A secondary dedusting device for vertical corn processing

A corn processing and secondary dust removal technology, which is applied to the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems of large area, single dust removal structure, incomplete dust removal, etc. To achieve the effect of improving the processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

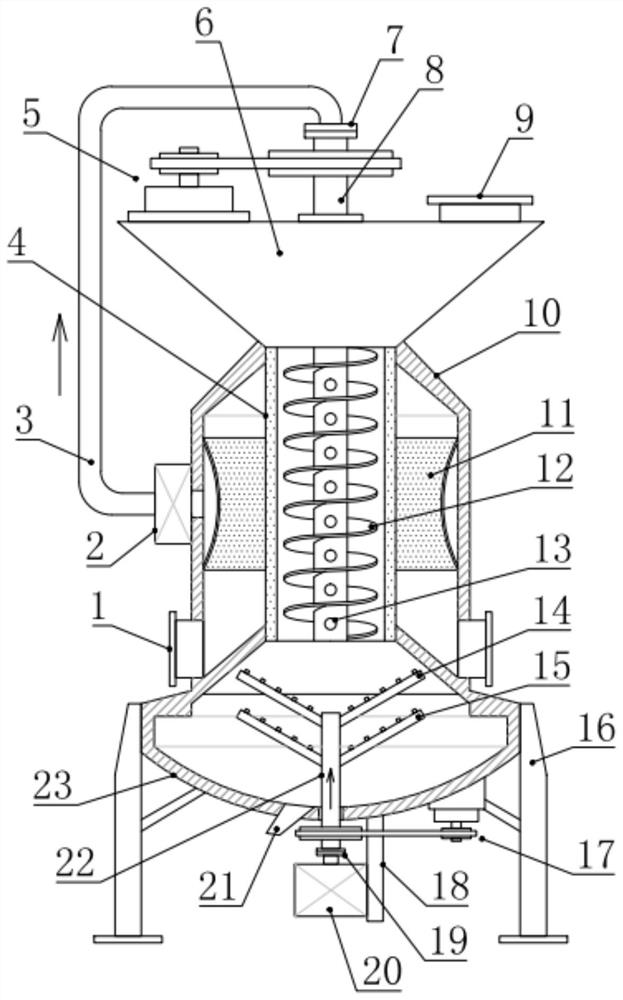

[0018] see Figure 1-4 , in an embodiment of the present invention, a vertical corn processing secondary dedusting device comprises a storage box 6, an upper body 10 and a lower body 23, the upper end of the upper body 10 is equipped with a storage box 6, and the upper body 10 The lower end of the lower body 23 is installed, and the outer side of the lower body 23 is also provided with a plurality of support legs 16 in a circumferential distribution, and the device can be stably supported by the support legs 16; the top of the storage box 6 is provided with a feed port 9, The bottom of the lower body 23 is provided with a discharge port 21 , and the side bottom of the upper body 10 is provided with a plurality of dust outlets 1 circumferentially.

