Ink gun for printer and its manufacturing method

A manufacturing method and printing device technology, applied in printing and other fields, can solve the problems of affecting the ink supply of the inkjet head, the inkjet work is not smooth, the flow rate cannot be quite stable, etc., and achieve the effect of smooth ink supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Detailed description of the preferred embodiment

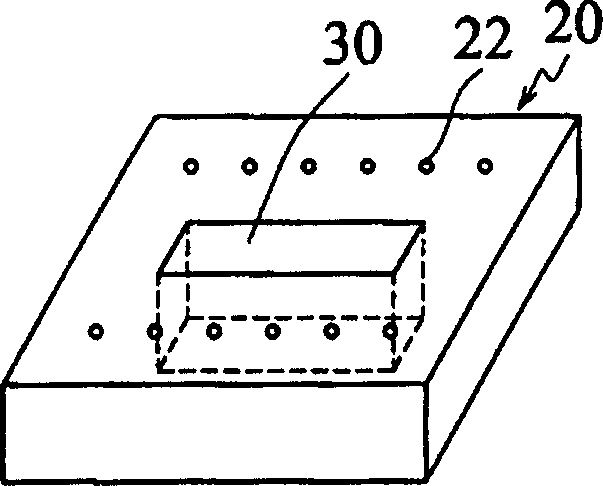

[0020] see figure 2 , the present invention is used for the inkjet head of printing device and its manufacturing method, and this inkjet head comprises a substrate 20 of silicon dioxide, is provided with a plurality of inkjet elements above the substrate 20, and this embodiment is heating element 22; A nozzle layer (not shown in the figure) is arranged on the top of the substrate 20, and a spray hole (not shown in the figure) is formed on it relative to each heating element 22 of the substrate 20. This is the structure of a general inkjet head, and is not shown here. A detailed description. An ink channel 30 is formed in the center of the substrate 20, through which the ink flows to the heating element 22, so that the inkjet head performs ink jetting.

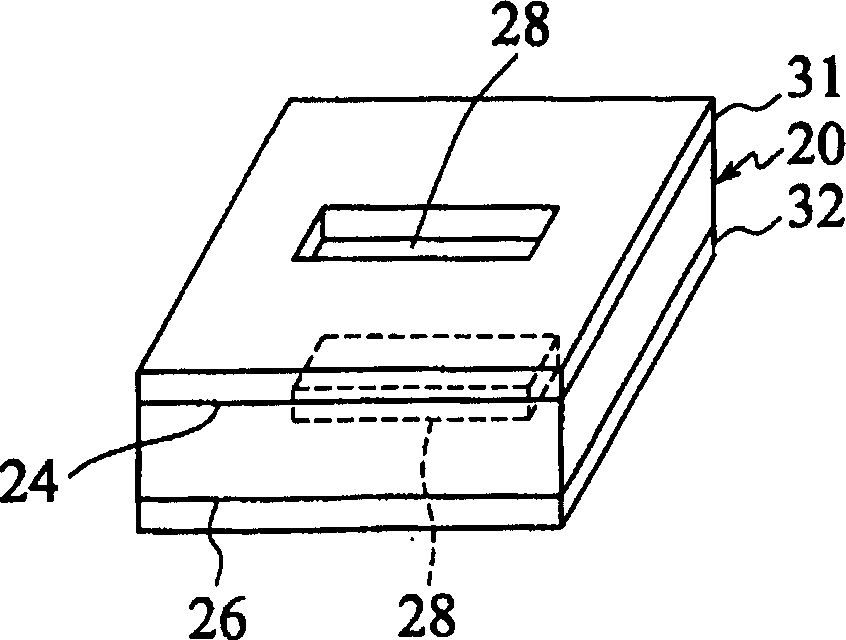

[0021] see image 3 , the present invention is used for the inkjet head of printing device and manufacturing method thereof, at first provides a substrate 20 that is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com