Embedded fixed-type expansion bol

An expansion bolt, fixed technology, applied in the direction of connecting components, pins, mechanical equipment, etc., can solve the problem of unreliable fixing, and achieve the effect of good fixing effect, good fixing reliability, and increasing fixing points.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

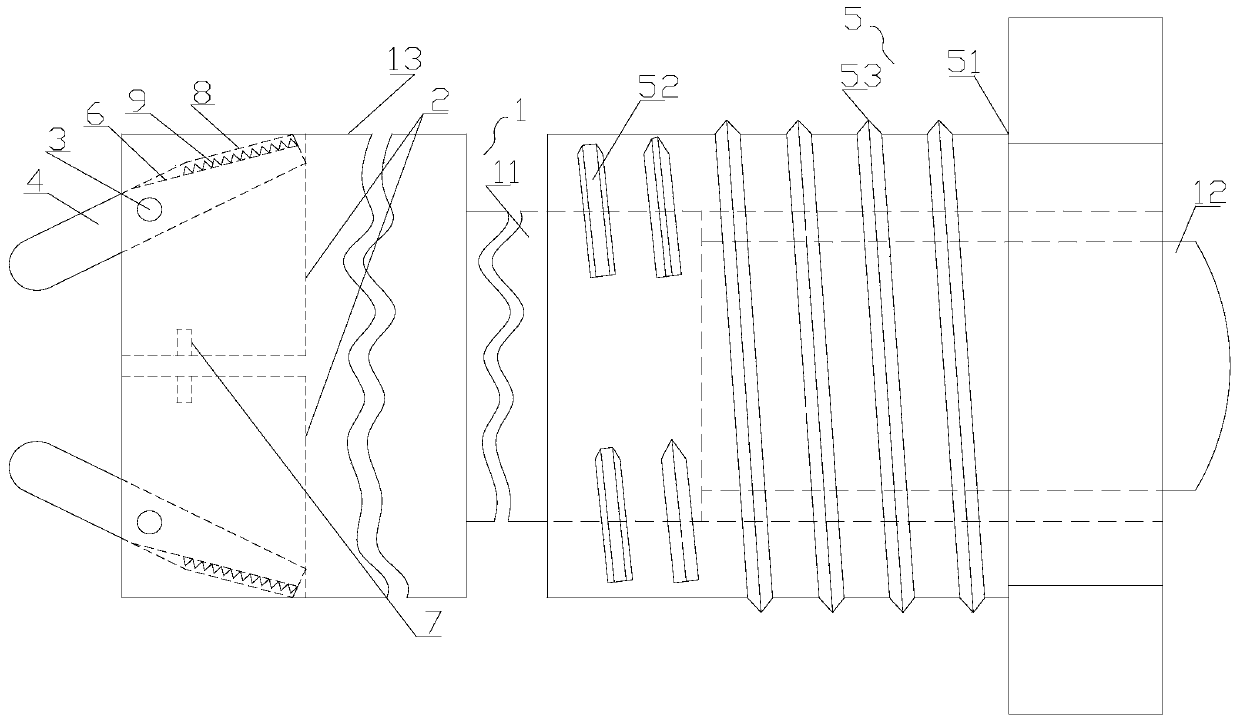

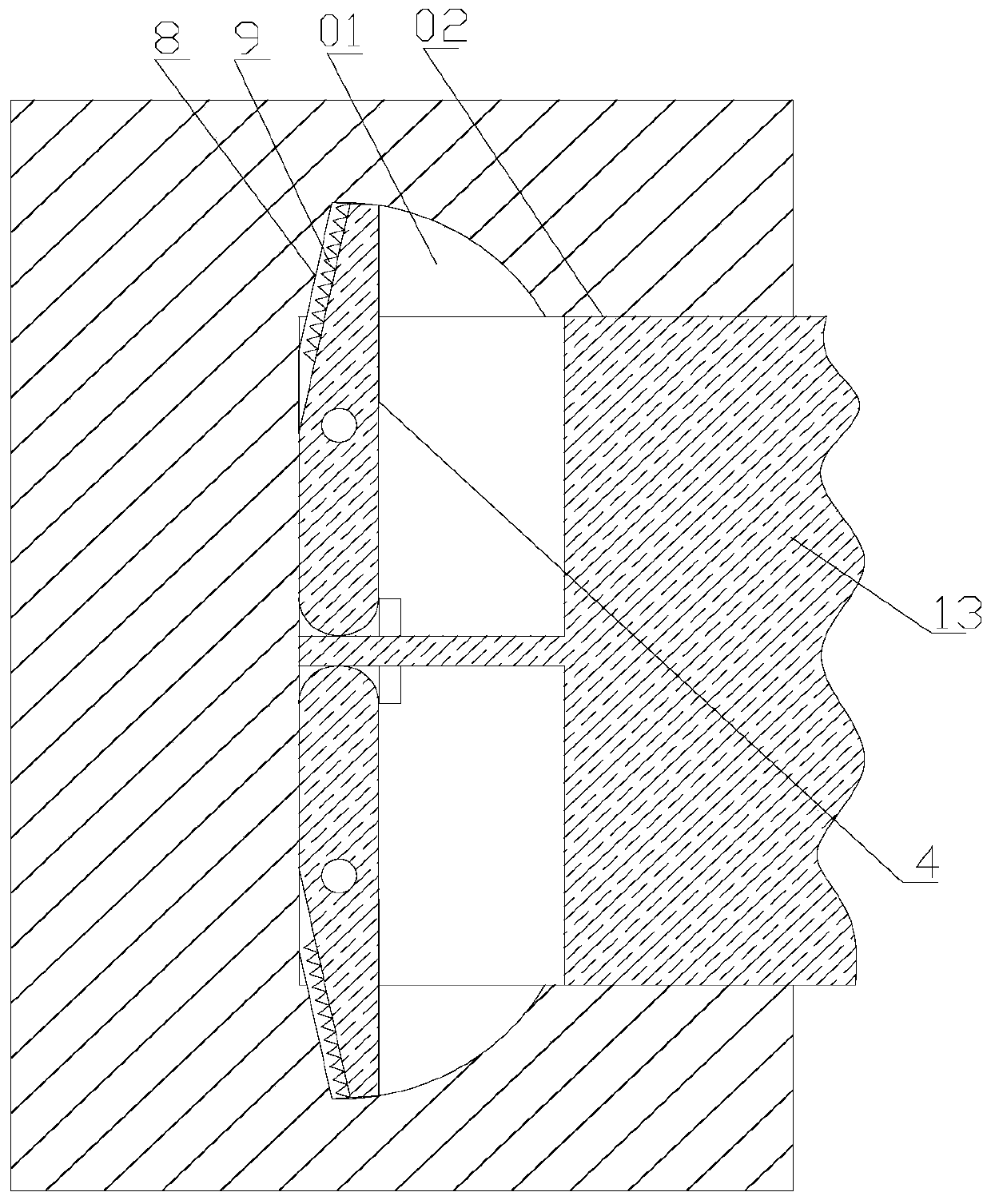

[0017] refer to figure 1 , 2 , an embedded and fixed expansion bolt of the present invention, comprising a screw body 1, a number of opening grooves 2, a number of pin shafts 3, a number of fixing bodies 4 and a screw fixing mechanism 5, and the front end of the screw body 1 is provided with evenly distributed openings Groove 2, the upper end of described open groove 2 runs through the peripheral surface of screw body 1, all is provided with rotatable fixed body 4 through a pin shaft 3 in each described open groove 2, and the lower end of described fixed body 4 Beyond the front end of the opening groove 2, the high end of the fixed body 4 is provided with a cutting portion, the lower end of the opening groove 2 is provided with a stopper 7, and the screw body 1 is provided with a threaded fixing mechanism 5, and the threaded fixing Mechanism 5 comprises a T-shaped nut 51, a tapping portion and a threaded portion 53, and the peripheral surface of the small-diameter section of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com