Structure of ink gun and ink jet printing system

An inkjet head and ink technology, applied in printing and other directions, can solve the problems of high laser perforation cost, increase the cost of heating chips, and increase the chance of breaking, and achieve the effect of improving product quality rate, production quality rate, and work performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

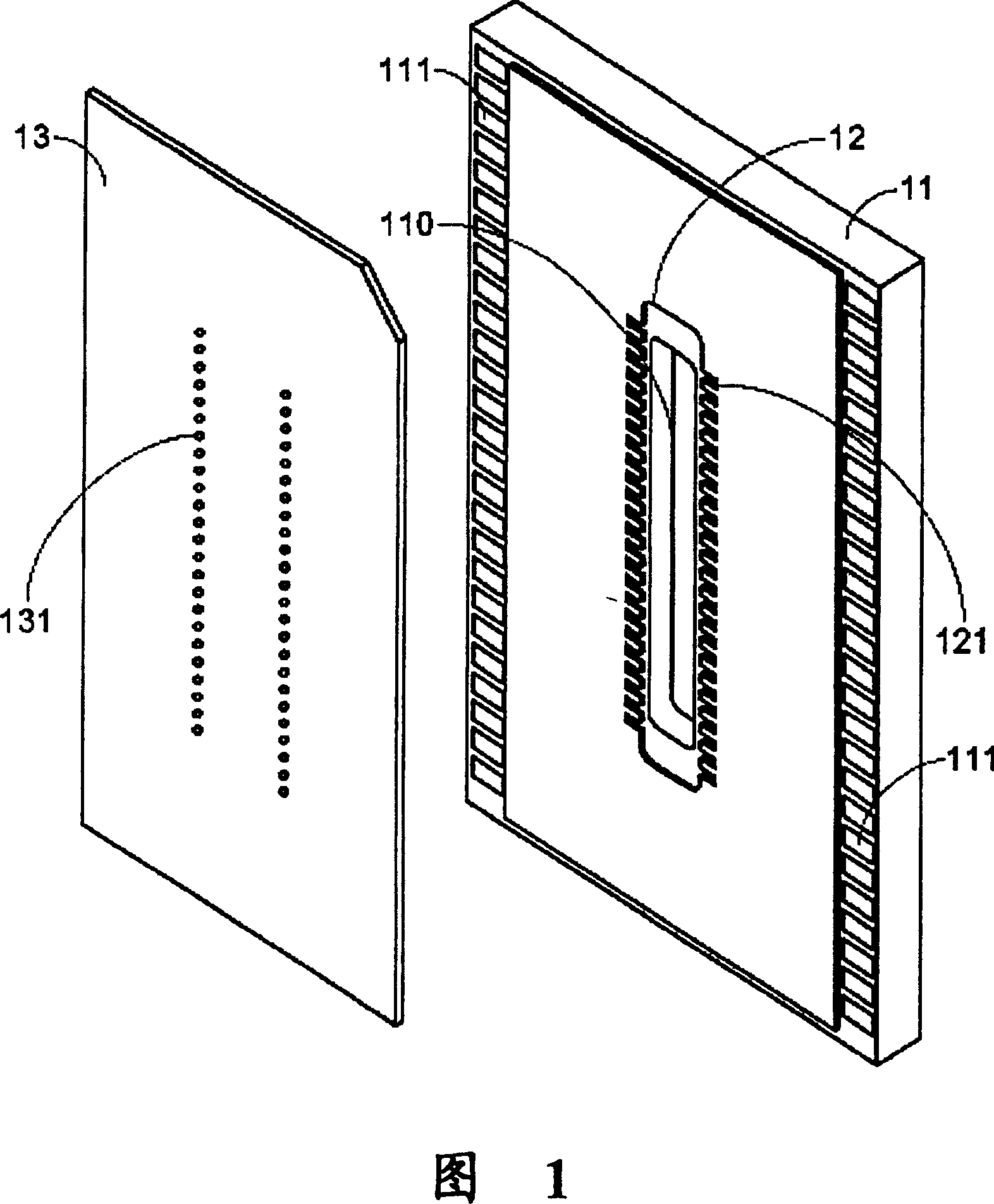

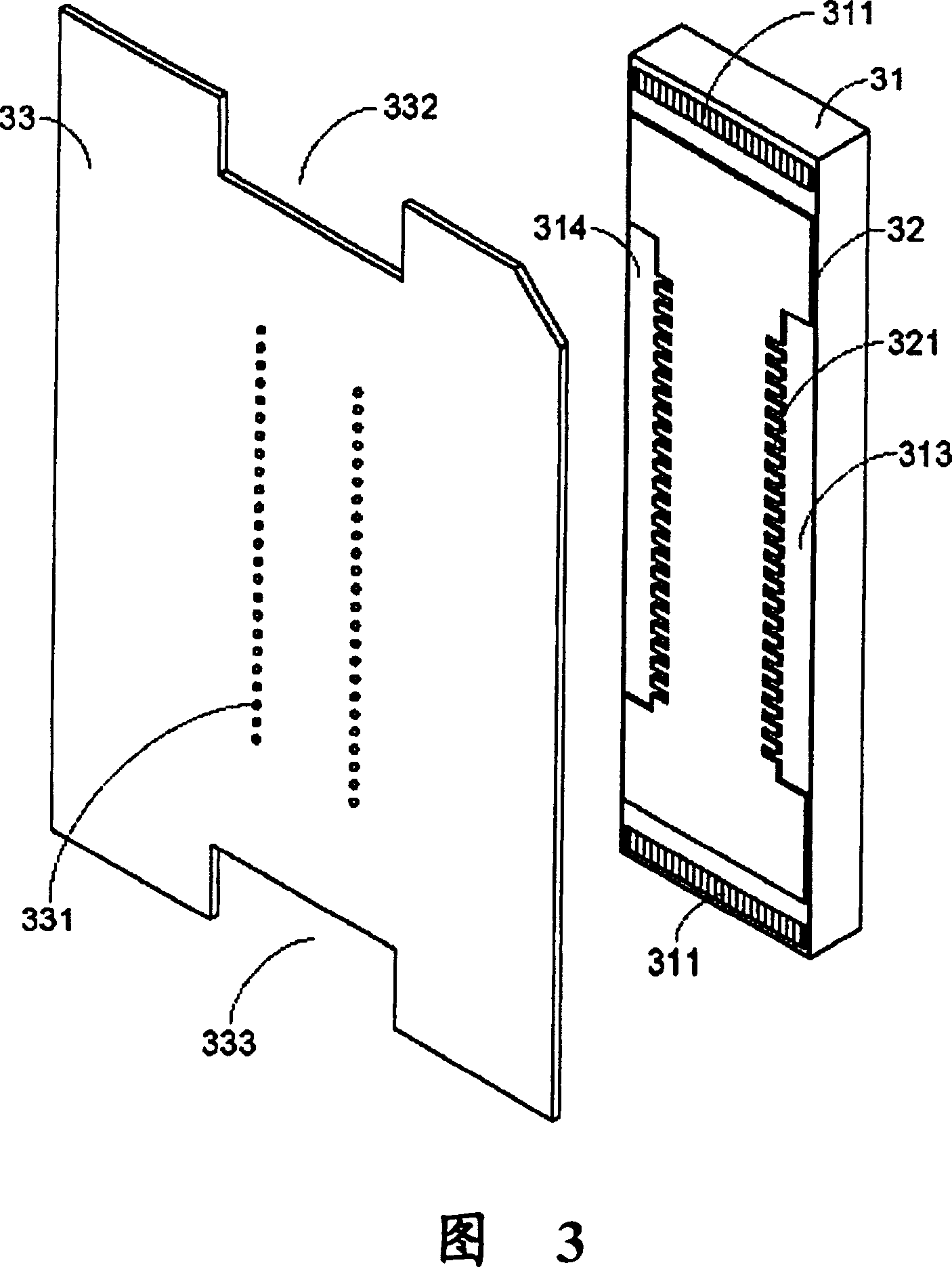

[0041] Please see Fig. 3, the structure of the inkjet head according to the first preferred embodiment of the present invention is mainly composed of a heater IC (heater IC) 31, a barrier layer (barrier layer) 32 and a nozzle plate (nozzle plate) 33 . The heating chip 31 is substantially rectangular, with welding pads 311 on its upper and lower edges. The barrier layer 32 is formed on the heating chip 31 , and together with the heating chip 31 forms an ink supply channel and a plurality of ink cavities 321 . The heating chip 31 is provided with a heating resistor (not shown) corresponding to each ink cavity 321 . The orifice sheet 33 is substantially in the shape of an “H”, and a plurality of orifices 331 corresponding to the ink cavity 321 are disposed above it.

[0042] The feature of the present invention is that when the barrier layer 32 is formed on the heating chip 31, the heating chips 313 and 314 on the left and right sides will be exposed (that is, the barrier layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com