Installation and construction method for building reinforced concrete precast beam

A reinforced concrete and construction method technology, which is applied in the direction of construction, building structure, and building material processing, can solve the problems of low labor force, high technical level and experience requirements for hoisting personnel, and low installation efficiency of prefabricated beams. Sliding, the effect of improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

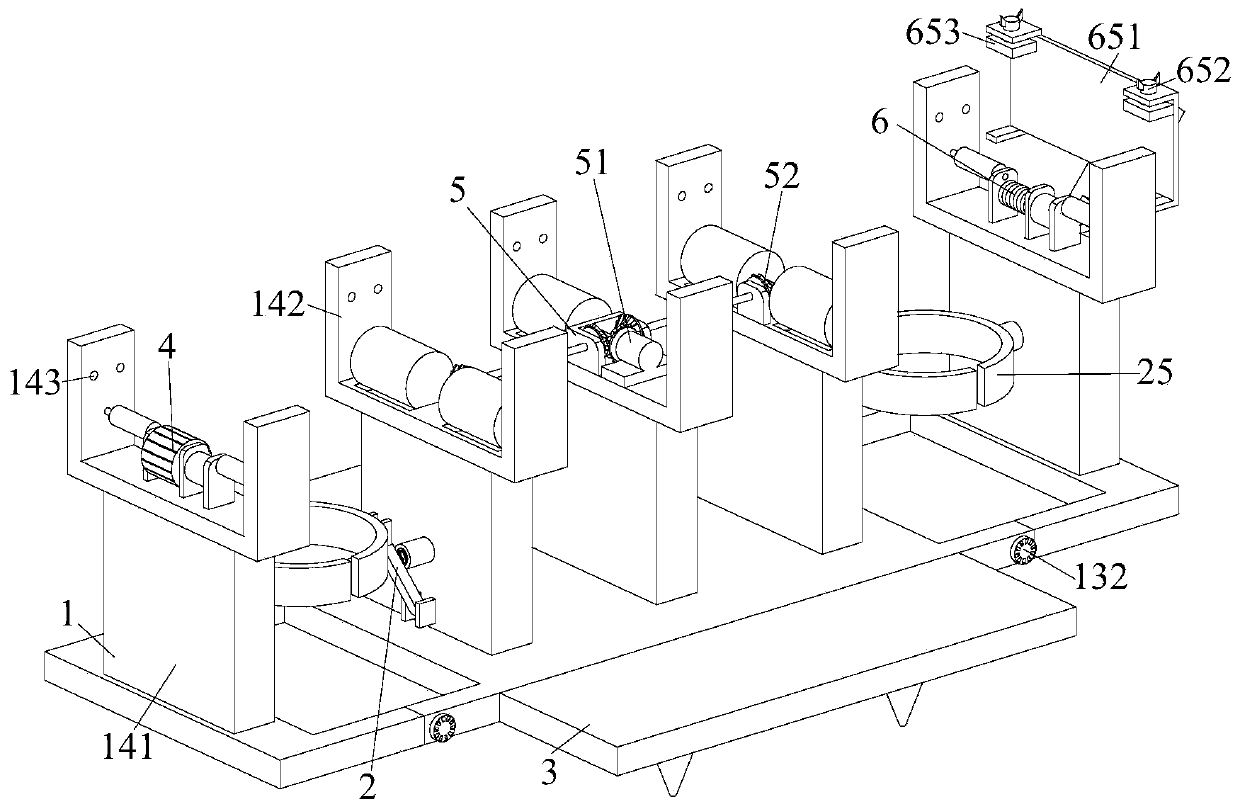

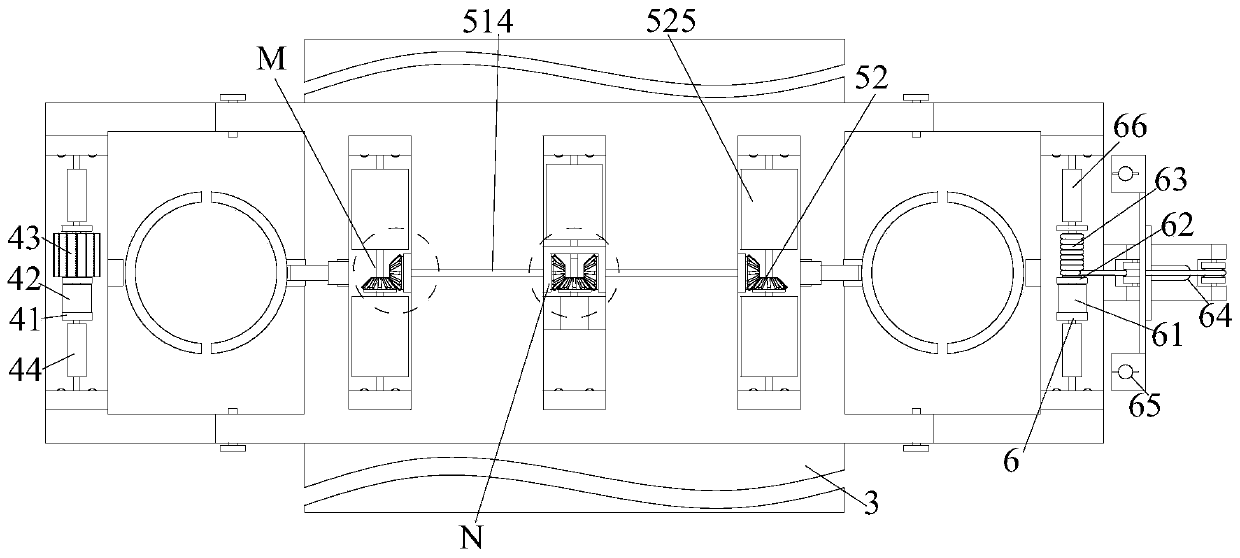

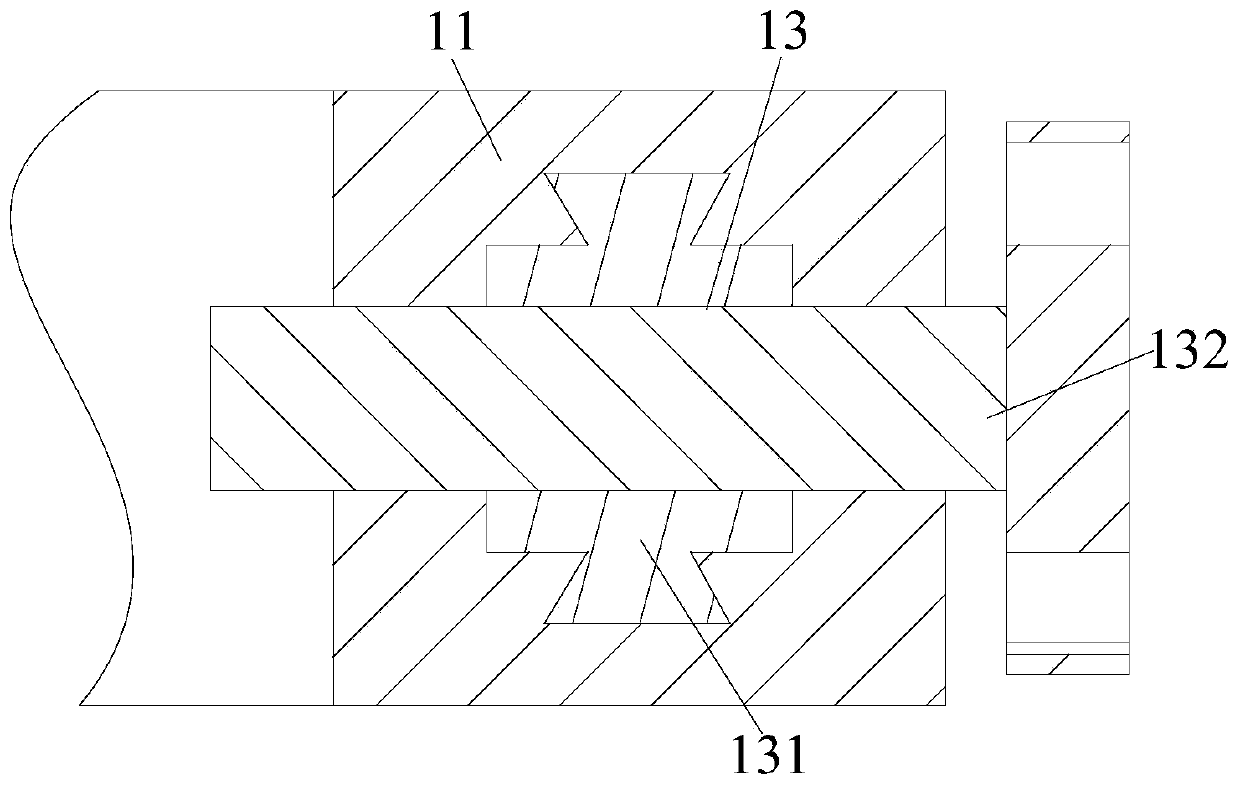

[0041] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 10 , to further elaborate the present invention.

[0042] A construction method for installing reinforced concrete prefabricated beams, the specific installation and construction method is as follows:

[0043] S1. Installation and fixing equipment: Place the middle support plate 11 between the two support columns manually, and connect the end support plate 12 with the middle support plate 11 through the connecting mechanism 13. After the two are connected, pass the compression rod 23 Extrude the semicircular plate 25 with the limit rod 27, thereby locking and fixing the upper end of the device;

[0044] S2. Feeding: After the equipment is installed and fixed, one end of the prefabricated beam is manually placed on the push device 4, and the clamping mechanism 65 is manually fixed on the prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com