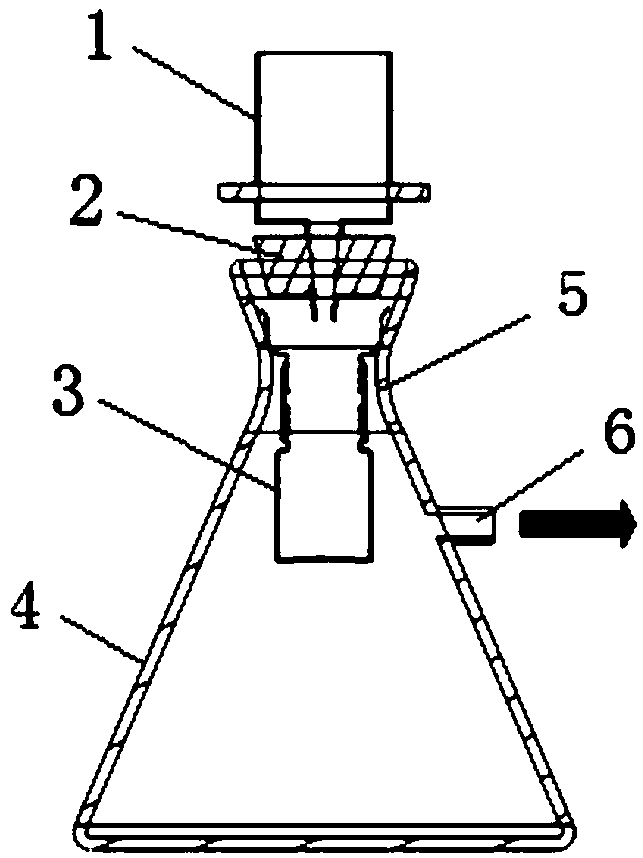

Vacuum sucking filtration sample collector

A technology of sample collection and vacuum filtration, which is applied in the direction of gravity filter, fixed filter element filter, filtration and separation, etc., can solve the problems of cumbersome washing-rinsing operation, unclean washing, incomplete rinsing, etc., and achieve improvement Experimental precision and accuracy, ways to reduce experimental errors, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

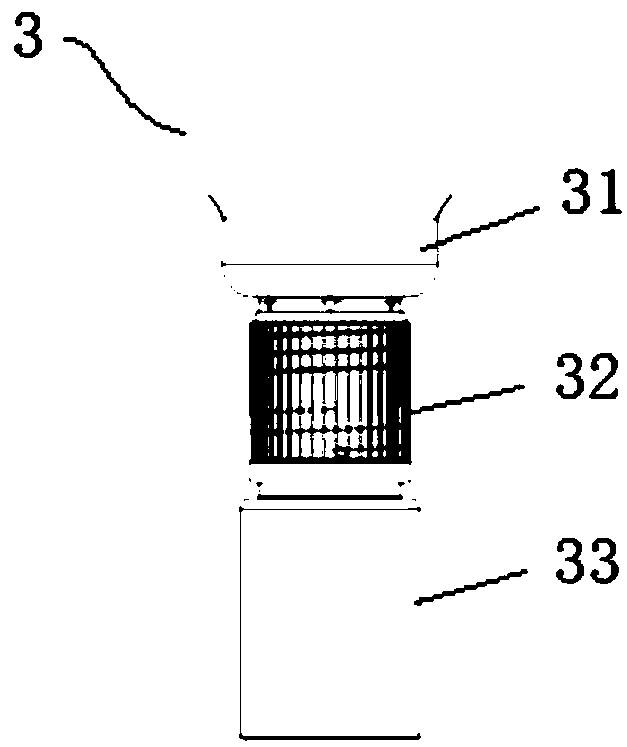

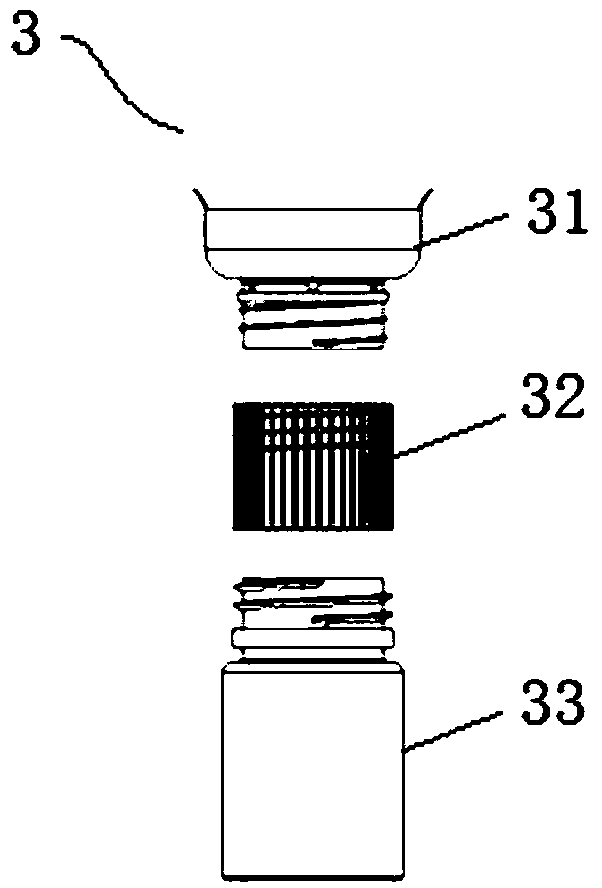

Method used

Image

Examples

experiment example

[0045] Experimental example (comparison of time spent in pumping)

[0046] In this experimental example, using a traditional complete suction operation can be divided into 4 steps: 1. Wash the suction device; 2. Rinse the suction funnel with the sample liquid + rinse the filter bottle with the filtrate. Generally, this step will be Repeat at least 3 times; 3. Extract the raw sample solution; 4. Put the filtered liquid sample into the sample bottle.

[0047] The time taken for each of the above steps is t 1 , t 2 , t 3 , t 4 , then the traditional time t for a complete pumping operation a for

[0048]

[0049] After using the present invention, a complete suction operation can be divided into 3 steps: 1. Wash the suction device; 2. Rinse the suction funnel with the sample stock solution. Generally, this step will be repeated at least 3 times; 3. Pump the sample The stock solution + sample is filled into the sample bottle.

[0050] The time taken for each of the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com