Method for operating an internal combustion engine having an injection system, injection system designed to carry out a method of this type, and internal combustion engine having an injection system of this type

A technology of internal combustion engine and operation type, which is applied in the direction of charging system, mechanical equipment, machine/engine, etc., and can solve problems such as deterioration of emission characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

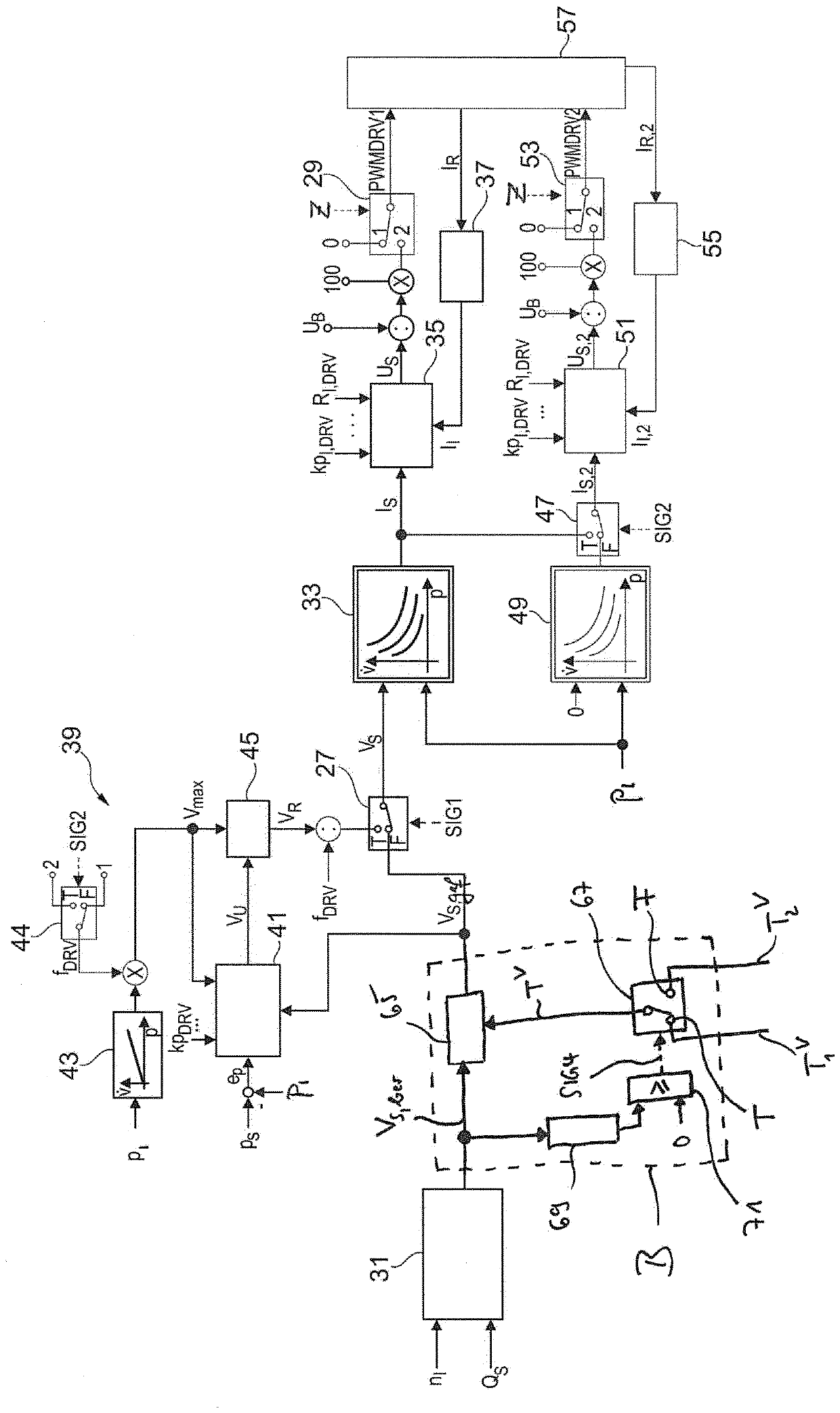

[0036] figure 1 A schematic representation of an exemplary embodiment of an internal combustion engine 1 with an injection system 3 is shown. The injection system is preferably designed as a common rail injection system. The injection system has a low-pressure pump 5 for delivering fuel from a fuel store 7 , an adjustable, low-pressure-side suction throttle 9 for influencing the fuel volume flow through the suction throttle 9 , with A high-pressure pump 11 for delivering fuel under increased pressure into a high-pressure accumulator 13 , a high-pressure accumulator 13 for storing fuel, and a plurality of injectors 15 for injecting fuel into a combustion space 16 of the internal combustion engine 1 . Alternatively, it is possible to implement the injection system 3 with a single accumulator, wherein then, for example, the individual accumulator 17 is integrated into the injector 15 as an additional buffer volume. A first, in particular electrically actuatable, high-pressure-s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap