Ink storage material of ink box

A technology of ink storage and cartridges, which is applied in printing and other fields, can solve the problems of not being able to make full use of the space of ink supply cartridges, different printing colors, and unsmooth ink supply, and achieve easy control of the process, simple processing methods, The effect of smooth ink supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

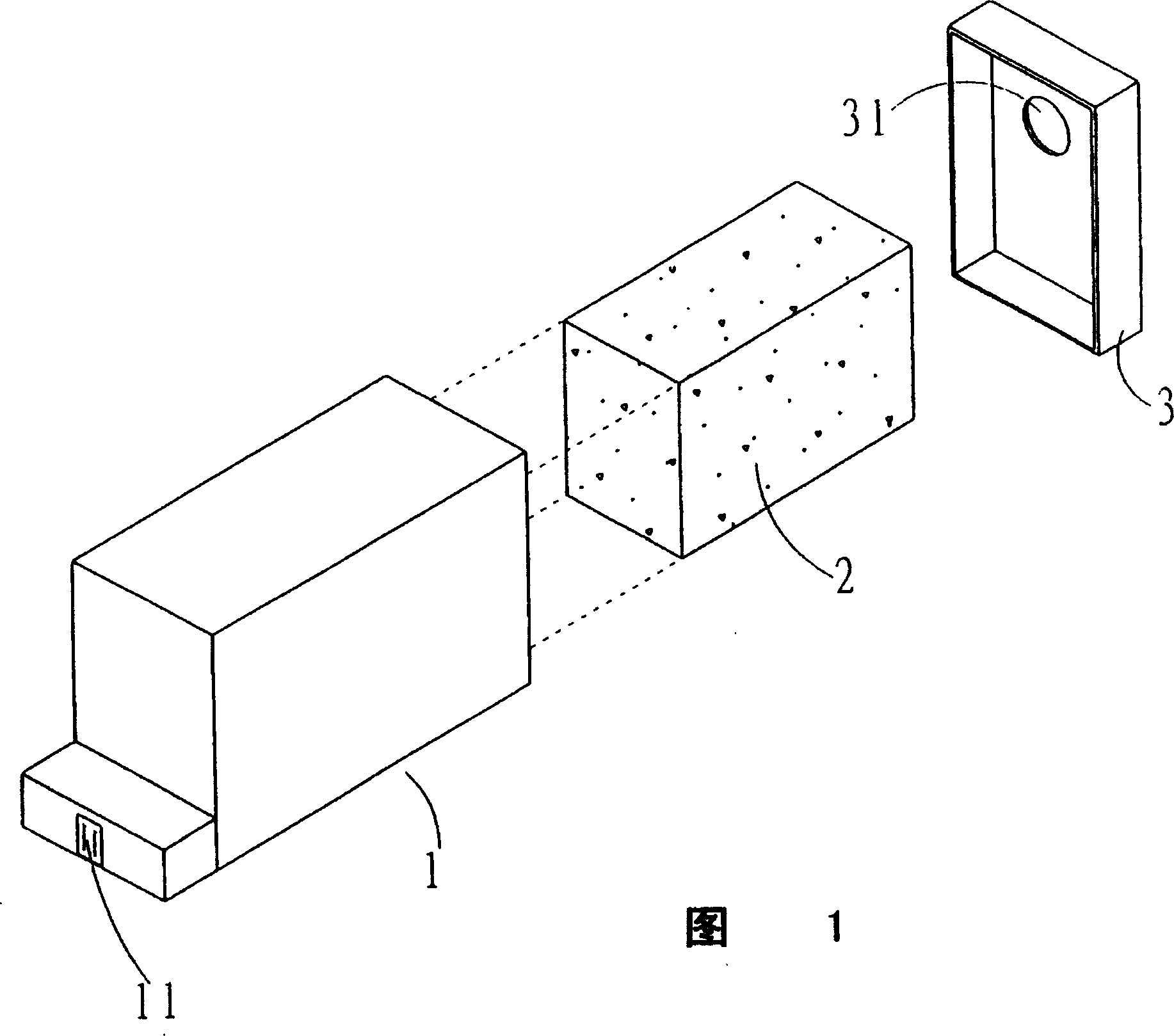

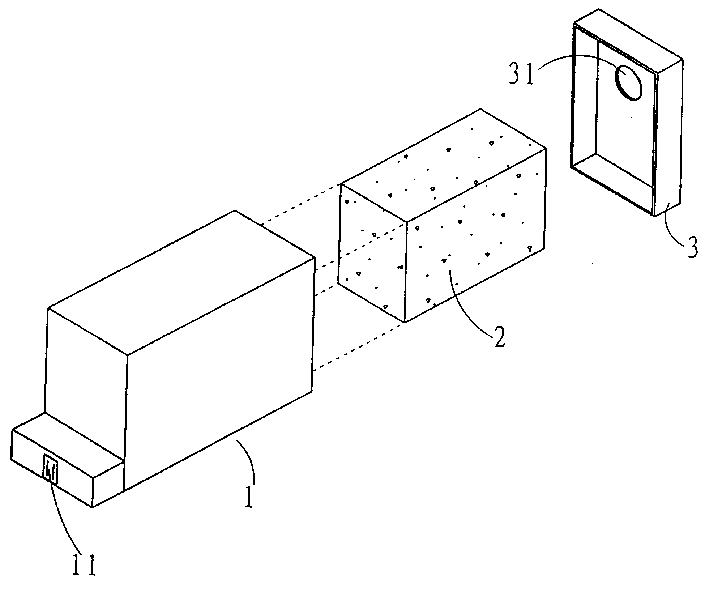

[0017] Figure 1 shows an exploded view of the ink supply cartridge, where the ink supply cartridge is installed in the inkjet printer to provide ink required for printing. As shown in the figure, the ink supply cartridge includes: a casing 1 , a fibrous ink storage material 2 and an upper cover 3 . The casing 1 is a hollow cassette for containing ink and ink storage material 2 . A inkjet head (printhead) 11 is formed on one side of the housing 1, and the inkjet head 11 has a plurality of openings (not shown), and the ink can be ejected automatically by the signal of the inkjet printer and adhered to it. Printing media (such as: paper), so as to complete the printing work.

[0018] After the fibrous ink storage material 2 is put into the casing 1, the ink supply cartridge is sealed with the upper cover 3, and then the ink is injected through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com