Multi-column strip vertical packing machine

A vertical packaging machine, multi-row technology, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of high cost, complicated structure, and no detection of whether the material is put into the packaging bag, etc., to improve production efficiency. , The effect of reducing costs and reducing the number of manual product picking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

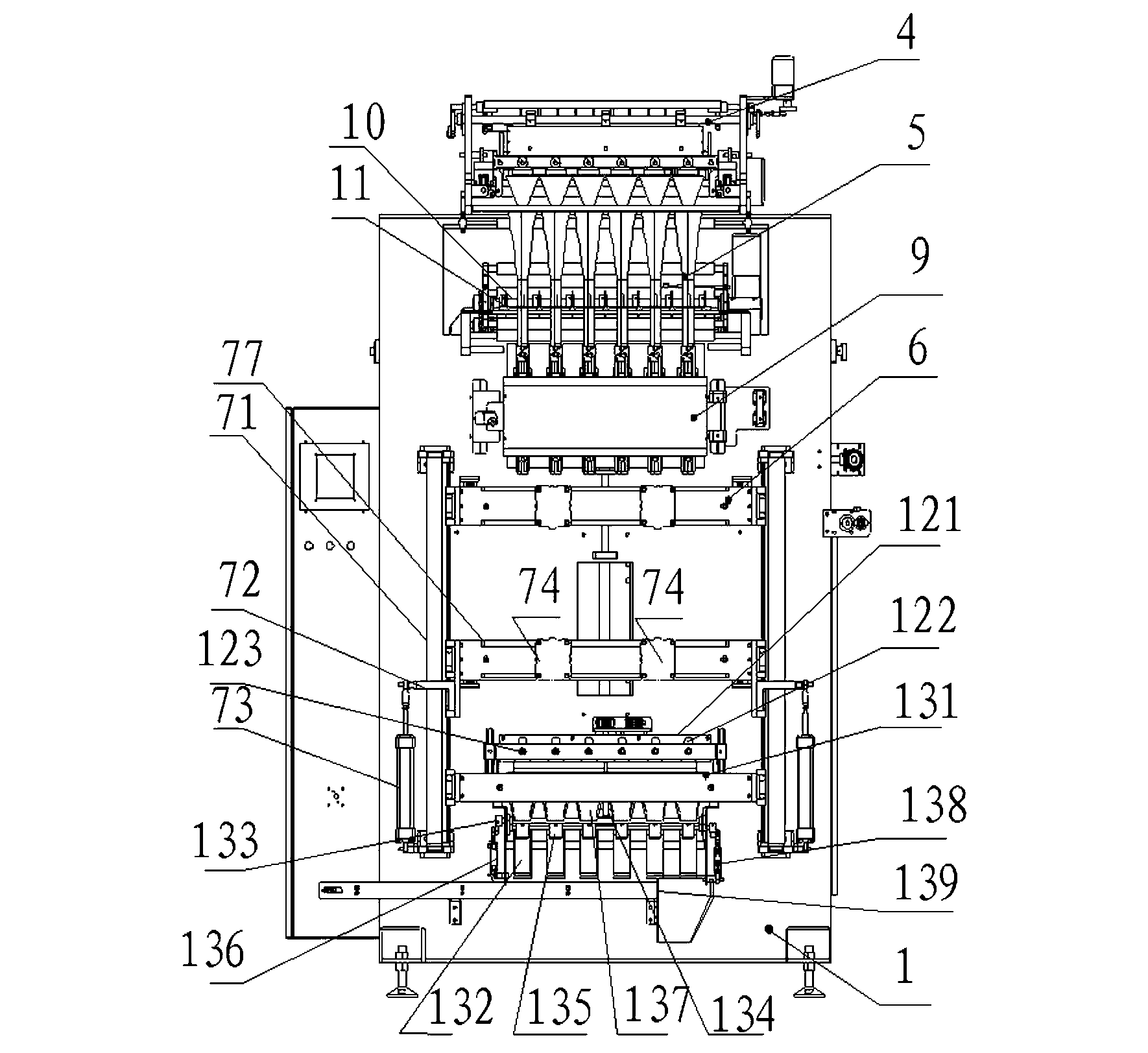

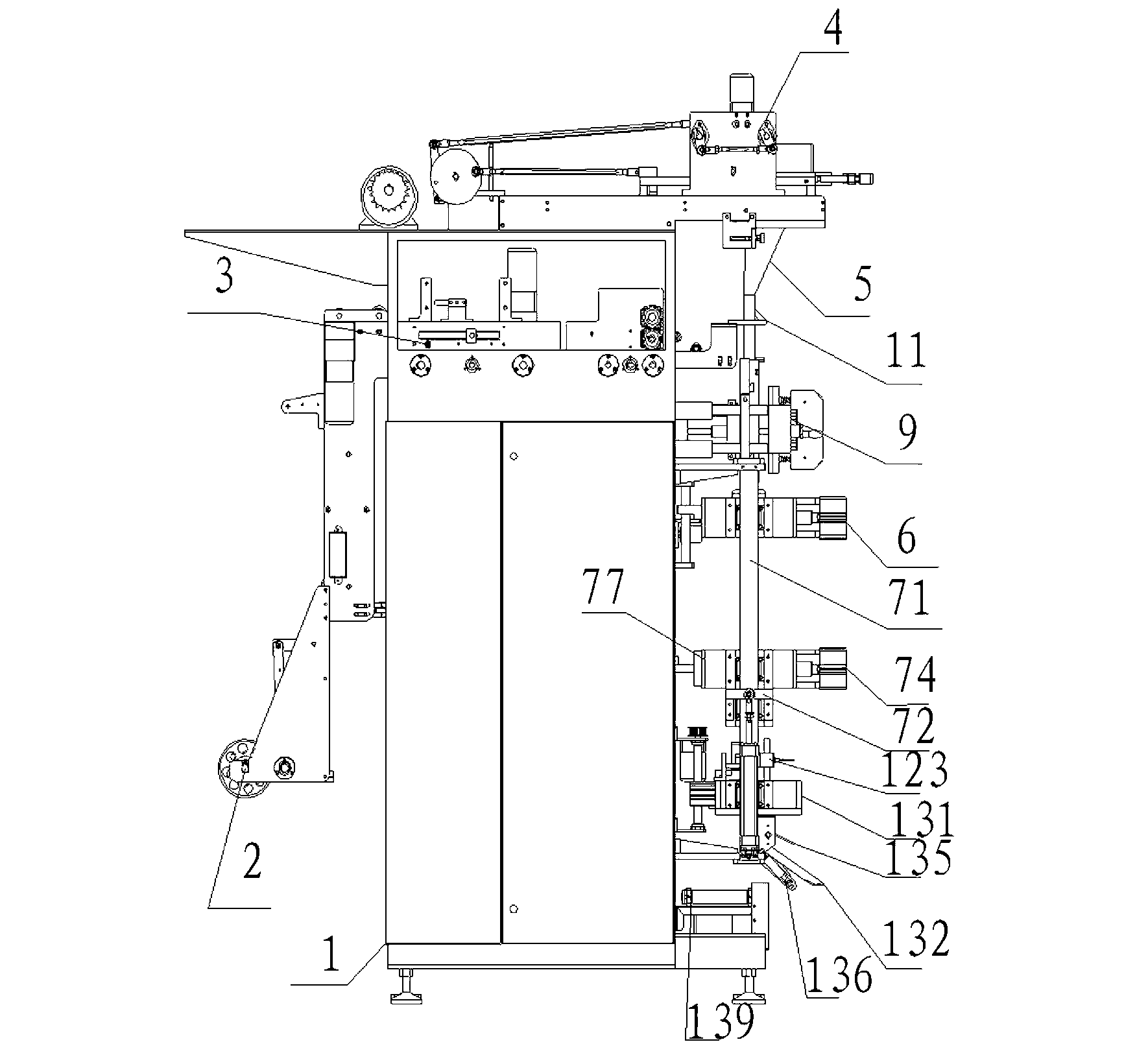

[0017] Such as Figure 1-Figure 2 As shown, the present invention comprises frame 1, film feeding device 2, film walking device 3, feed hopper 4, some collar forming devices 5, horizontal sealing device 6, some vertical sealing devices 9 and a cutting device 10, so Described film feeding device 2 is located at frame 1 rear; Described film walking device 3 is located at frame 1 top; The film outlet end of film moving device 3 is provided with some collar forming devices 5 that are arranged side by side; Described collar forming A feed hopper 4 is provided above the device 5, and a slitting device 10 is provided below the collar forming device 5; a longitudinal sealing device 9 is provided below each cutter 11 of the slitting device 10, and a vertical sealing device 9 is arranged below the vertical sealing device 9. A horizontal sealing device 6 is provided, and the horizontal sealing device 6 includes two upright guide rails 71, two sliders 72 matched with the guide rails...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com