Electro-mechanical brake actuator with internal power electronics unit and energy store

A technology of power electronic devices and actuators, applied in the field of electromechanical brake actuators, which can solve the problems of no longer ensuring the availability of rail vehicles, failure of braking action, disadvantageous functional safety and system availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

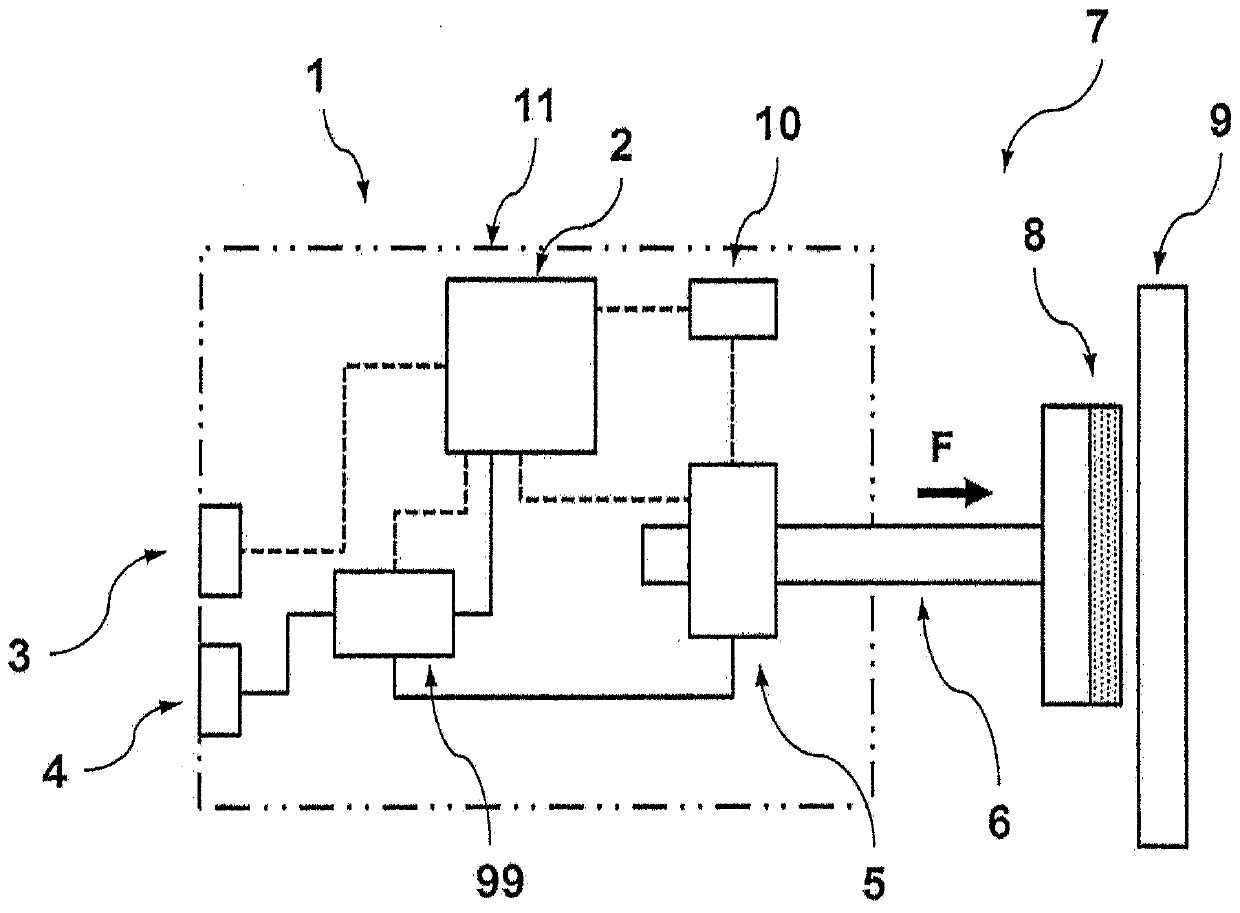

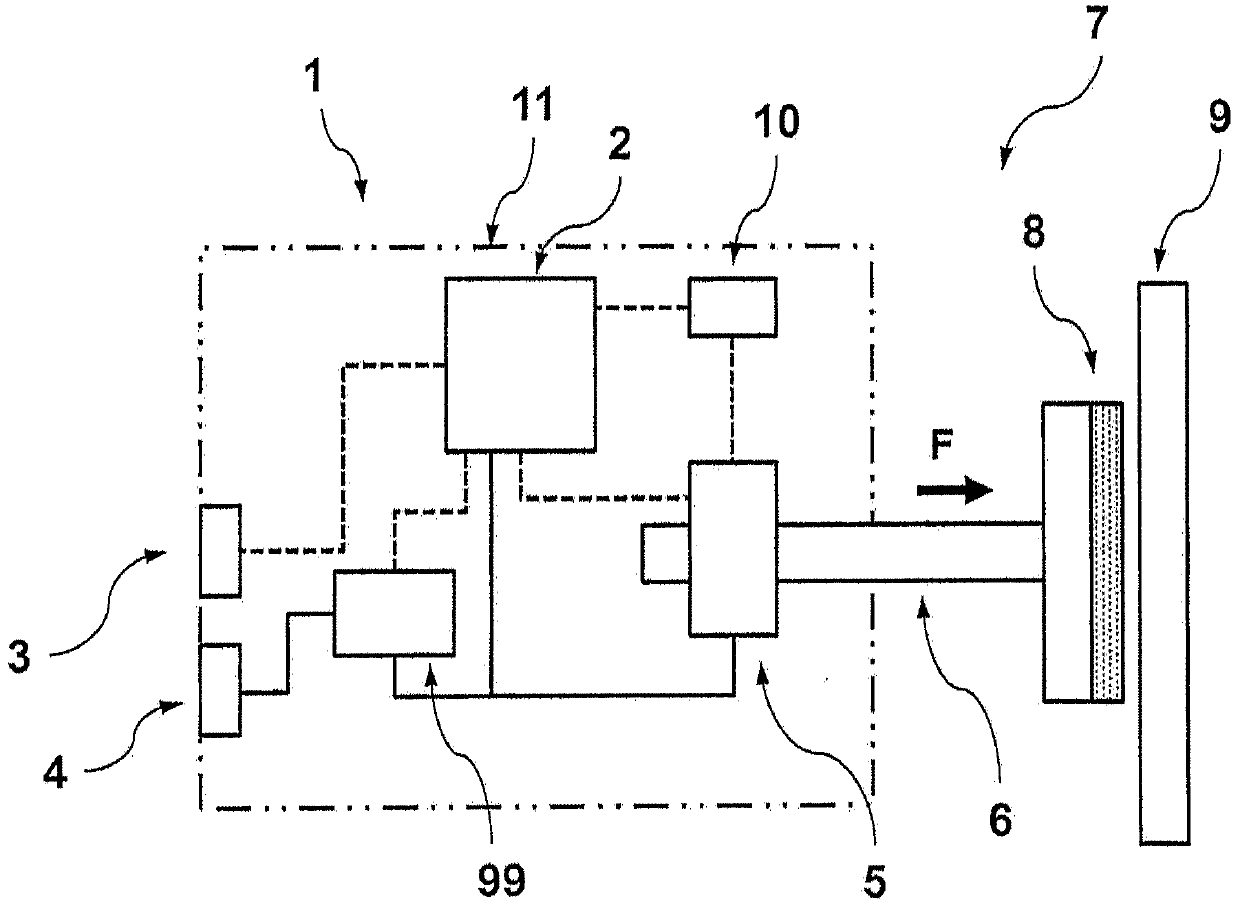

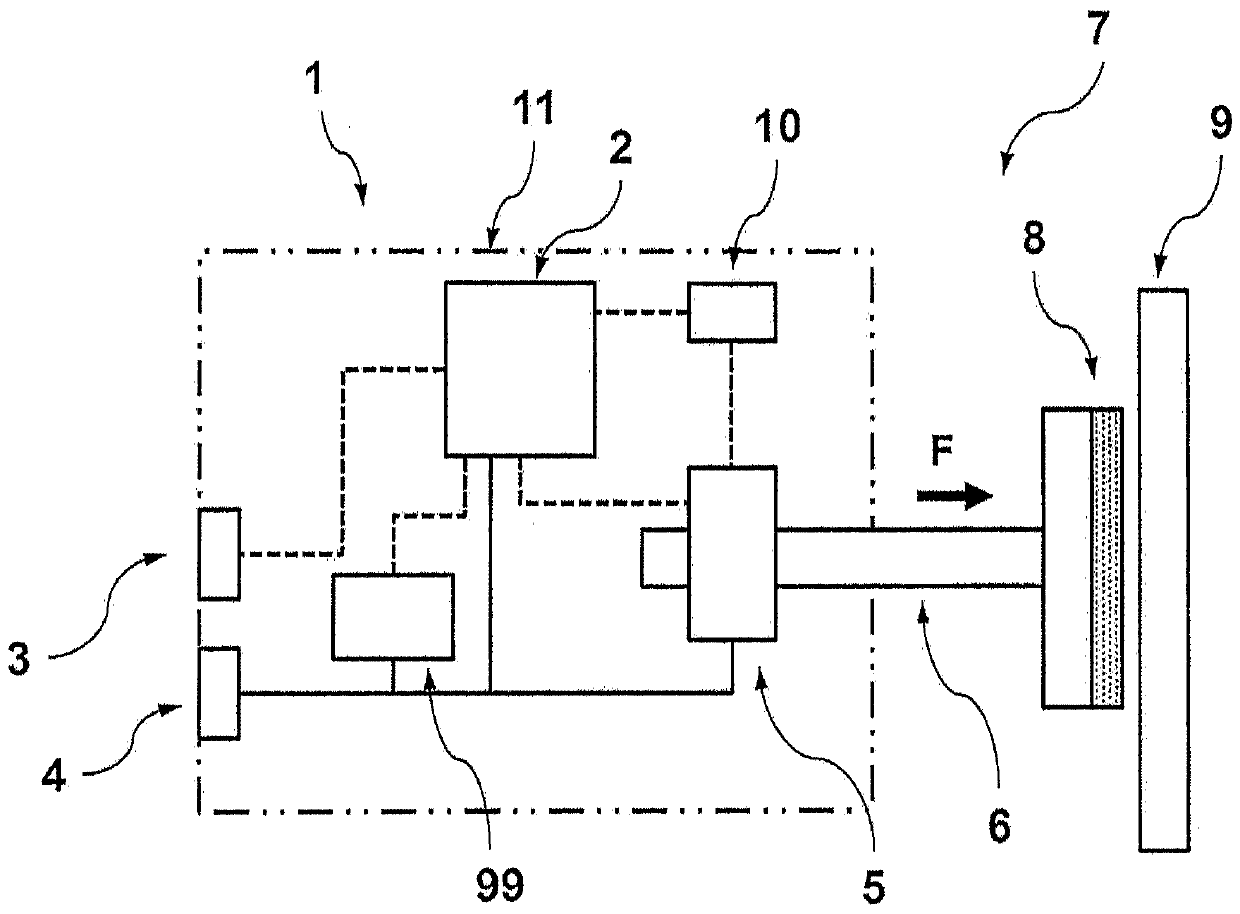

[0020] figure 1 A first embodiment of a brake actuator for a rail vehicle according to the invention is shown. The brake actuator 1 for rail vehicles has: a housing 11; a pressure element 8 configured to be pressed onto a brake disk 9; means 5 for moving the pressure element 8, 6. The device is configured to move the pressing member 8 towards and away from the brake disc 9; the logic unit 2 in the housing 11 is configured to control the pressing member 8 Moving components 5 , 6 ; control interface 3 on housing 11 for connection to a higher-level controller of the rail vehicle located outside the housing; on housing 11 for supplying brake actuator 1 An energy supply interface 4 ; and a pressing force detection unit 10 in the housing 11 for detecting the actual pressing force F of the pressing member 8 on the brake disc 9 . Furthermore, brake actuator 1 has power electronics 99 with an energy store, which is arranged in housing 11 and is assigned to only one brake actuator 1 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com