Hidden synchronous guide rail of external side-mounted synchronizer

A technology of synchronous device and synchronous guide rail, which is applied to furniture parts, household utensils, drawers, etc., can solve the problems of insufficient smoothness during the push and pull process, high noise of the guide rail, and poor structural stability, so as to achieve convenient installation and later maintenance. The effect of smooth opening and closing of the guide rail and stable supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

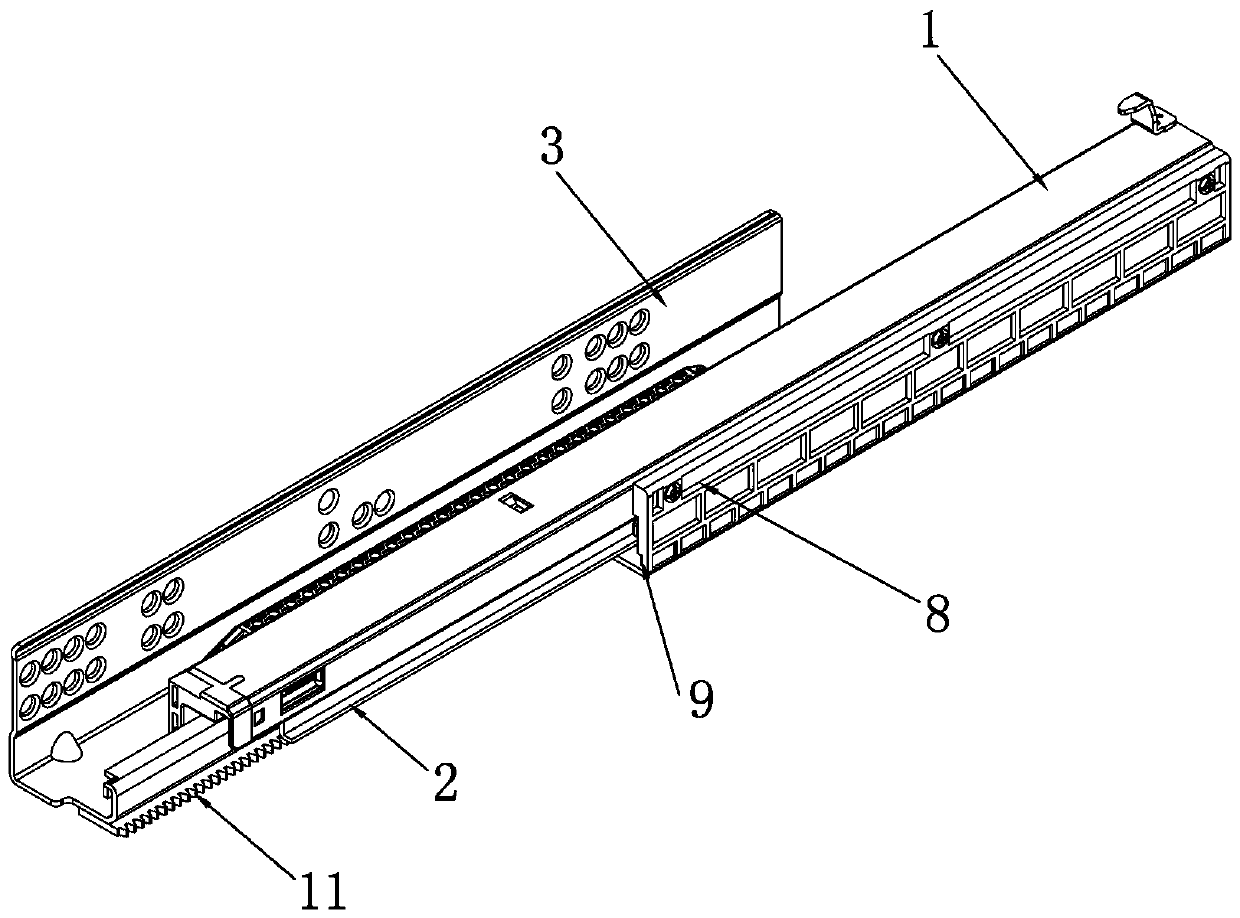

