Air centrifugal atomizing nozzle

A centrifugal atomization and nozzle technology, used in the field of iron and steel metallurgy, can solve the problems of atomization cone atomization particle size, atomization speed adjustment, small droplet dropping, uneven liquid particles, etc. The effect of deep layer and small hardness gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

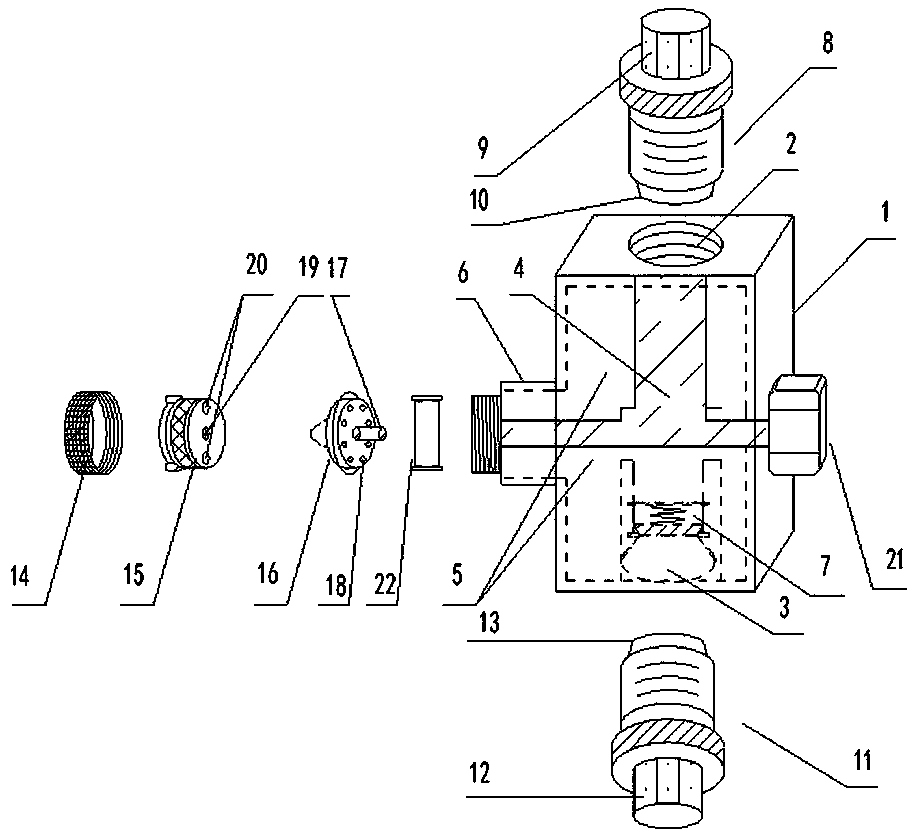

[0020] Such as figure 1 The shown air centrifugal atomizing nozzle includes a nozzle body 1, the nozzle body 1 is a square column, and a liquid inlet 2 and a gas inlet 3 are respectively provided on a pair of parallel surfaces of the nozzle body 1, and the inside of the nozzle body 1 is provided with There are liquid chamber 4 and gas chamber 5 independent of each other, one end of the liquid chamber 4 is connected to the liquid inlet 2, one end of the gas chamber 5 is connected to the gas inlet 3, and the other end of the liquid chamber 4 is connected to the gas chamber 5 The other end of the two is commonly connected to the nozzle seat 6, and a one-way valve 7 controlled by a spring is provided in the gas chamber 5 near the gas inlet; the liquid inlet 2 is provided with a hydraulic insert 8, and the hydraulic insert 8 includes Hydraulic adjustment cap 9 and liquid pipe 10; the gas inlet 3 is provided with a gas insert 11, and the gas insert 11 includes an air pressure adjust...

Embodiment 2

[0022] Referring to Example 1, an optimized design of a conical airflow hole, the central periphery of the fluid nozzle is uniformly distributed with 8 conical airflow holes along the circumferential direction, and the conical airflow holes are offset at an angle of 15° in the same direction, forming a centrifugal airflow.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap