Automatic material collecting device for quality inspection machine

An automatic material receiving and quality inspection machine technology, applied in thin material handling, transportation and packaging, winding strips, etc. Perfect structural performance, low solution flexibility, and the effect of ensuring transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

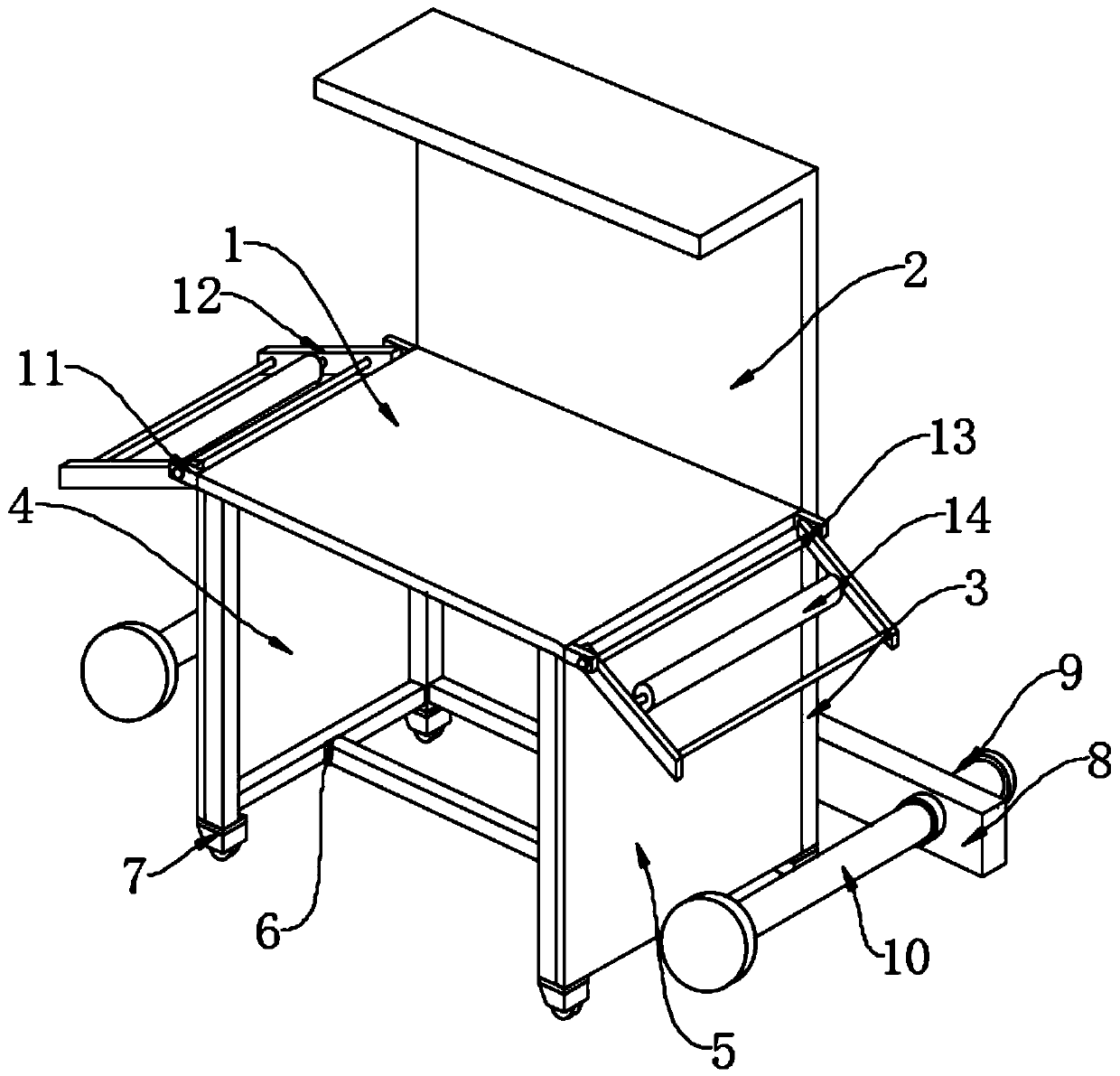

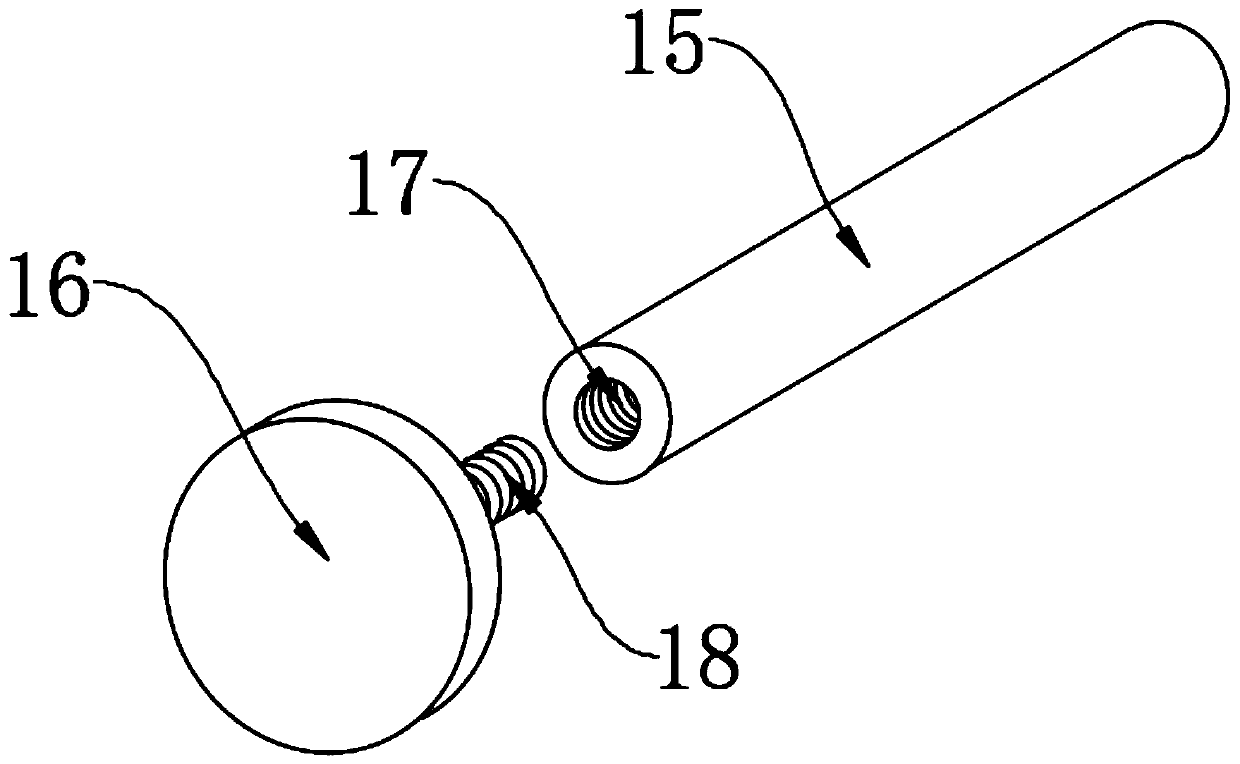

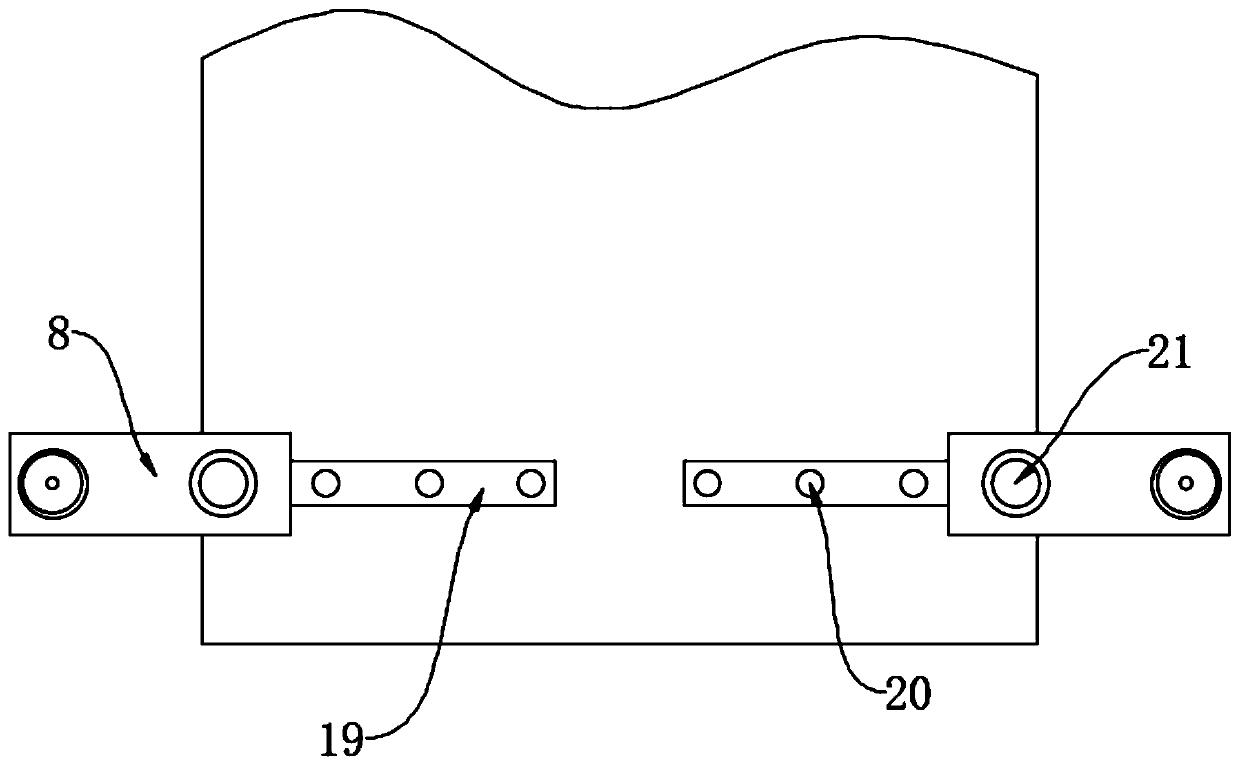

[0019] see Figure 1-3 , an embodiment provided by the present invention: an automatic material receiving device for a quality inspection machine, including a work support main board 1, a rear fixed baffle 2 is installed on the rear end of the work support main board 1, and a rear fixed baffle 2 is installed on the lower end of the rear fixed baffle 2 After installing the fixed plate 3, the side below the work support main board 1 is equipped with a first installation side 4, and the other side below the work support main board 1 is equipped with a second installation side 5, the first installation side 4 and the second installation side 4. The inner side of the inst...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap