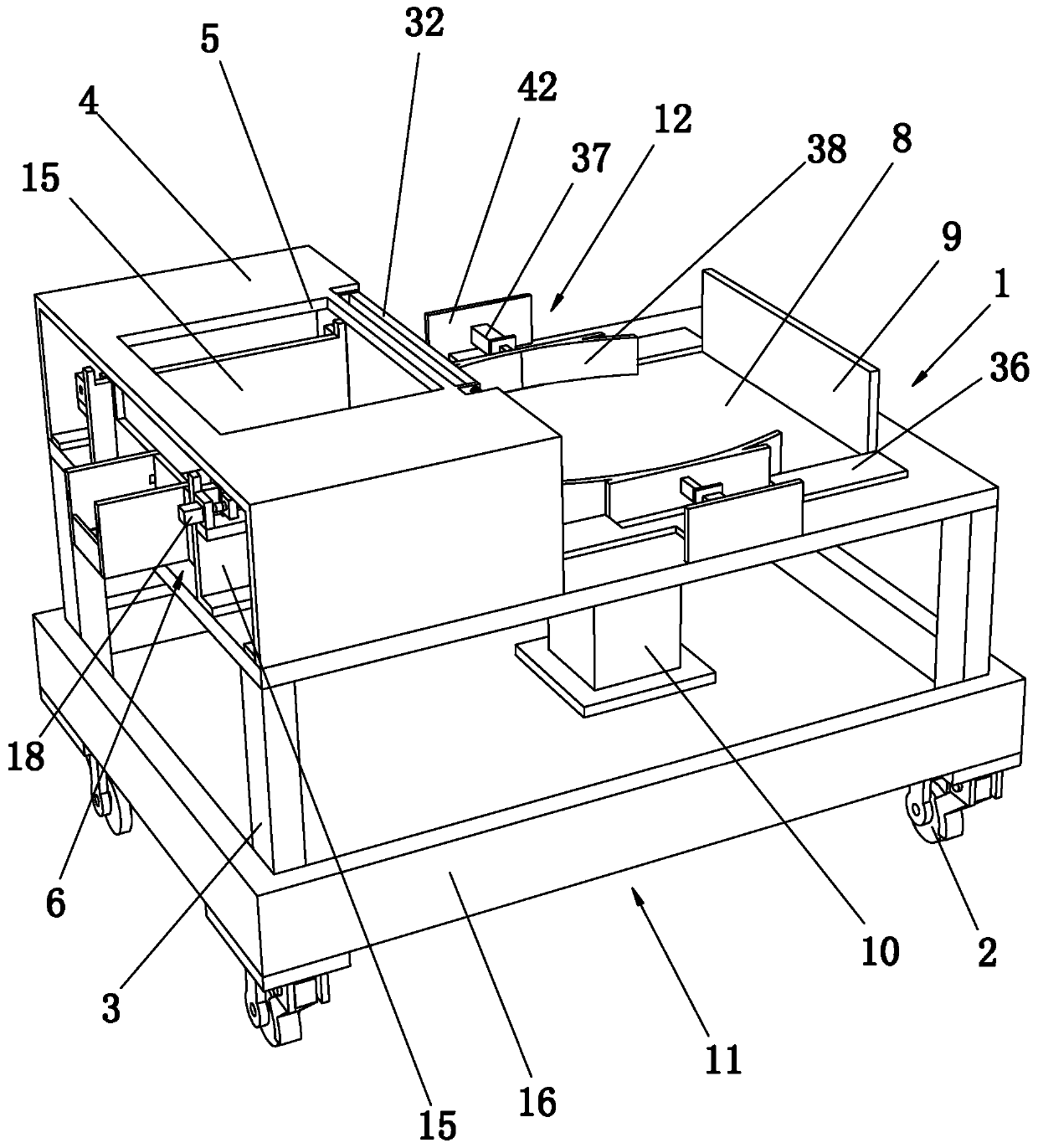

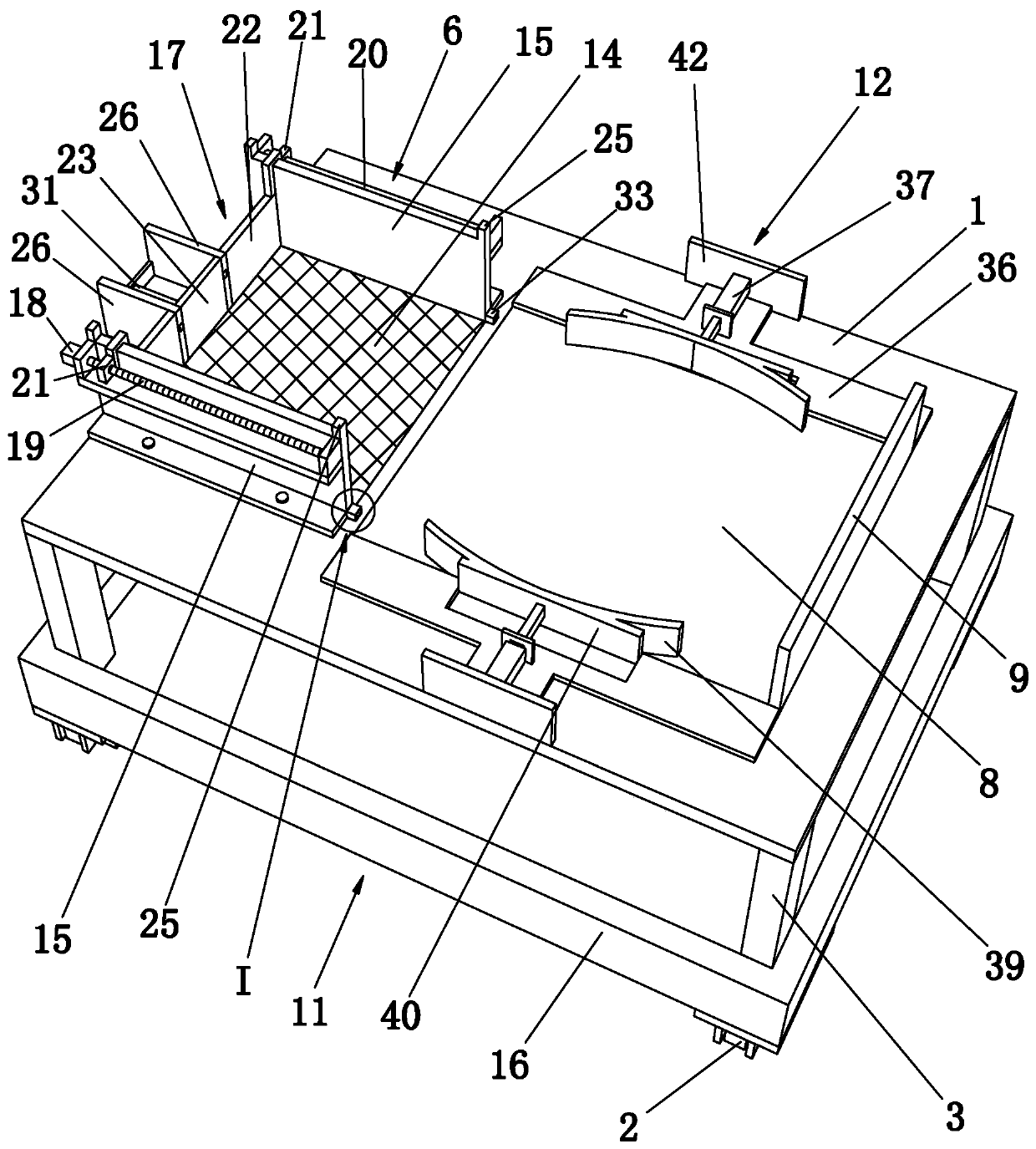

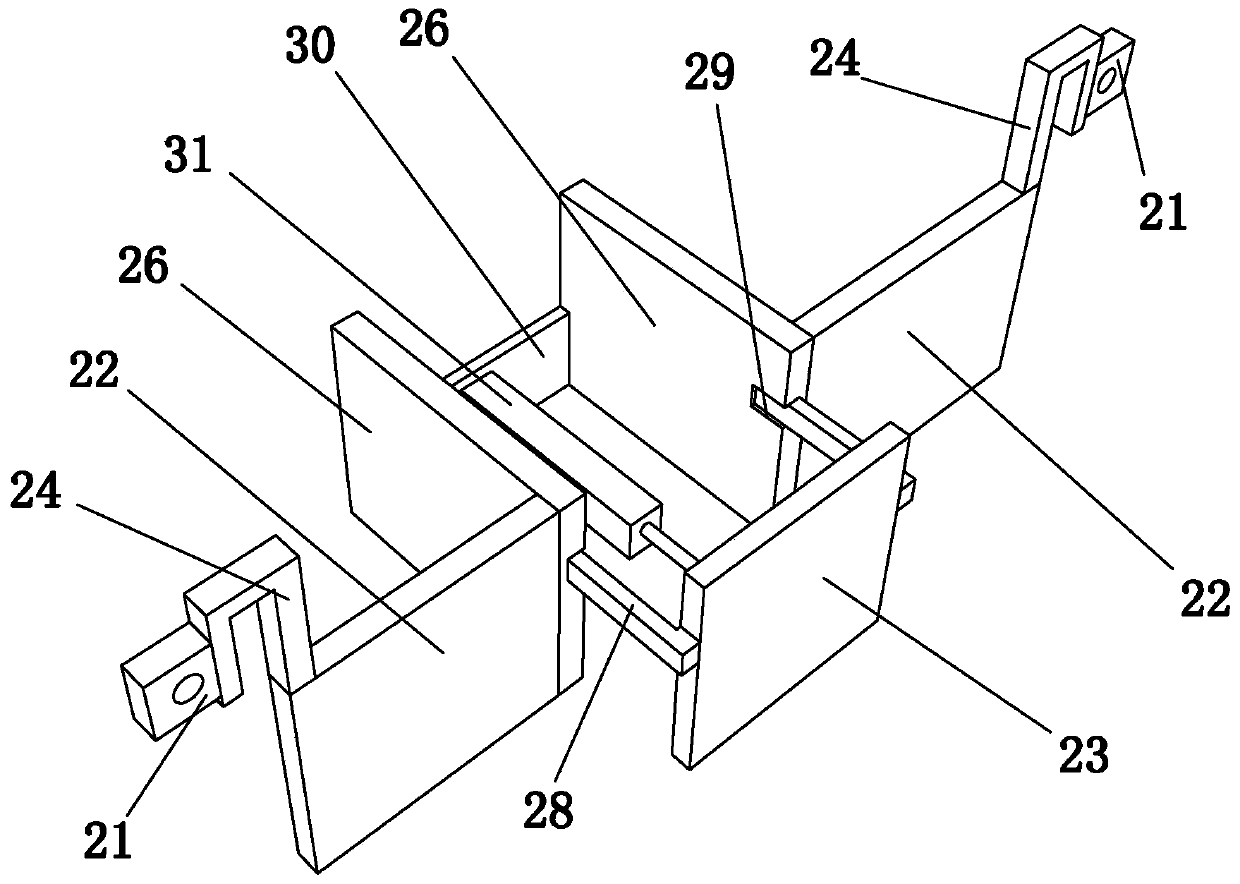

[0029] Such as Figure 1 to Figure 9 As shown, it is a working platform for hardware accessories processing according to the present invention, which includes a working platform 1, which is divided into a feeding area and a processing area, and a protective cover 4 is arranged above the feeding area, and the protective cover 4 is on top The components in the material area are protected to avoid waste chips splashing into the material loading area during the workpiece processing in the processing area, causing certain safety hazards. At the same time, the protective cover 4 makes a clear distinction between the material loading area and the processing area. It is convenient to remind the operator and improve the safety performance of the operation. The protective cover 4 is fixedly connected with the top surface of the feeding area. There is an installation groove 13 at the center of the center, the installation groove 13 is facing the feeding chute 5, and a flexible backing pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com