Intelligent orthotropic steel bridge deck fatigue cracking detection robot

A steel bridge deck, fatigue cracking technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of heavy workload, time-consuming, wrong detection, etc., and achieve the effect of maintaining stable operation and stable and accurate transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

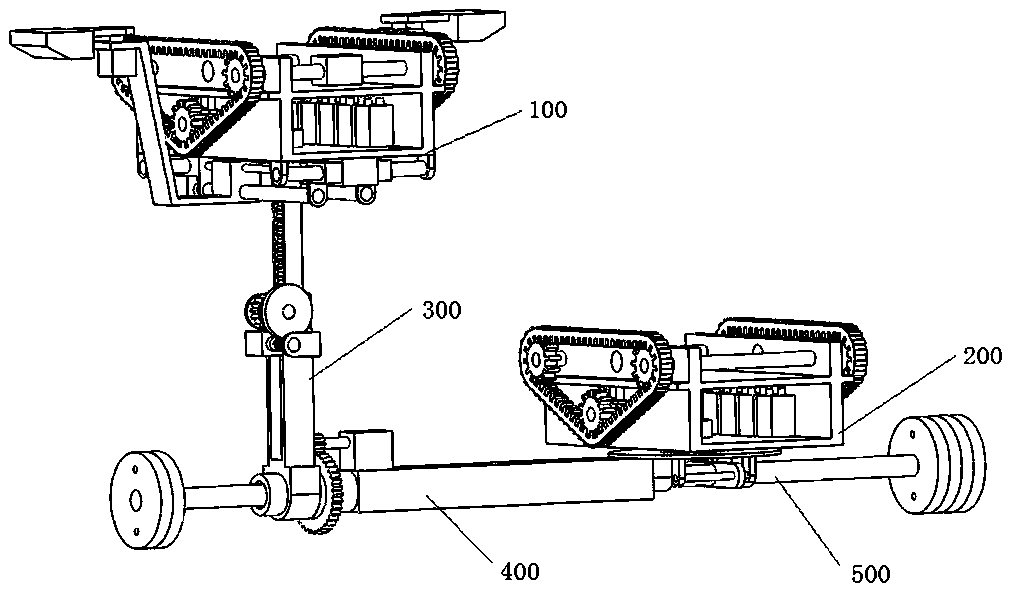

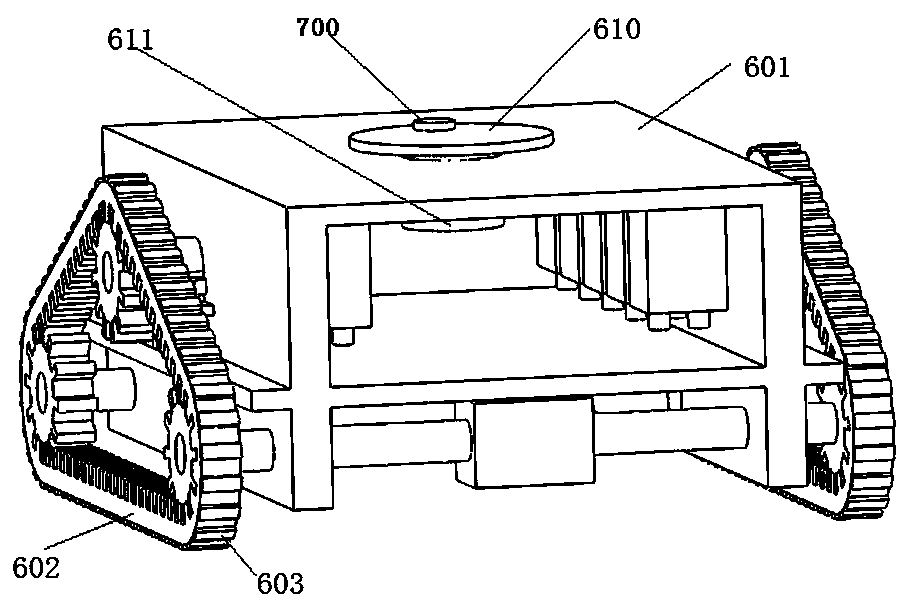

[0033] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

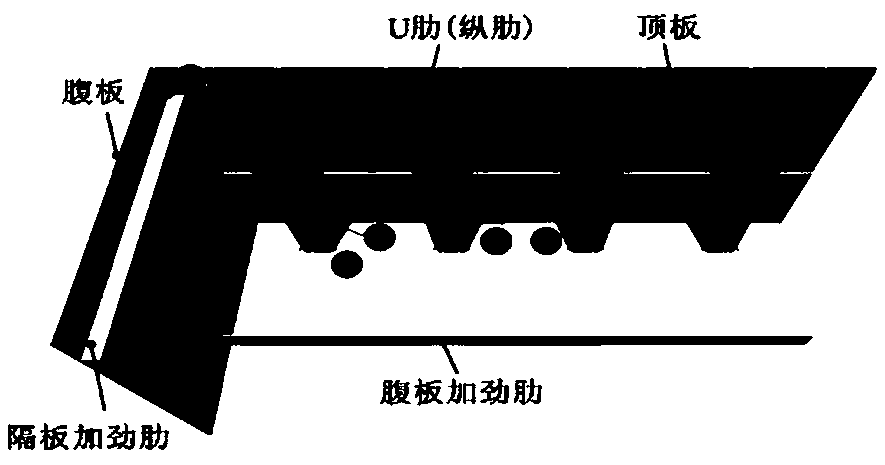

[0034] In the prior art, the detection methods for steel bridge fatigue crack detection mainly include: visual inspection, magnetic particle inspection, penetrant inspection, radiographic inspection and the like. Various detection methods have their own scope of application and technical requirements, especially for complex structures of orthotropic steel bridge decks, it is difficult to complete bridge detection through intelligent and automated means. At present, in order to ensure the safe operation of bridges, it usually takes a lot of manpower to complete the detection of fatigue cracks in steel bridges. After research, we found that ultrasonic non-destructive testing technology can detect surface cracks and internal cracks of componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com