An anti-vehicle retrograde device with self-cleaning function

A self-cleaning, functional technology, applied in the field of traffic safety, can solve problems such as large safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

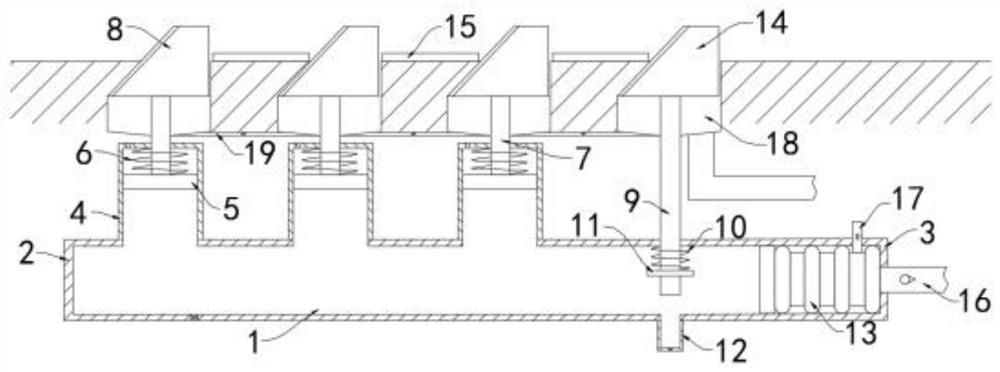

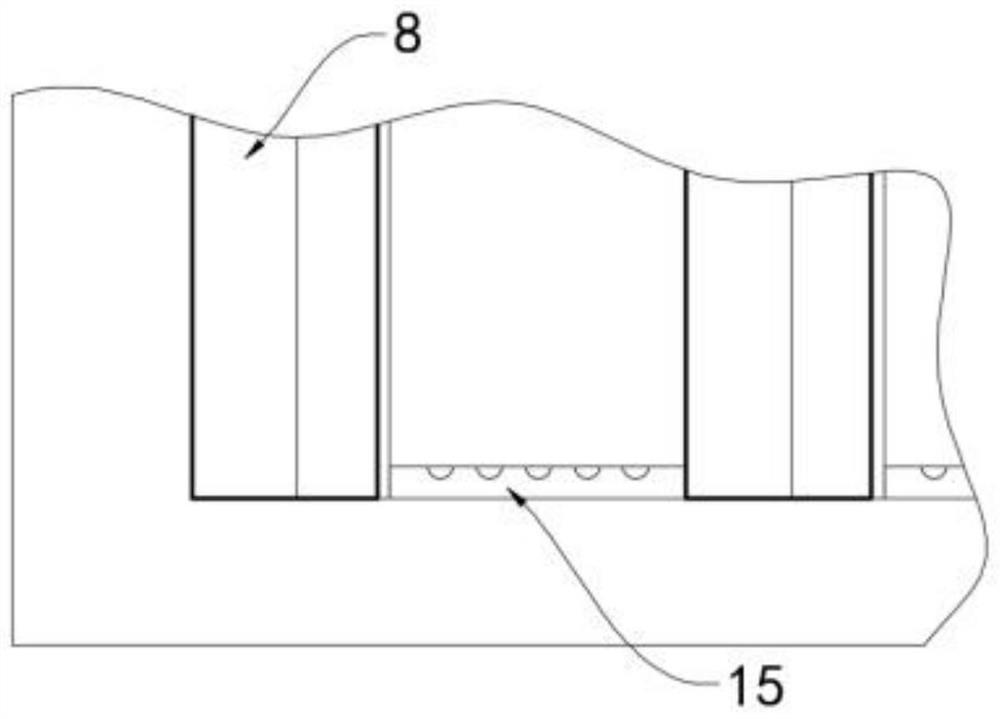

[0023] Such as Figure 1-2 As shown, a self-cleaning anti-vehicle retrograde device includes a main pipe 1 arranged below the ground and arranged horizontally. The side wall of the main pipe 1 is provided with a single row of air intake holes. The main pipe 1 has good wear resistance and sealing It can be an ordinary plastic pipe. The main pipe 1 includes a forward end 2 and a reverse end 3 with both ends sealed. The car travels from the forward end 2 to the reverse end 3. The end 2 runs in the reverse direction, and the upper side wall of the main pipe 1 is fixedly connected with a plurality of sub-pipes 4 that are all vertically arranged, and the upper ends of the plurality of sub-pipes 4 are all sealed.

[0024] Each branch pipe 4 is sealed and slidably connected with a horizontally arranged sliding plate 5, and a back-moving spring 6 is fixedly connected between the sliding plate 5 and the inner top surface of the branch pipe 4. The back-moving spring 6 is in a contracted ...

Embodiment 2

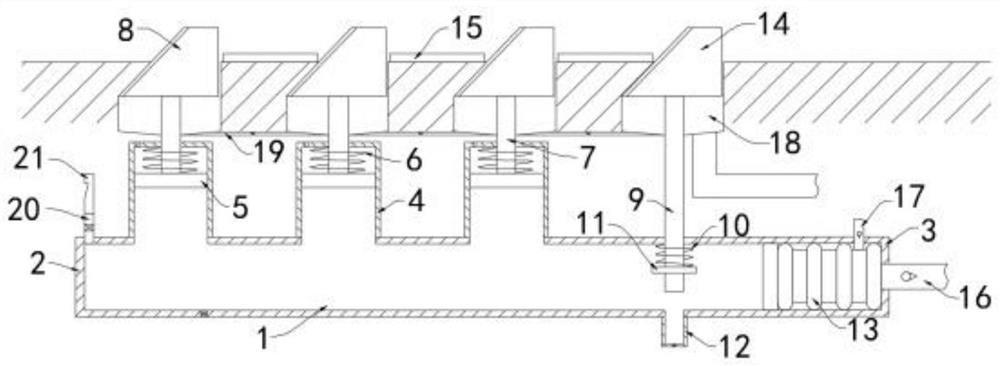

[0034] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that an air outlet pipe 20 is fixedly communicated with the side wall of the antegrade end 2 of the main pipe 1, and the other end of the air outlet pipe 20 is fixedly connected with a warning whistle 21, and the air outlet pipe 20 There is a flow-limiting one-way valve inside, and when the air pressure in the main pipe 1 reaches the limit value of the flow-limiting one-way valve, the gas in the pipe will be discharged through the outlet pipe 20 .

[0035] In this embodiment, when the car is running in the reverse direction, the anti-reverse main belt 14 will be pressed into the sealed tube 12 first, and when the wheel is pressed against the anti-reverse belt 8, not only will it cause a bumpy feeling, but the increased pressure in the main pipe 1 will Also can blow warning whistle 21 by air outlet pipe 20, carry out effective warning to driver.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com