An integrated collecting device for shredding flaky kelp

An all-in-one, kelp technology, applied in metal processing and other directions, can solve the problems of affecting work efficiency, laborious operation, easy fatigue, etc., and achieve the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] see figure 1 with figure 2 , an integrated harvesting device for flaky kelp shreds, including a base 1, a hollow cylinder 2, a cross bar 3, a frame body 4, a cutting mechanism 5 and a driving mechanism 6, and the hollow cylinder is fixed in the middle on the left side of the top of the base 1 2. There is a driving mechanism 6 between the left side of the hollow cylinder 2 and the base 1. Two crossbars 3 are fixedly connected to the middle of the outer right side of the hollow cylinder 2. Two crossbars 3 are hinged between the right ends of the two crossbars. The frame body 4, a cutting mechanism 5 is provided between the frame body 4 and the hollow cylinder 2.

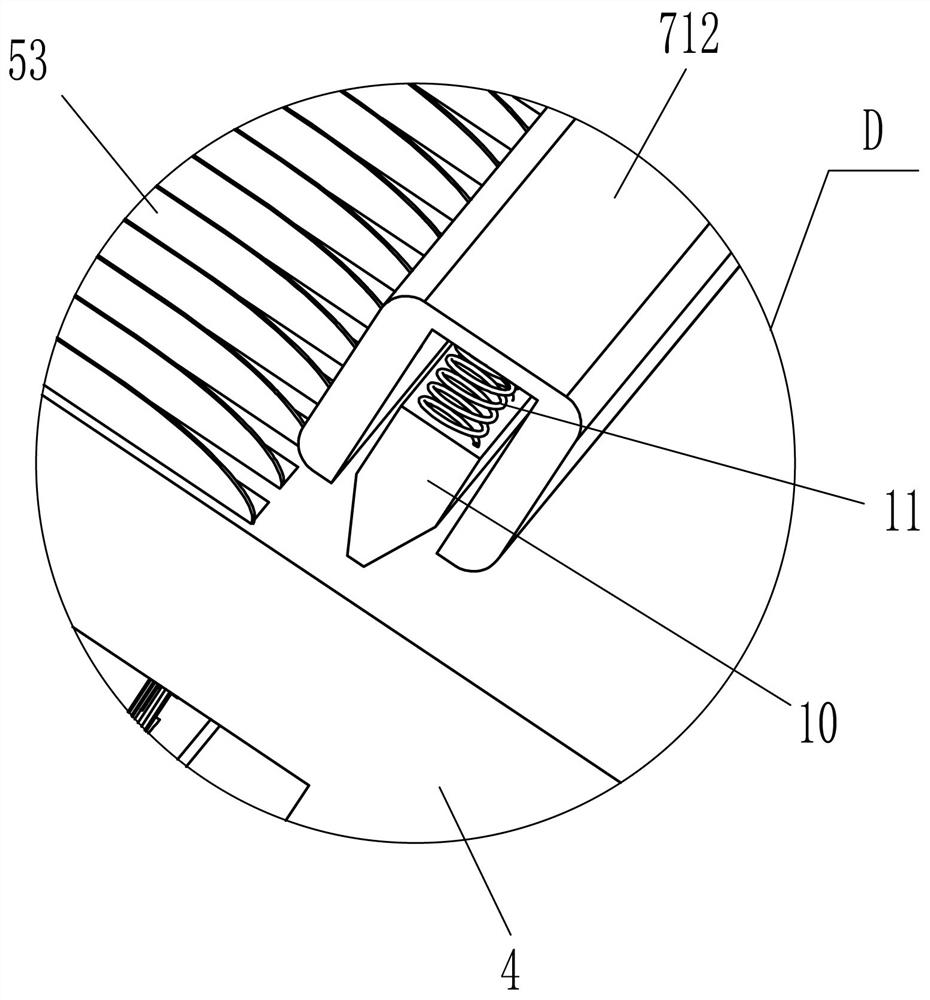

[0026] The cutting mechanism 5 includes an arc piston rod 51, a first spring 52, a cutter plate 53, a guide rod 54 and a second spring 55, and the hollow cylinder 2 is slidingly provided with an arc piston rod 51 at both ends of the arc. A first spring 52 is wound between the middle part of the piston rod 51 ...

