A driving mechanism of a logistics machine

A technology of driving mechanism and machine table, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., and can solve problems such as long distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in conjunction with accompanying drawing and embodiment:

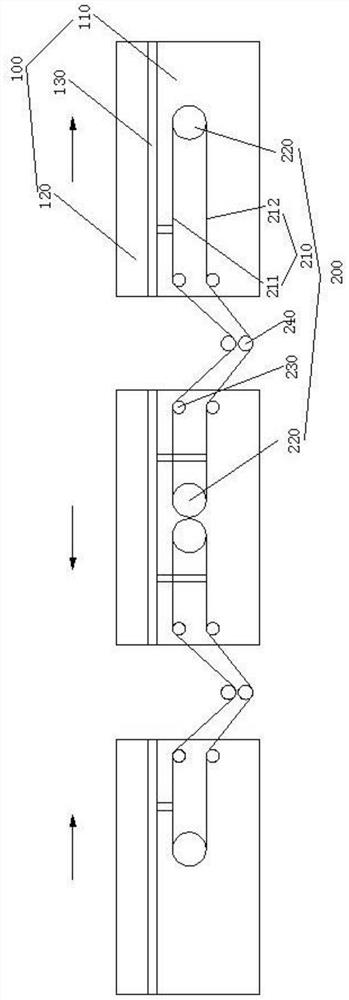

[0018] see figure 1 , as shown in the legend therein, a logistics machine platform includes a plurality of telescopic conveying units 100 arranged at intervals along the first horizontal direction, and each telescopic conveying unit 100 includes a base 110 and a movable The conveying equipment 120 arranged on the base 110 is also provided with a transmission assembly 200 between two adjacent telescopic conveying units 100, the transmission assembly 200 includes a circular transmission member 210, and is installed on two adjacent telescopic conveying units 100 respectively. Two transmission wheels 220 on a base 110, three upper guide wheels 230 and three lower guide wheels 240, the two conveying equipment 120 of two adjacent telescopic conveying units 100 are connected with the upper side of the same circular transmission member 210 respectively. The straight runni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com