Vehicle door C-pillar parting sealing strip structure

A technology of sealing strips and seams, which is applied in the field of interior and exterior decoration of automobiles. It can solve problems such as the sealing strips falling out, the interference of the mushroom head connection structure is small, and the sealing strips are not installed in place, so as to improve the sealing performance and avoid workers complaining. The effect of saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further illustrate the technical means and functions adopted by the present invention to achieve the intended purpose of the invention, the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

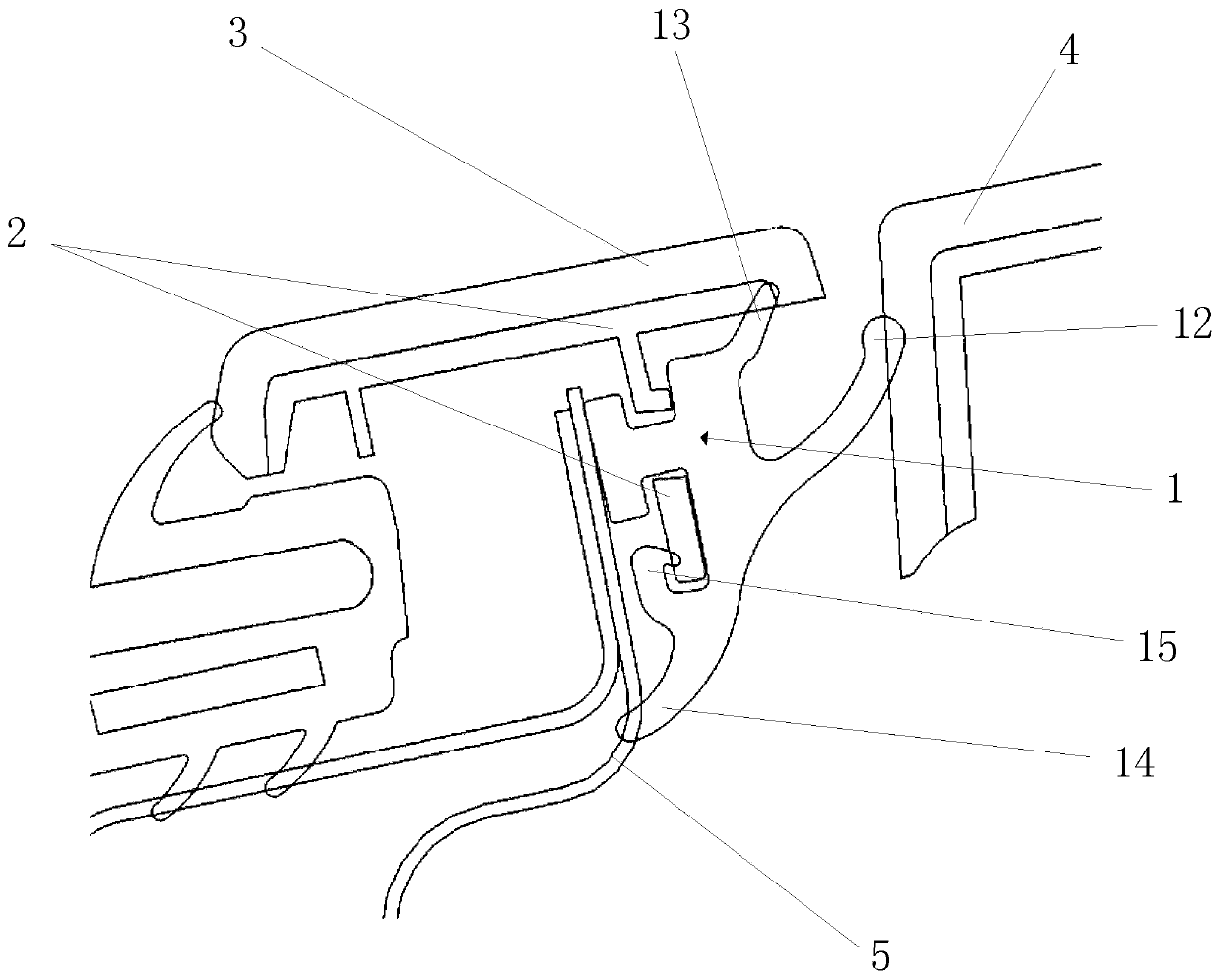

[0024] The car door C-pillar split seal structure of the present invention is located between the C-pillar high-gloss trim panel 3 and the D-pillar high-gloss trim panel 4 in the vehicle body length direction, and is located inside the C-pillar high-gloss trim panel 3 in the vehicle body width direction.