Embodiment 2

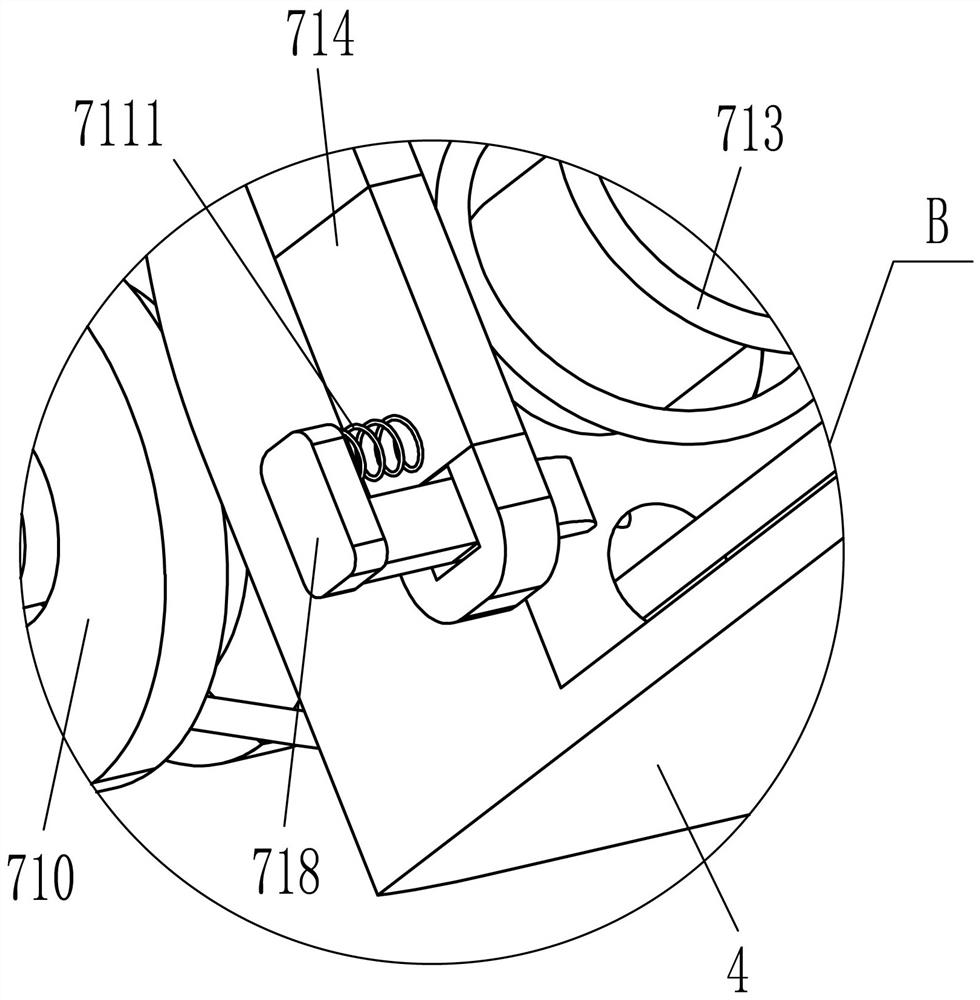

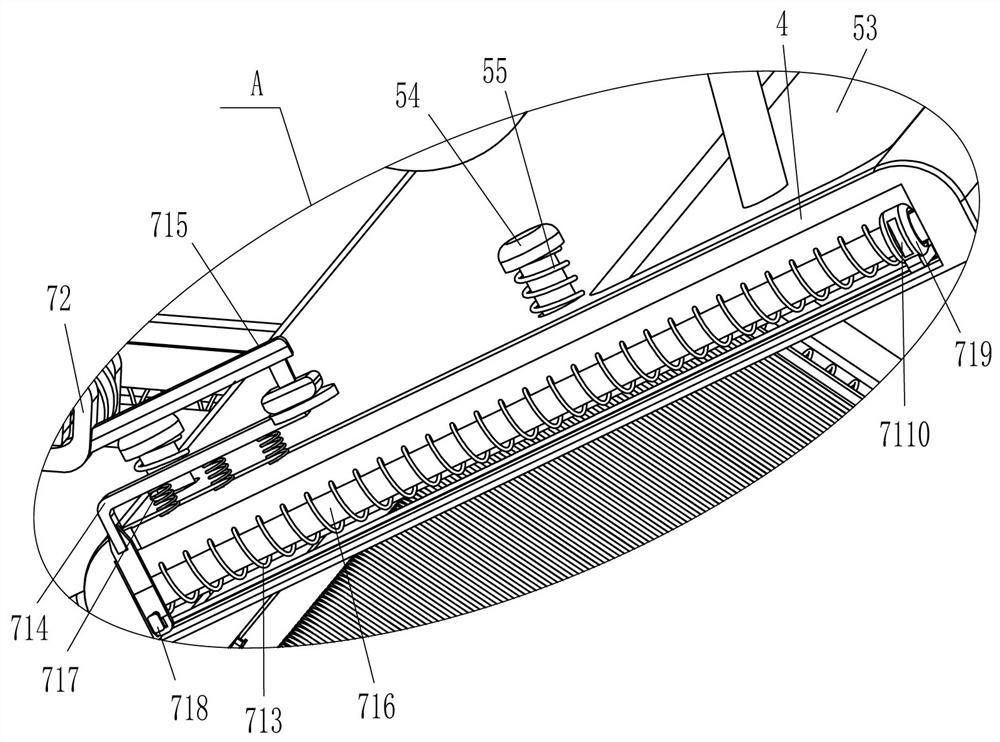

[0032] see figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, a scraping mechanism 7 is also included, and the scraping mechanism 7 includes a support frame 71, a guide frame 72, a slider 73, a first guide wheel 74, The third spring 75, rotating shaft 76, winding wheel 77, backguy 78, gear 79, the second lead wheel 710, tooth piece 711, fixed scraper 712, the 4th spring 713, L-shaped plate 714, L-shaped contact plate 715, Guide rod 716, the fifth spring 717, movable block 718, sliding sleeve 719 and the sixth spring 7111, two guide frames 72 are fixedly connected to the upper and lower parts on the front and rear sides of the hollow cylinder 2, and the guide frame 72 is of sliding type. A slide block 73 is provided, a third spring 75 is connected between the left side of the slide block 73 and the inner left side of the guide frame 72, and a first guide pulley...

Embodiment 3

[0035] see Figure 4 , Figure 8 with Figure 9 Compared with Embodiment 1 and Embodiment 2, the main difference of this embodiment is that in this embodiment, a hook 8 and a seventh spring 9 are also included, and there are slide grooves 91 on the front, rear and both sides of the left side of the lower frame body 4. A hook 8 is slidingly provided in the chute 91, and a seventh spring 9 is connected between the left end of the hook 8 and the left side of the chute 91.

[0036] It also includes a movable scraper 10 and an eighth spring 11. The movable scraper 10 is slidingly arranged in the middle of the outer surface of the fixed scraper 712 on the upper and lower sides, and the inner surface of the movable scraper 10 is connected with the inner surface of the fixed scraper 712. Eighth spring 11.

[0037] When the operator puts the sea-tangle in the lower frame 4, the sea-tangle can be hung on the front and rear hooks 8, because of the effect of the seventh spring 9, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com