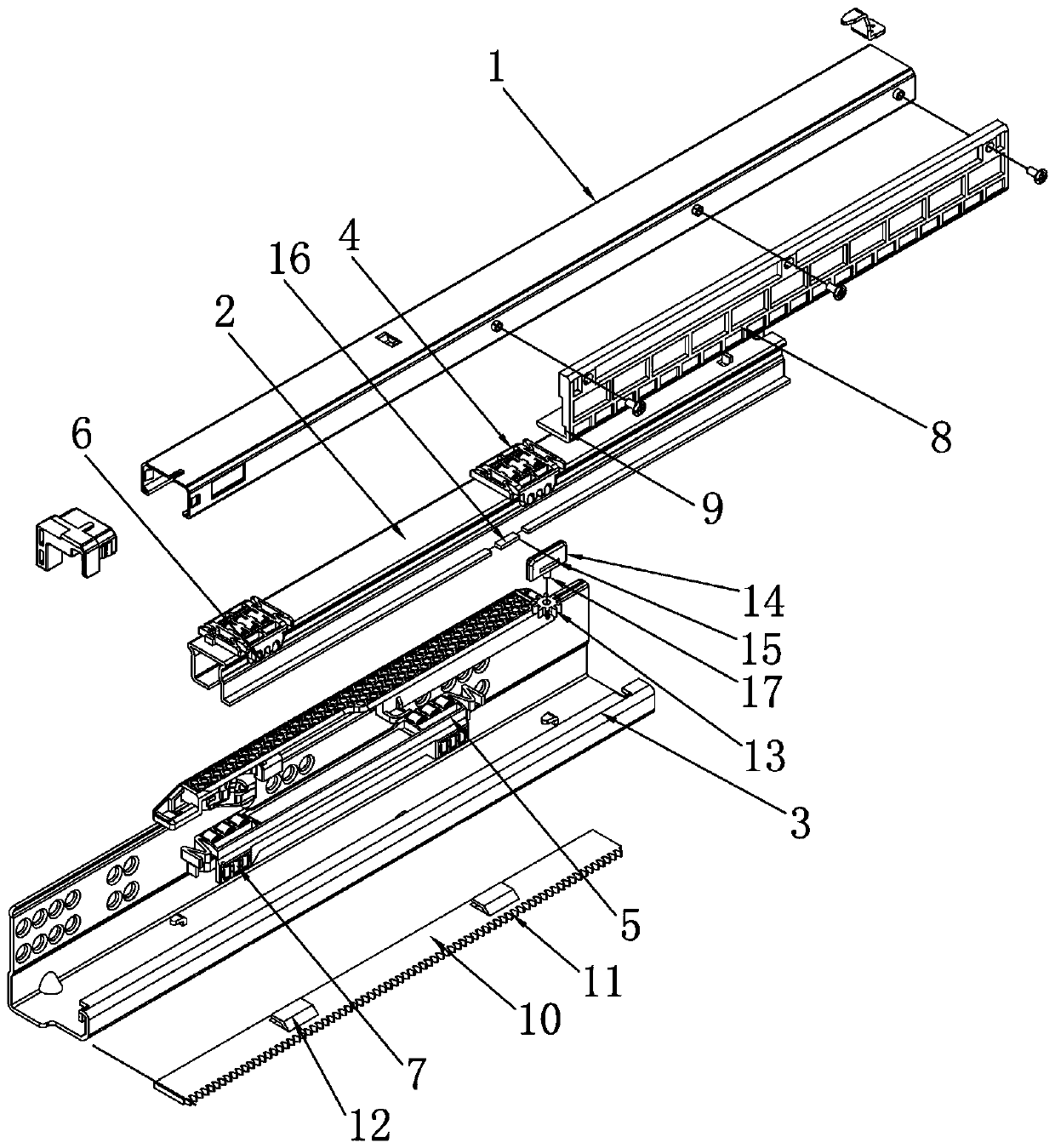

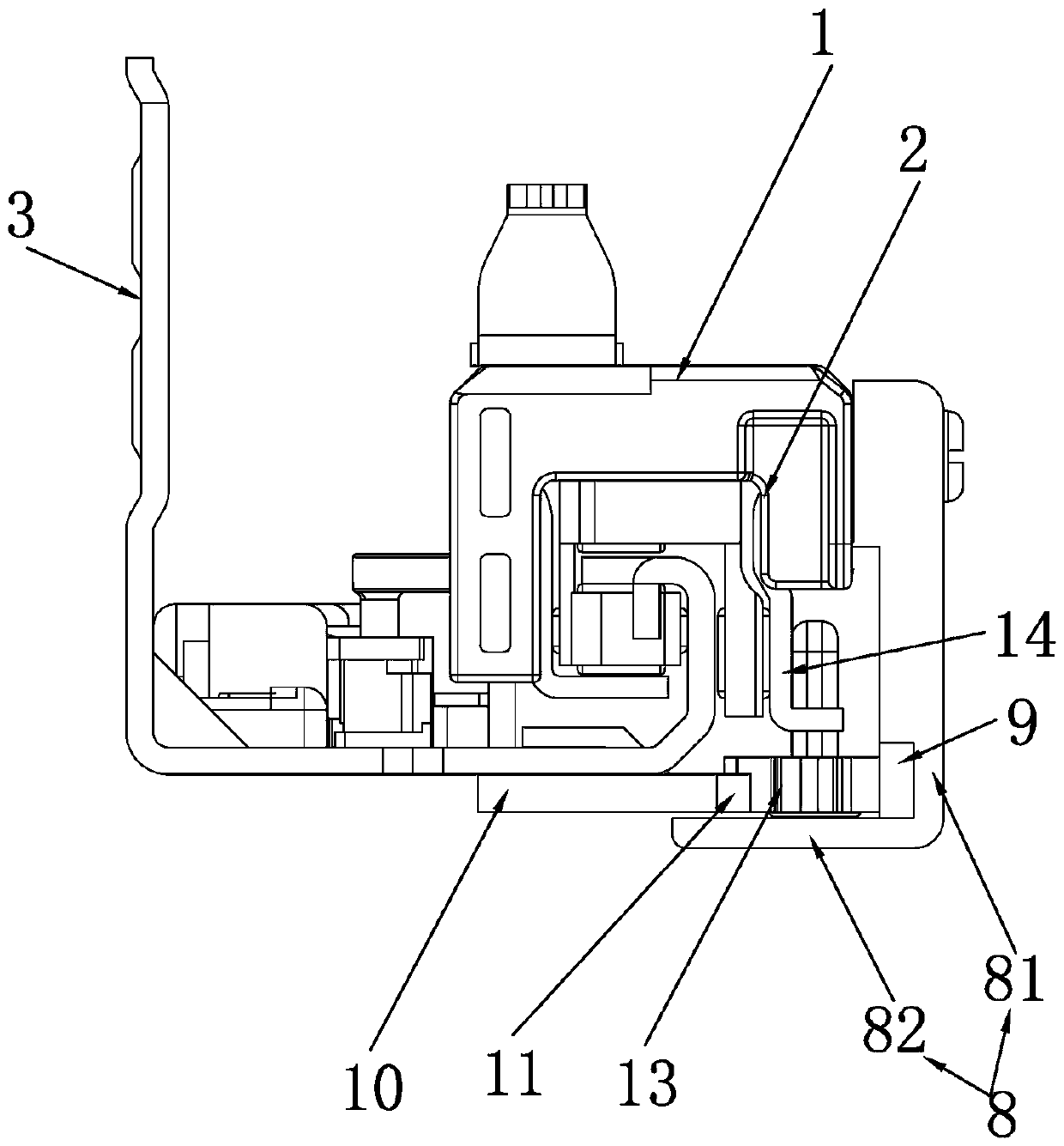

[0021] The present invention will be specifically and further described below in conjunction with the accompanying drawings. A hidden synchronous guide rail with an external side-mounted synchronizing device, which includes an outer rail 1, a middle rail 2 and an inner rail 3 that are sequentially fitted, and an upper bead frame 4 and a middle rail 2 are arranged between the outer rail 1 and the middle rail 2 A lower bead rack 5 is arranged between the inner rail 3, and balls 6 or needles 7 are arranged on the upper bead rack 4 and the lower bead rack 5 to support the slide of the guide rail, and the feature is that the outer rail 1 passes through The upper rack mounting plate 8 is fixedly installed with the upper rack 9, and the tooth direction of the upper rack 9 is set in a horizontal direction. The bottom of the inner rail 3 is installed with the lower rack 11 through the lower rack mounting plate 10, and the middle rail 2 The upper rotary type is equipped with a gear 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com