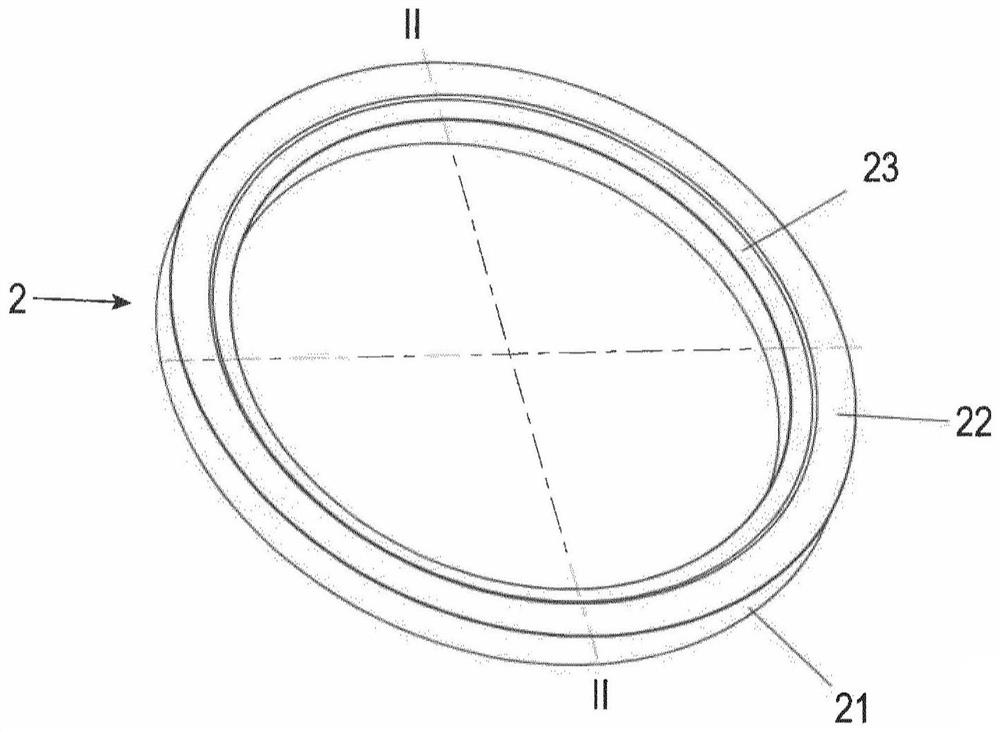

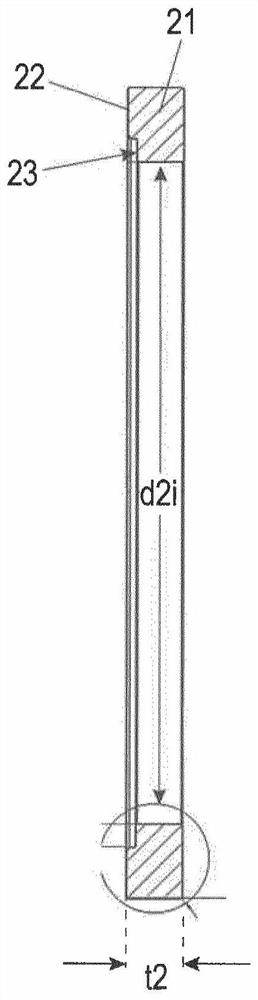

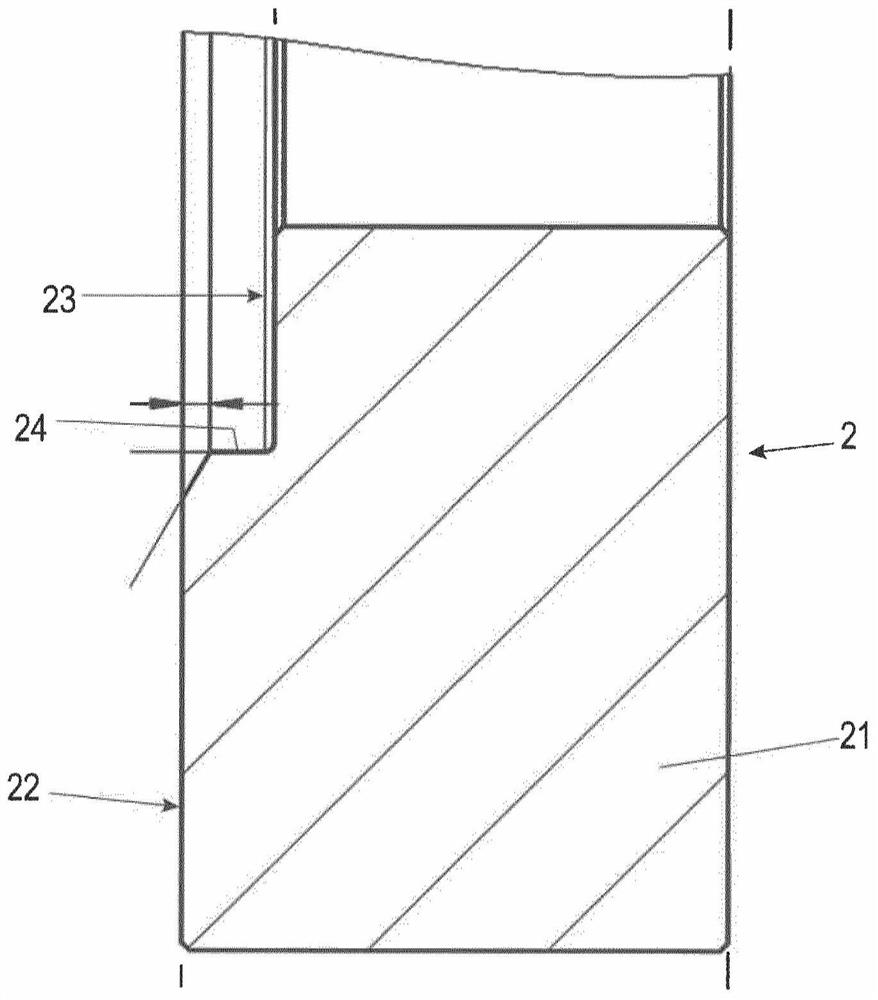

Method for reducing warping of a wheel brake disc for a rail vehicle and device for carrying out the method

A technology for rail vehicles and brake discs, applied in the directions of brake discs, brake components, brakes with pressurized braking surfaces, etc., to reduce inherent stress and improve the repeated assembly rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the following description of the drawings, terms such as upper, lower, left, right, front, rear, etc. only refer to the wheels, brake discs, outer rings, inner rings, upper pressure plates, etc. selected in the corresponding drawings. Exemplary illustrations and locations of . These terms are not to be interpreted as restrictive, which means that these references can change due to different working positions or a mirror-symmetrical design, etc.

[0045] In the method according to the invention, after determining the deviation of the friction surface of the wheel brake disk from a plane defined by the circumferential edges of the friction surface, the friction surface of the wheel brake disk is permanently restored to the surface defined by the circumference of the friction surface. in the plane defined by the edge.

[0046] As "deviation of the friction surface of the wheel brake disc from the plane determined by the circumferential edges of the friction surface", h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com