Inner rotor for drum-type permanent magnet speed regulator and drum-type permanent magnet speed regulator

A technology of permanent magnet governor and inner rotor, applied in permanent magnet clutches/brakes, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as insufficient heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

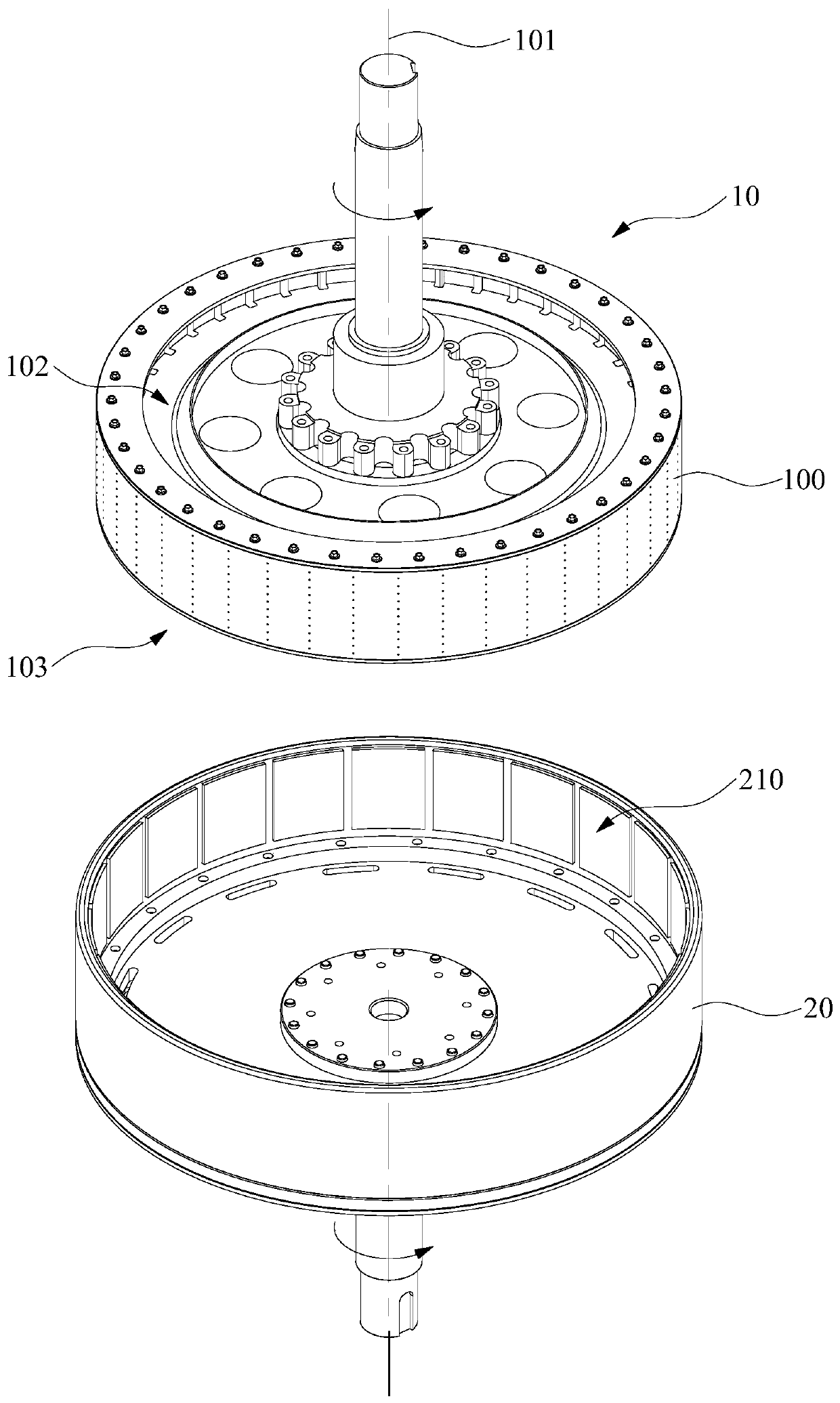

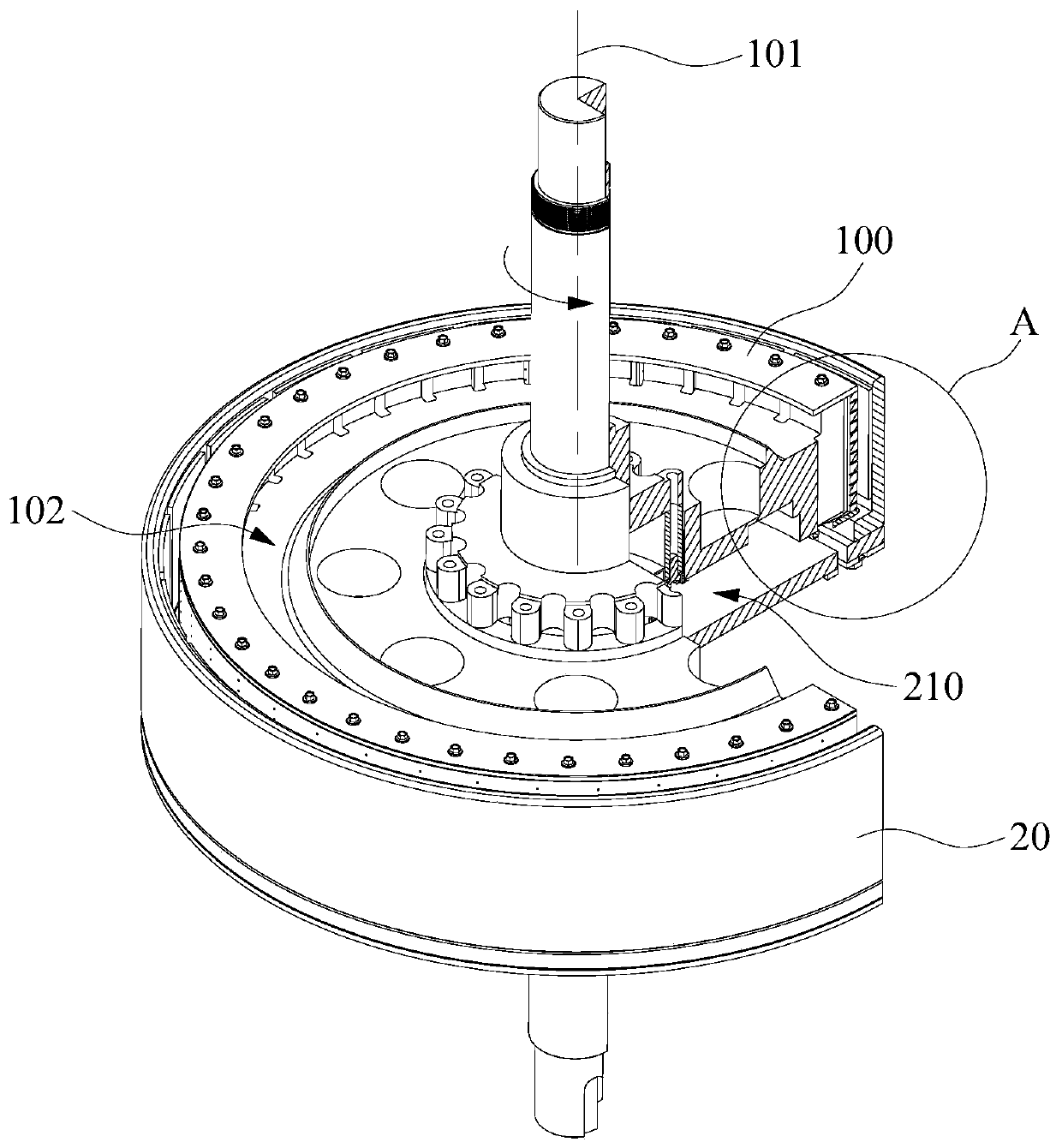

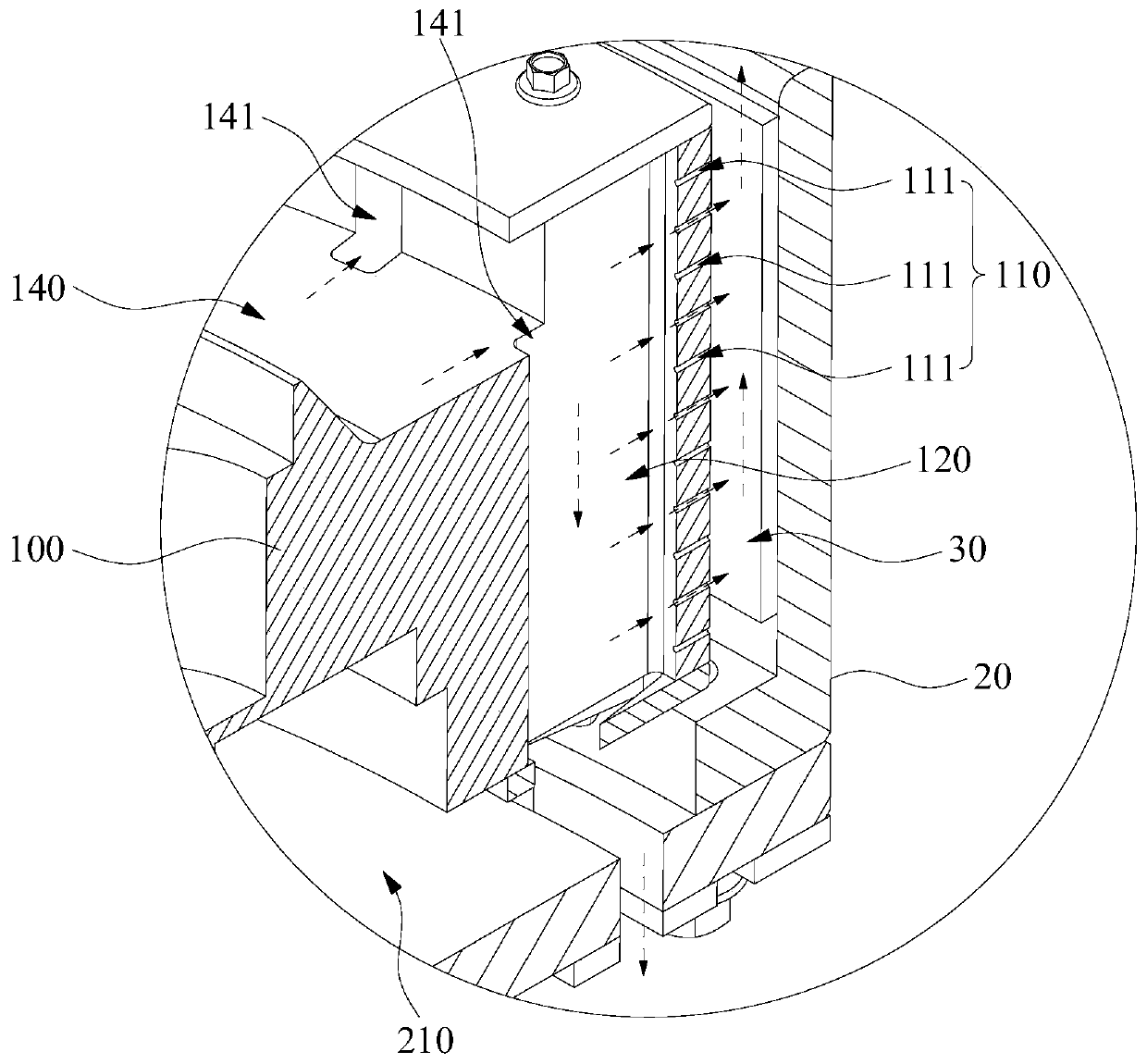

[0031] to combine image 3 , Figure 4 As shown, in one embodiment, an inner rotor 10 for a cylindrical permanent magnet governor includes an inner rotor body 100, and a centrifugal flow channel 110 is arranged inside the inner rotor body 100, and the outlet of the centrifugal flow channel 110 is located at on the radially outer peripheral surface of the inner rotor body 100 .

[0032] The inner rotor 10 for the above-mentioned cylindrical permanent magnet governor, combined with figure 1 , figure 2 and image 3As shown, when in use, the outer rotor 20 is used in conjunction with the inner rotor 10 for the cylindrical permanent magnet governor. The outer rotor 20 is provided with an accommodating cavity 210 , the inner rotor 10 is installed in the accommodating cavity 210 , and the radially outer peripheral surface of the inner rotor body 100 cooperates with the inner wall of the accommodating cavity 210 to form an air gap 30 . Since the outlet of the centrifugal channel...

Embodiment approach 2

[0052] to combine figure 1 , figure 2 and image 3 As shown, a cylindrical permanent magnet speed governor includes an outer rotor 20 and an inner rotor 10 for the cylindrical permanent magnet speed governor in any of the above-mentioned embodiments; the outer rotor 20 is provided with an accommodation cavity 210; the The inner rotor 10 is installed in the accommodating cavity 210 , and the radially outer peripheral surface of the inner rotor body 100 cooperates with the inner wall of the accommodating cavity 210 to form an air gap 30 .

[0053] The drum type permanent magnet governor includes an inner rotor 10 and an outer rotor 20 . The outer rotor 20 is provided with an accommodating cavity 210 , the inner rotor 10 is installed in the accommodating cavity 210 , and the radially outer peripheral surface of the inner rotor body 100 cooperates with the inner wall of the accommodating cavity 210 to form an air gap 30 . Since the outlet of the centrifugal channel 110 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com