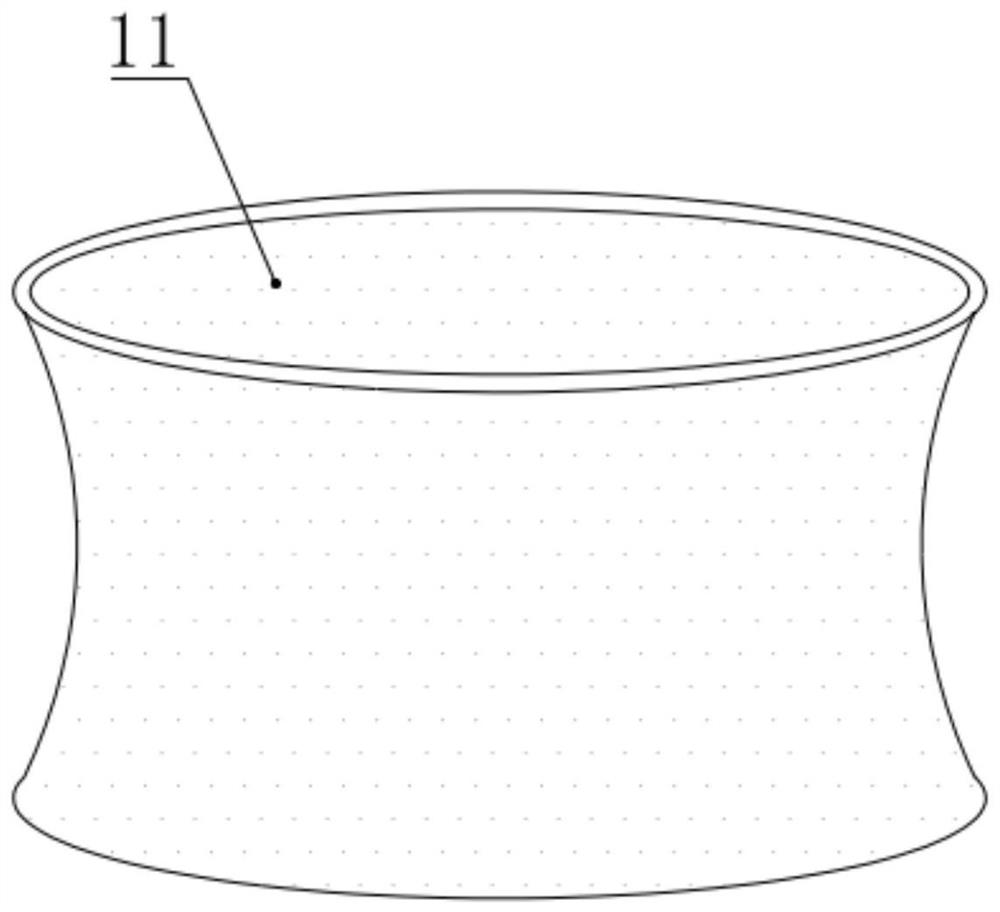

[0019] The inner side of the upper body 10 is installed and fixed with a dust removal net cylinder 4, and the dust removal net cylinder 4 is a cylindrical cylinder structure arranged vertically. Fixedly connected, and the dedusting...

Embodiment 2

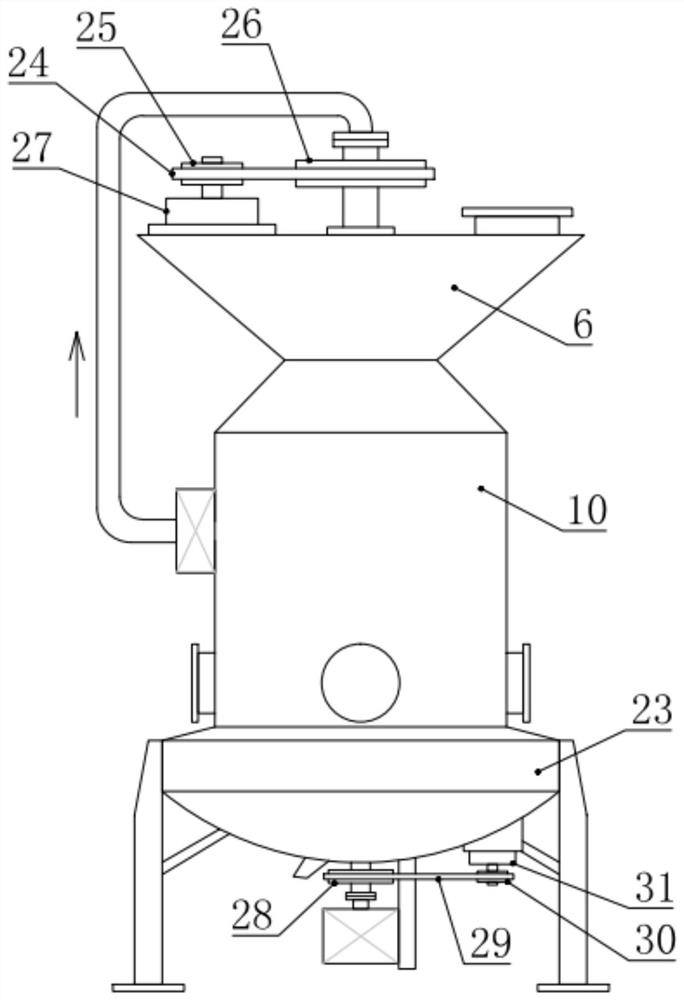

[0023] see figure 2 , the difference between this embodiment and embodiment 1 is:

[0024] In this embodiment, the first driving mechanism 5 includes a first transmission belt 24, a first driving pulley 25, a first driven pulley 26 and a first motor 27, and the first motor 27 is installed and fixed on the storage box 6, the first driving pulley 25 is installed and fixed on the output shaft of the first motor 27, and the first driving pulley 25 is connected with the first driven pulley 26 through the first transmission belt 24, and the first driven belt Wheel 26 is installed and fixed on the upper center pipe 8 at the top of the material storage box 6 .

[0025] In this embodiment, the second driving mechanism 17 includes a second driven pulley 28, a second transmission belt 29, a second driving pulley 30, and a second motor 31, and the second motor 31 is fixed on the bottom of the lower body 23. At the bottom, a second driving pulley 30 is installed and fixed on the output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com