Blasting vibration speed amplitude and direction correction method

A technology of velocity amplitude and blasting vibration, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problem of not correctly reflecting the hazards of blasting to surrounding buildings, and achieve the effect of ensuring safety, production and normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

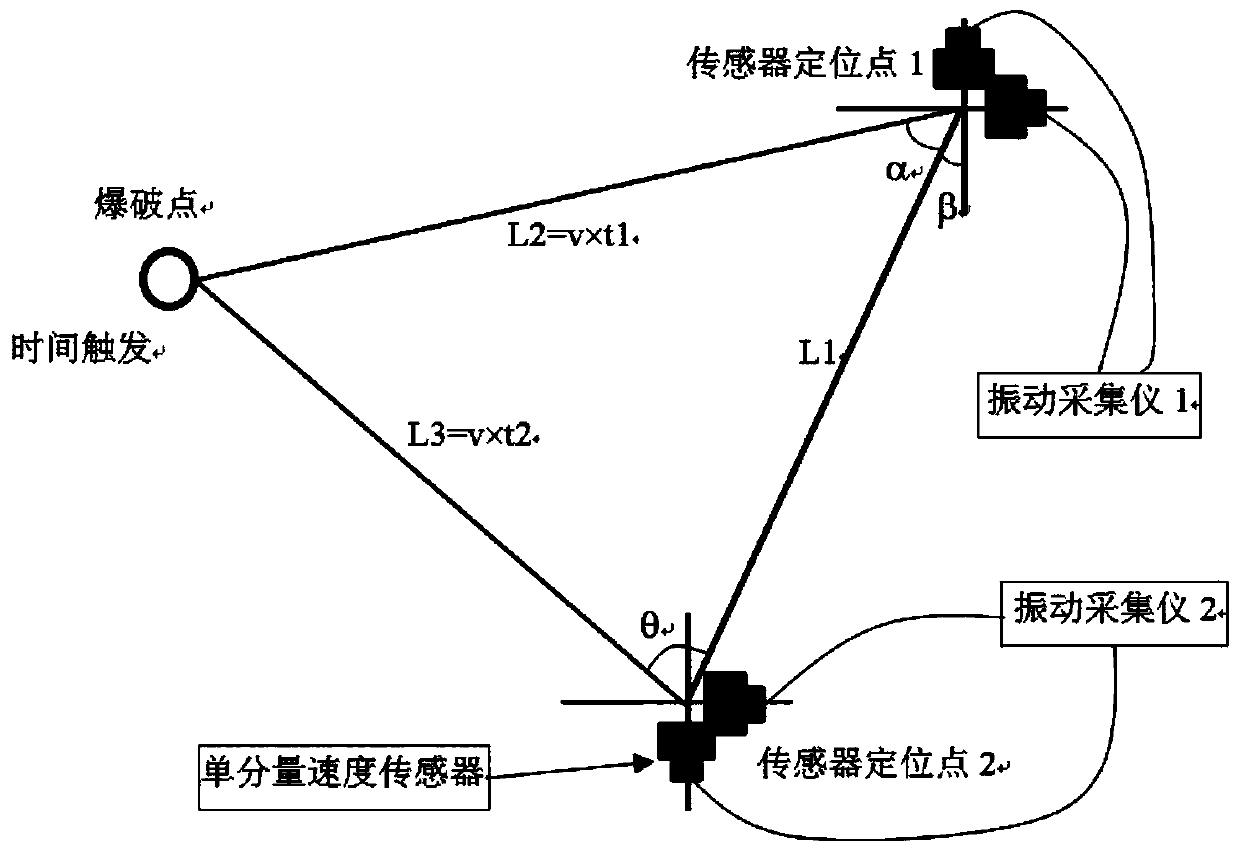

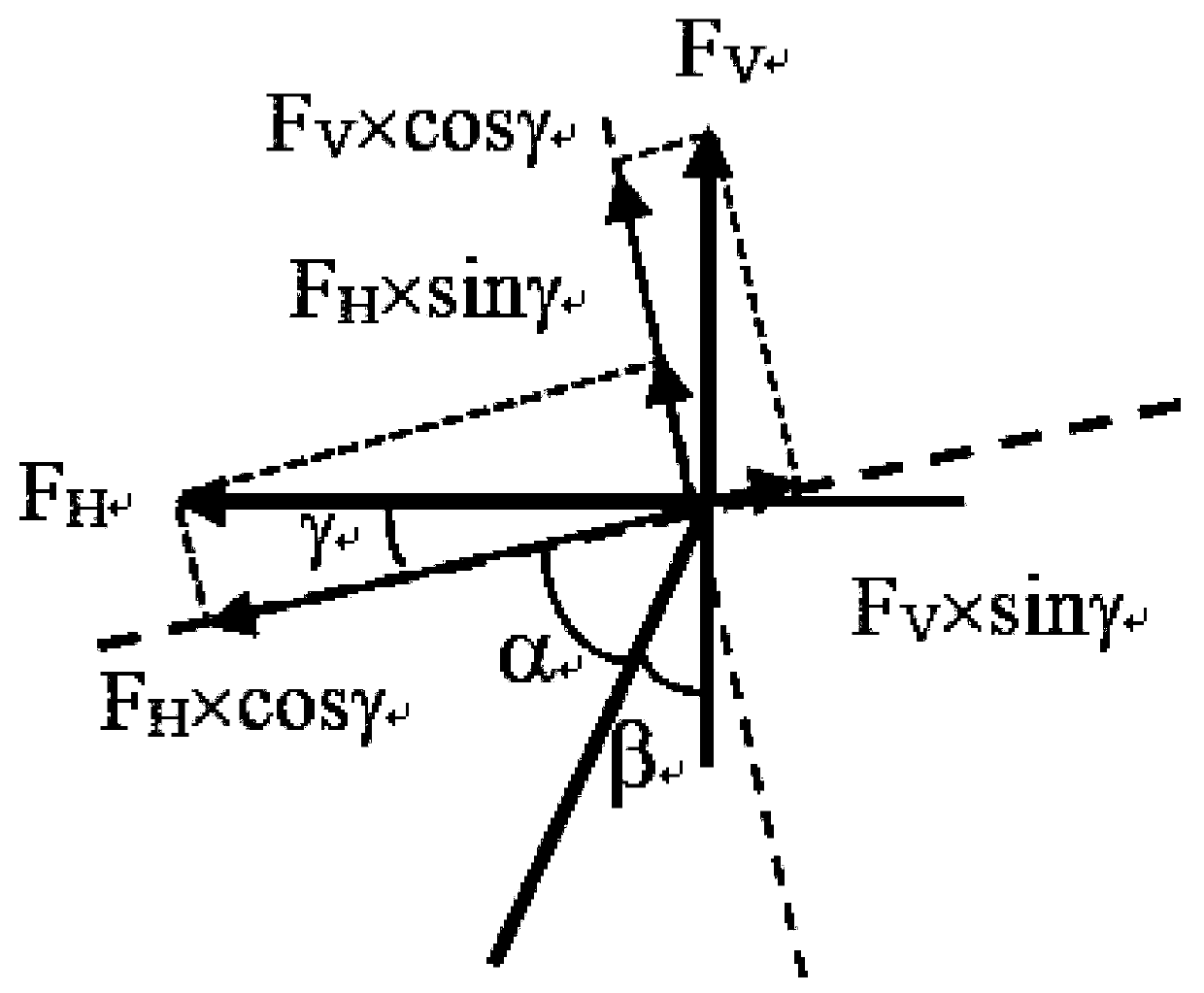

[0034] Attached below Figure 1-2 The method of correcting the amplitude and direction of blasting vibration velocity is further explained.

[0035] The main purpose of the present invention is to overcome the above-mentioned defects in the prior art, and propose a prediction method that can accurately give the amplitude of the vibration velocity, the direction of the vibration velocity and the blasting point. The present invention adopts following technical scheme:

[0036] The hardware system includes: a vibration acquisition instrument, a single-component speed sensor and a time trigger device. Preferably, the time trigger device adopts a trigger line. After the blast occurs, the time trigger is started when the trigger line breaks, so as to perform time acquisition.

[0037] The position points involved include: sensor positioning point 1, sensor positioning point 2, and blasting point.

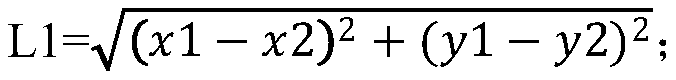

[0038] Concrete technical scheme implementation mode comprises the following steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com