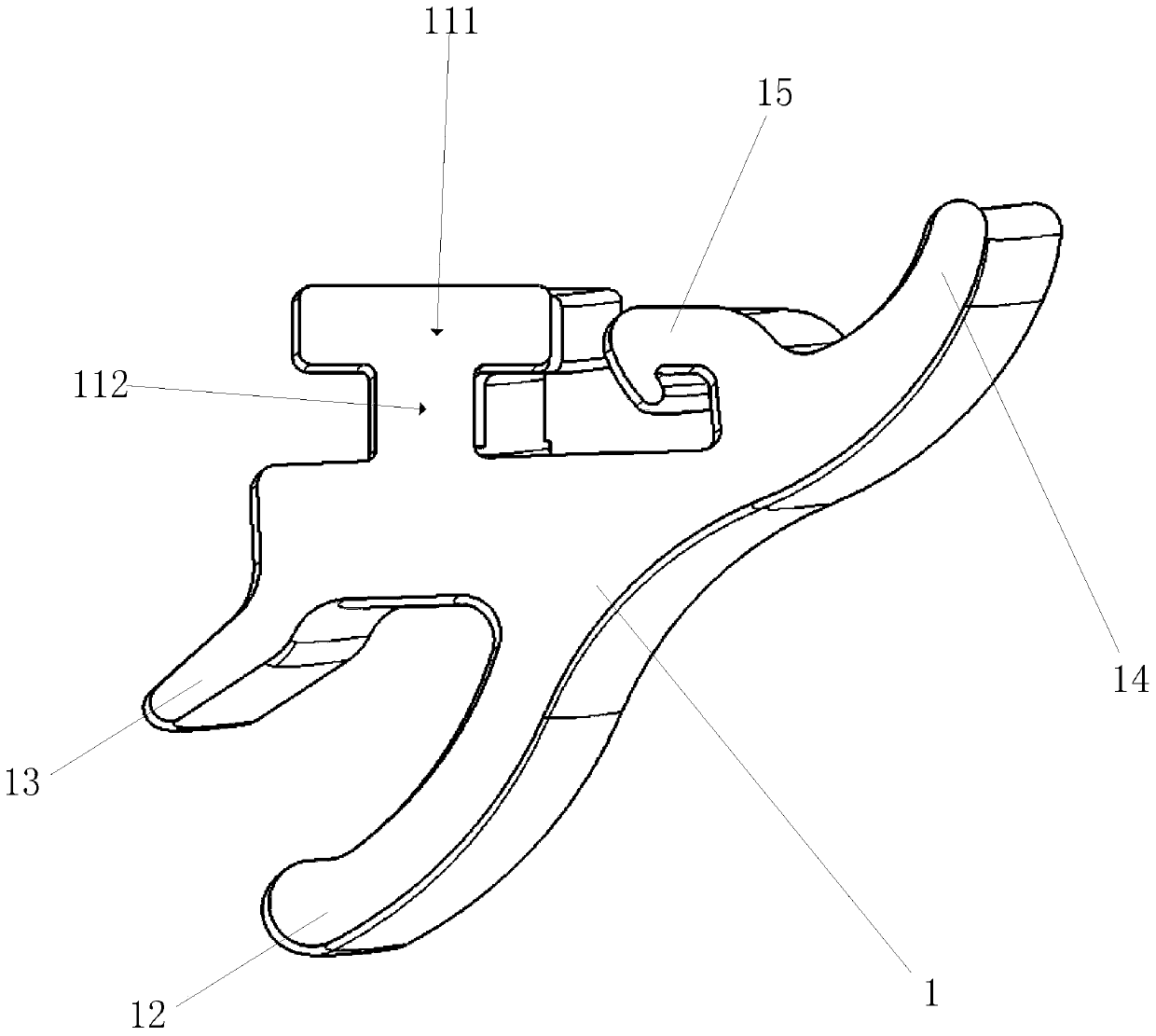

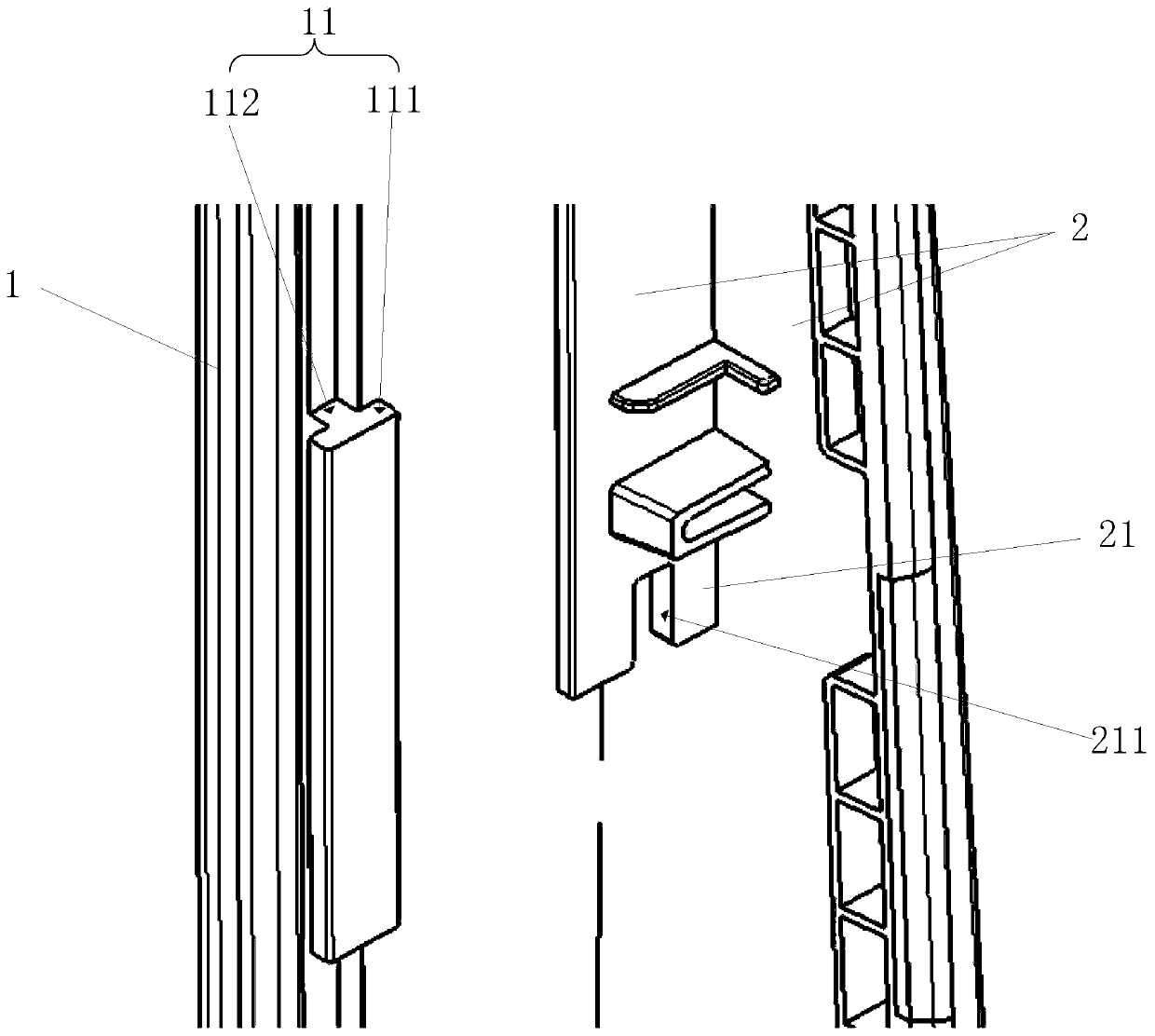

[0025] see Figure 1 to Figure 2 , the car door C-pillar split sealing strip structure of the present invention includes a sealing strip 1 and a decorative panel 2, the decorative panel 2 is located on the inner side of the C-pillar high-gloss decorative panel 3 and is offset against the C-pillar high-gloss decorative panel 3, and the sealing strip 1 is in three directions Respectively offset w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap