Ultrahigh strength multiphase steel and method for producing a steel strip from said multiphase steel

A high-strength, multi-phase steel technology, applied in the direction of manufacturing tools, metal rolling, furnaces, etc., can solve the problems of small processing window, different thickness of cold-rolled strip steel, and limited manufacturing flexibility, so as to improve process reliability, Effect of enlarged processing window, uniform mechanical-process characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

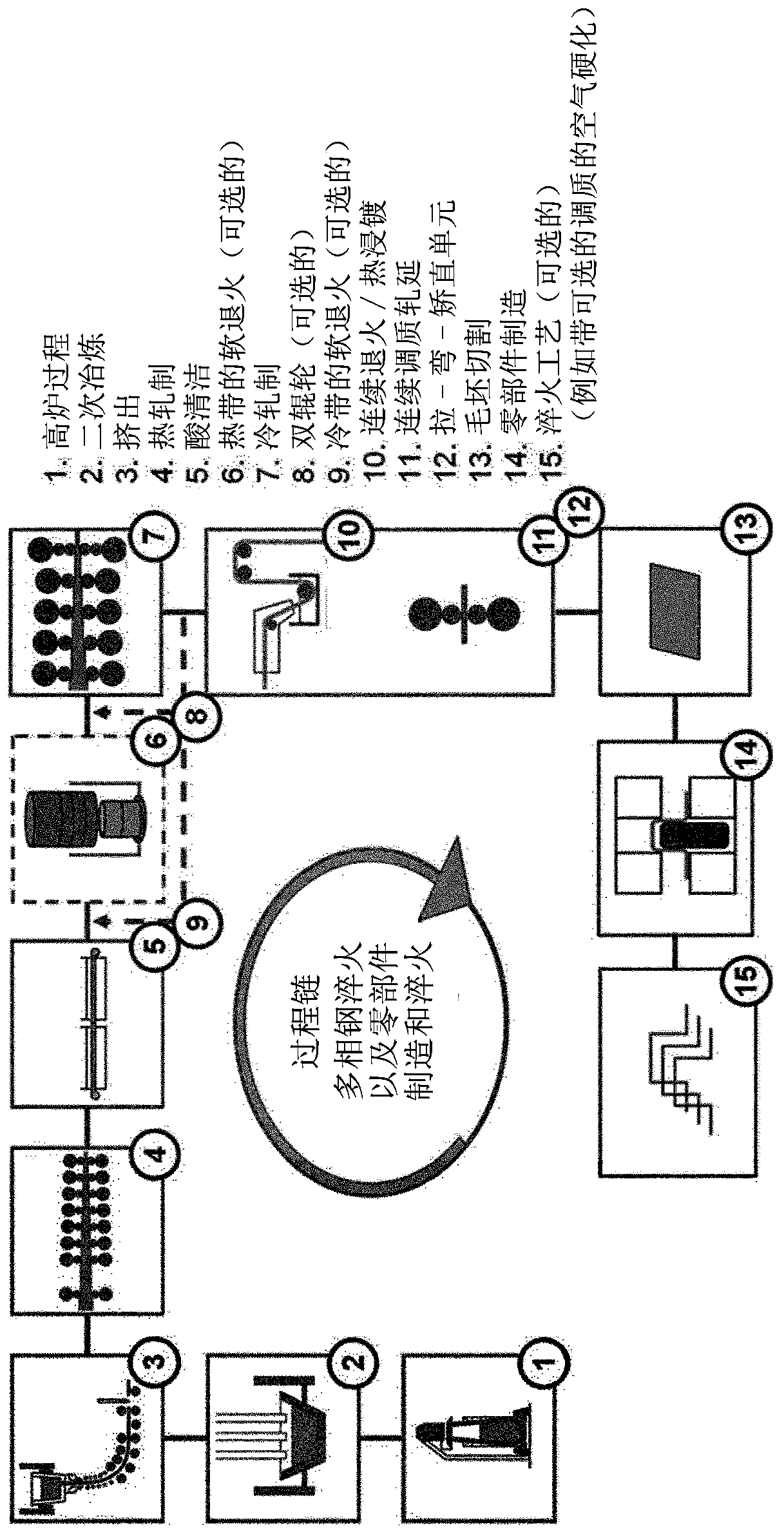

[0291] figure 1 The process chain for producing steel strip from the steel according to the invention is schematically shown. A possible process route in the present invention is shown. The process route is the same for all steels according to the invention until pickling, and then different process routes are carried out depending on the desired result. For example, the pickled hot-rolled strip can be cold-rolled and hot-dip-coated at different rolling ratios after pickling. It is also possible to cold-roll and hot-dip soft-annealed hot-rolled steel strip or soft-annealed cold-rolled steel strip.

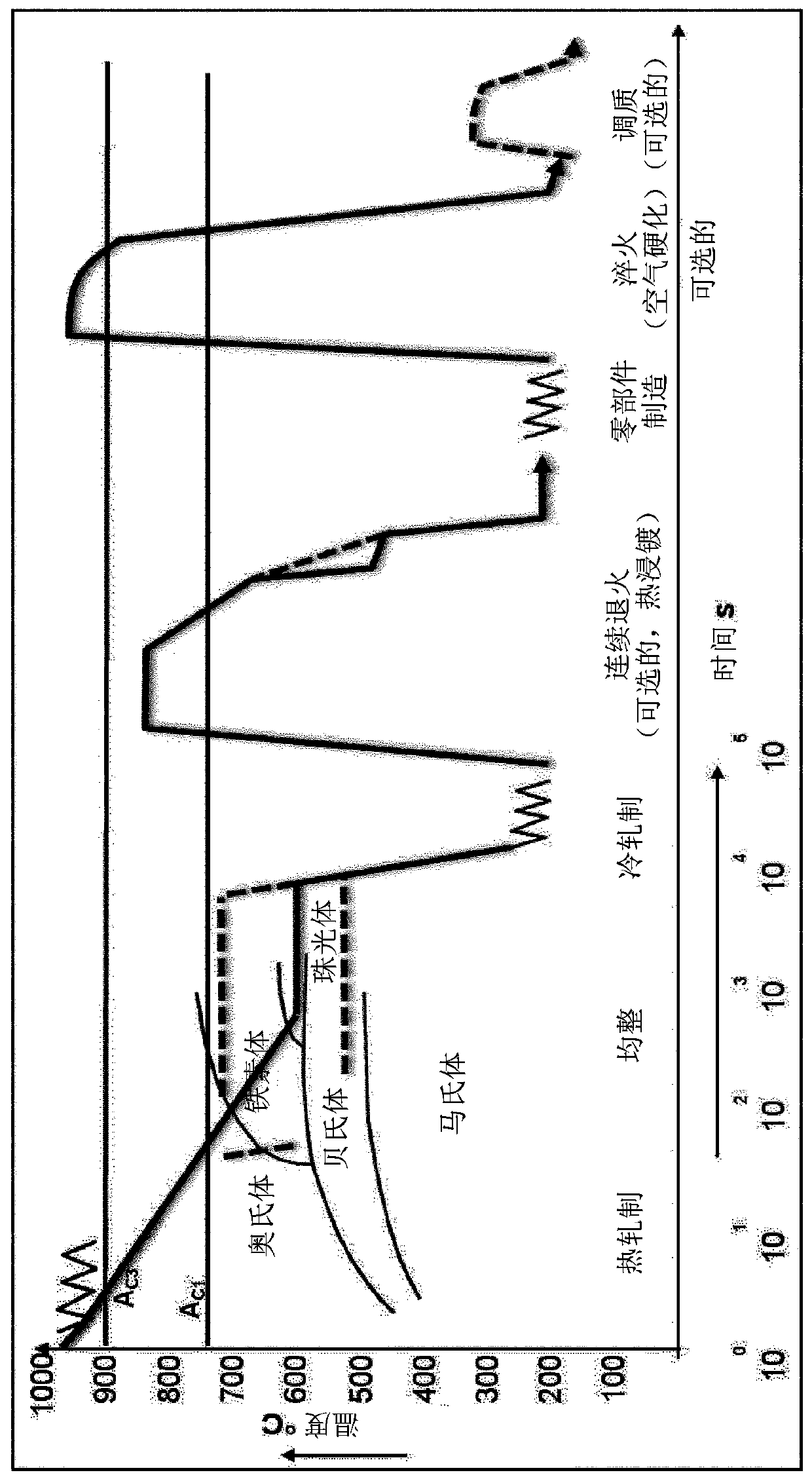

[0292] figure 2 The time-temperature curves for the process steps of hot rolling and continuous annealing of a steel strip composed of an alloy composition according to the invention are shown schematically. Time- and temperature-dependent variants are shown for the hot-rolling process and for the heat treatment after cold-rolling, part production and optional tempering (with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com