Power-off protection method and device

A power-off protection and circuit technology, which is applied in the field of power-off protection methods and devices, can solve problems such as equipment failure to start automatically, energy waste, safety accidents, etc., and achieve the effect of not affecting work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

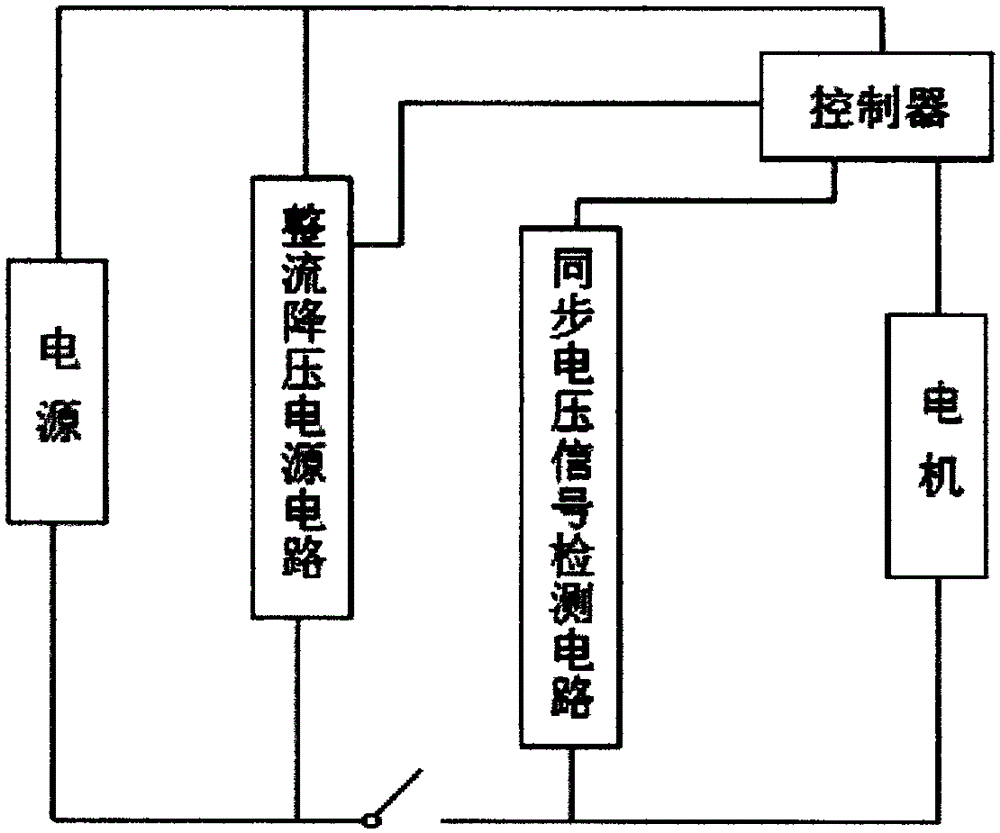

[0036] Such as image 3 and Figure 4 As shown, a power-off protection device includes a controller U1, a thyristor VT, and a rectifying and step-down power supply circuit connected between two ends of the power supply. One end of the power supply is connected to one pole of the motor through a single-pole switch S1, and the other end of the power supply One end is connected to the first anode T1 of the thyristor VT, the second anode T2 of the thyristor VT is connected to the other pole of the motor, the signal input end of the controller U1 is connected to the resistor R3, and the other end of the resistor R3 is connected to the unipolar switch Between S1 and one pole of the motor. The signal input end of the controller U1 is connected to a capacitor C3, and the other end of the capacitor C3 is grounded. A resistor R4 is connected between the signal output end of the controller U1 and the gate G of the thyristor VT. The rectified step-down power supply circuit includes a f...

Embodiment 2

[0039] Such as Figure 5 and Figure 6 As shown, a power-off protection device includes a controller U1, a thyristor VT, and a rectifying and step-down power supply circuit connected between two ends of the power supply. One end of the power supply is connected to one pole of the motor through a single-pole switch S1, and the other end of the power supply One end is connected to the first anode T1 of the thyristor VT, the second anode T2 of the thyristor VT is connected to the other pole of the motor, the signal input end of the controller U1 is connected to a resistor R3, and the other end of the resistor R3 is connected to the thyristor Between the second anode T2 of VT and the motor. The signal input end of the controller U1 is connected to a capacitor C3, and the other end of the capacitor C3 is grounded. A resistor R4 is connected between the signal output end of the controller U1 and the gate G of the thyristor VT. The rectification and step-down circuit includes a fi...

Embodiment 3

[0041] Such as Figure 7 and Figure 8 As shown, a power-off protection device includes a controller U1, a thyristor VT, and a rectifying and step-down power supply circuit connected between two ends of the power supply. In this embodiment, the switch is a bipolar switch K, and one end of the power supply It is connected to the motor through a bipolar switch K, the other end of the power supply is connected to the first anode T1 of the thyristor VT, and the second anode T2 of the thyristor VT is connected to the motor through a bipolar switch K. The synchronous voltage signal detection circuit comprises a first synchronous voltage signal detection circuit and a second synchronous voltage signal detection circuit, the bipolar switch K is located between the first synchronous voltage signal detection circuit and the second synchronous voltage signal detection circuit, and the first synchronous voltage signal The detection circuit includes a resistor R3. One end of the resistor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com