Cleaning anticorrosion device for inner wall of oil pipeline

A technology for oil pipelines and anti-corrosion devices, which is applied to spray devices, cleaning hollow objects, liquid spray devices, etc., can solve the problems of increased processing cost, leakage, inconvenience, etc., and achieve the effect of reducing potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

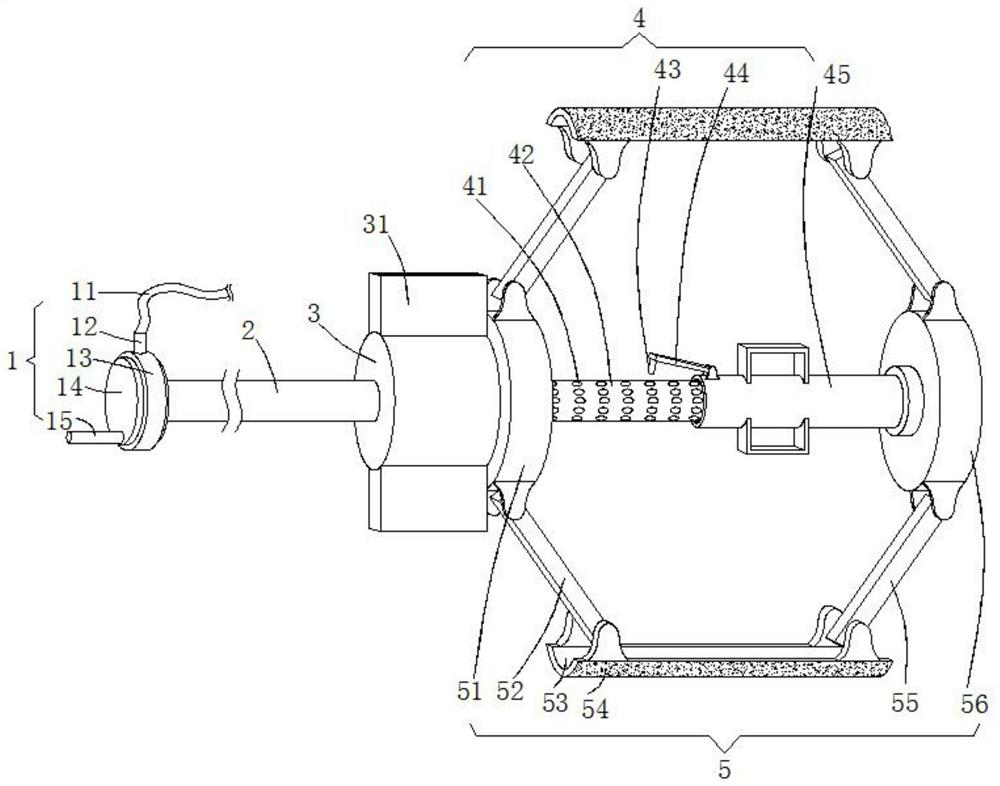

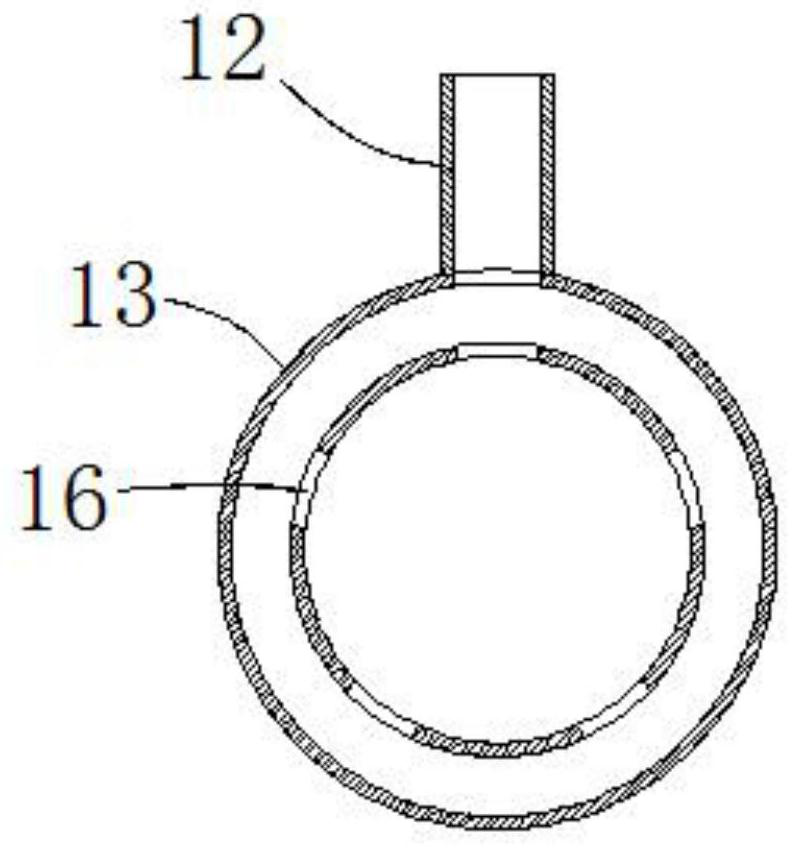

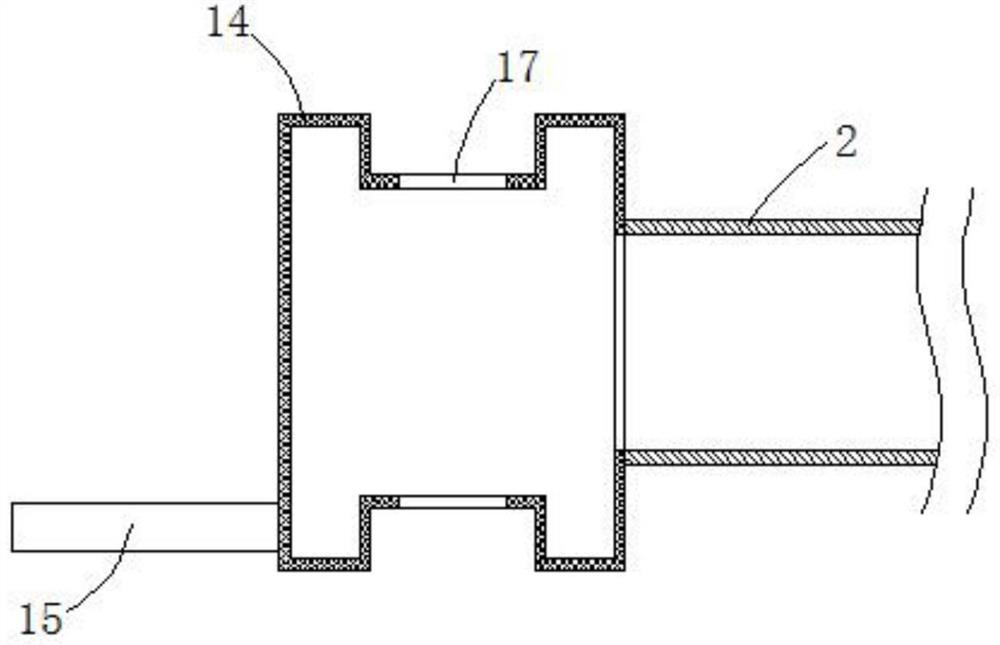

[0025] see Figure 1-4 , this embodiment provides a cleaning and anticorrosion device for the inner wall of an oil pipeline, including a transfer mechanism 1, an adjustment mechanism 4 and a cleaning mechanism 5, the transfer mechanism 1 includes a hollow socket sleeve 13 and an I-shaped hollow sleeve 14, The inner cavity of the hollow socket sleeve 13 is rotatably socketed in the middle section of the outer wall of the I-shaped hollow sleeve 14. The right end surface of the I-shaped hollow sleeve 14 is connected with a hollow transmission rod 2 communicating with the inner cavity. The right end of the hollow transmission rod 2 Interconnected paint transfer boxes 3 are connected, and the cleaning mechanism 5 includes a first hinged seat 51, a second hinged seat 56, two first hinged rods 52, two second hinged rods 55 and two mutually symmetrical arcs. The PVC scraper 53, the adjustment mechanism 4 includes a threaded post 42 and a threaded sleeve 45, the threaded post 42 is rot...

Embodiment 2

[0032] see Figure 1-4 , further improvements have been made on the basis of Example 1:

[0033] The outer wall of the threaded column 42 is axially provided with several limiting grooves 41 distributed in a ring, the outer wall of the left end of the threaded sleeve 45 is hinged with a limiting rod 44, and the bottom surface of the tip of the limiting rod 44 is provided with each limiting groove. The limit post 43 that 41 inner chambers are matched and plugged in is plugged with the limit slot 41 by the stop post 43, so that after the threaded post 42 is adjusted to be positioned at the inner cavity position of the threaded sleeve 45, the threaded post 42 and the threaded sleeve There will be no relative rotation between the cylinders 45, which will not affect the cleaning operation;

[0034] The outer wall of the threaded sleeve 45 is provided with up-and-down symmetrical handles, which are convenient for assisting the rotation of the threaded sleeve 45 by setting the handl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap