Bobbin creel integrated structure used on rotor spinning

A creel and integrated technology, applied in the field of creel, can solve the problems of unstable positioning of the flip arm, inconvenient opening operation, low production efficiency, etc., to improve production efficiency and convenience of use, improve horizontal strength, facilitate production and effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

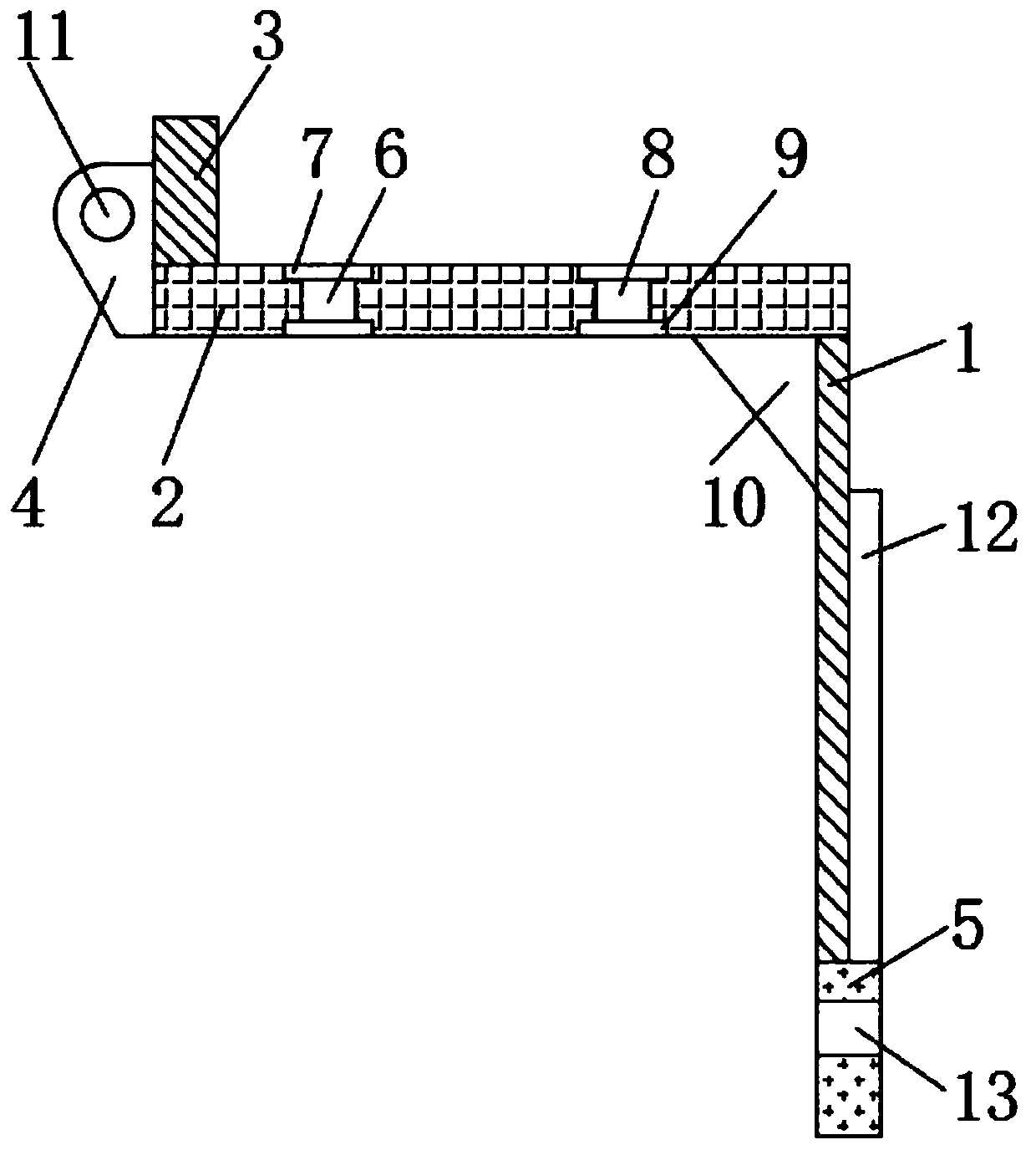

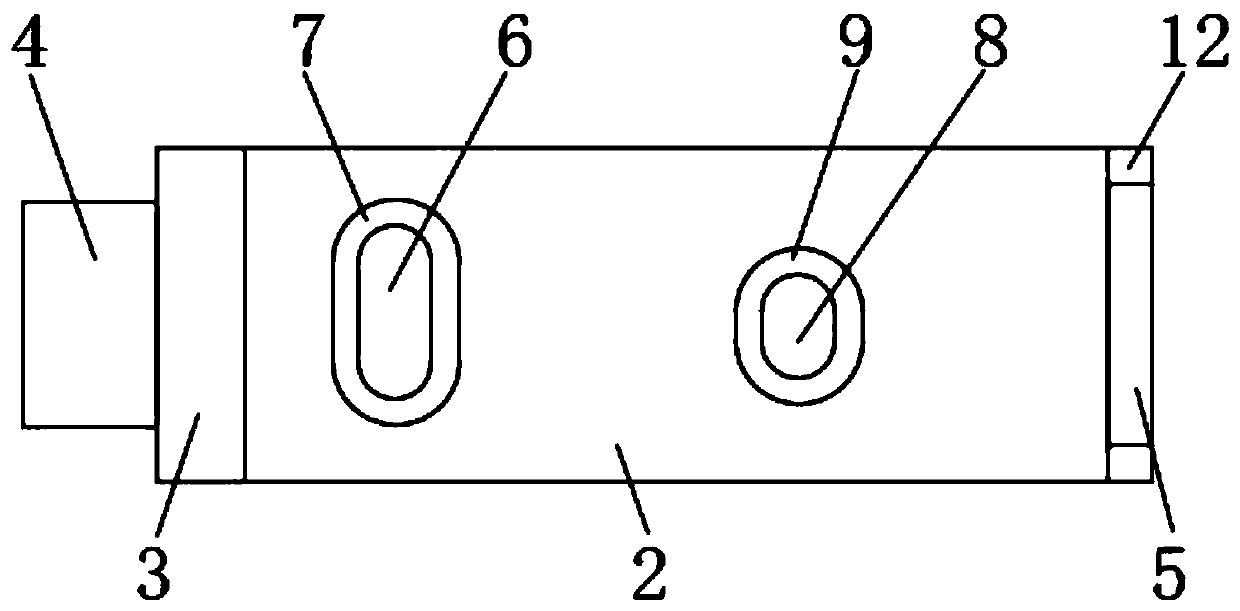

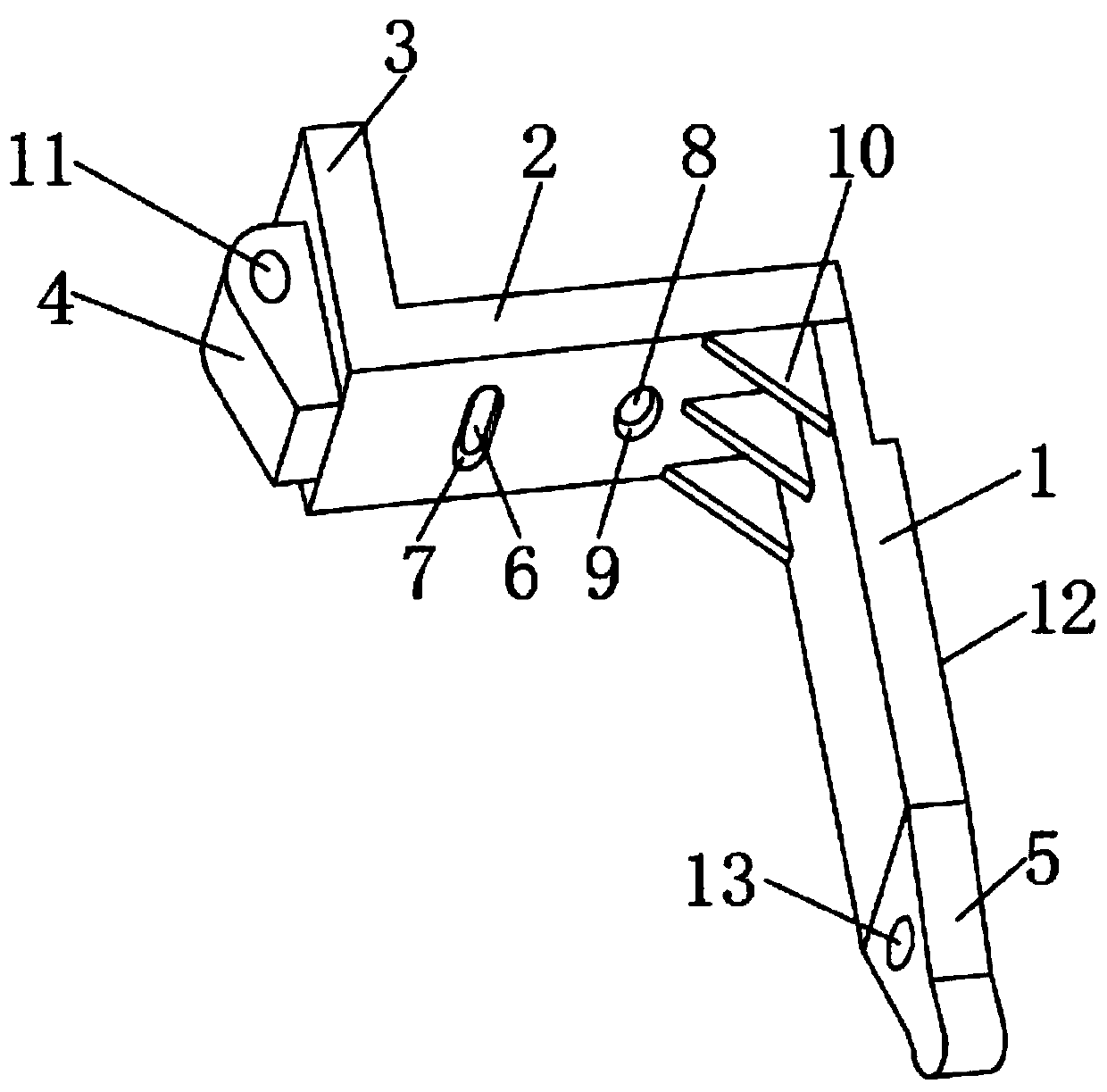

[0019] Such as Figure 1-3 , the present invention includes a straight arm plate 1, the top of the straight arm plate 1 is fixedly connected with a cross arm plate 2, because the left side of the top of the cross arm plate 2 is provided with a first installation hole 6, and the first installation hole 6 is arranged in an oval shape, Both the top and the bottom of the first installation hole 6 are provided with a first inserting groove 7, which is designed to facilitate the user to install the bolt through the first inserting groove 7 through the setting of the first installation hole 6 and the first inserting groove 7. Finally, ensure that the surface of the cross arm plate is smooth, and at the same time, the ellipse of the first mounting hole 6 can be used for horizontal fine-tuning installation of the bolts. Because the right side of the to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com