Splicing type ultra-thin tire puncturing device

A tire breaker and splicing technology, applied in the field of security equipment, can solve the problems of inability to respond quickly, increase maintenance costs, and long opening time, and achieve the effects of simple structure, short response time, and fast response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

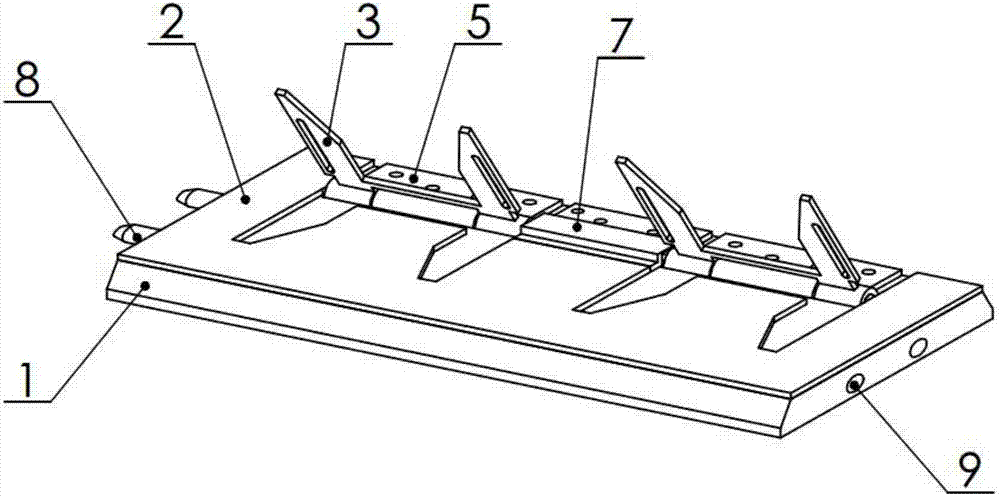

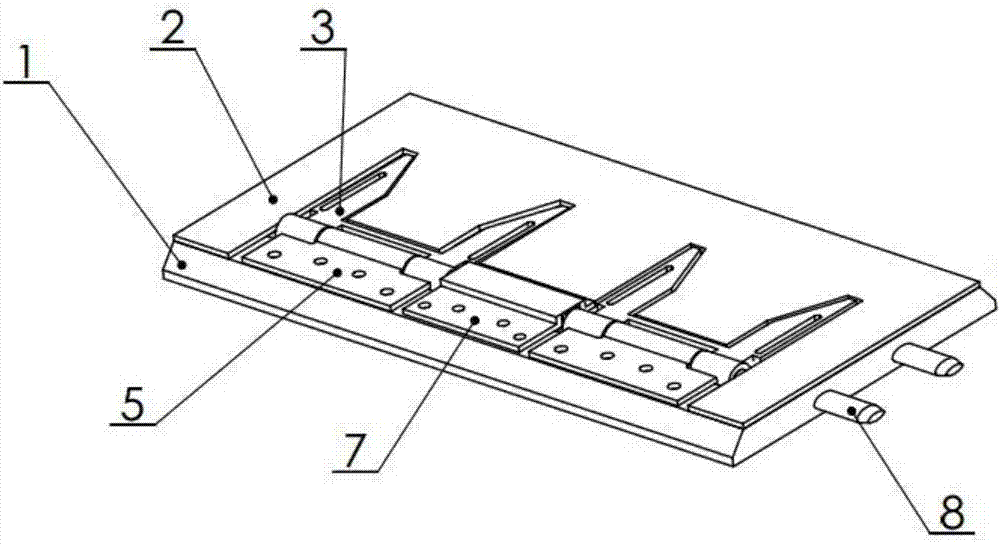

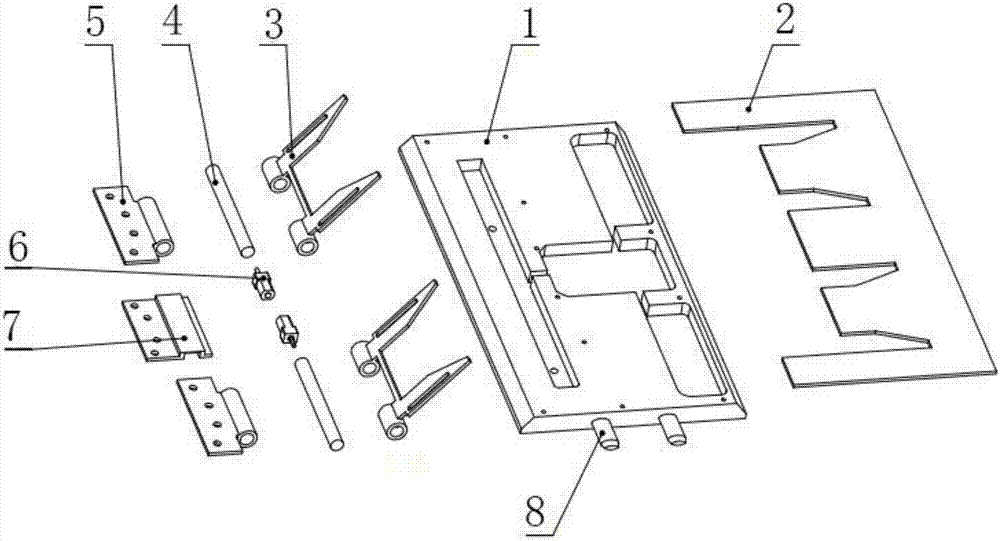

[0019] The invention provides a splicable ultra-thin tire breaker (see Figure 1-5 , referred to as tire breaker), is characterized in that the tire breaker includes a bottom plate 1, a cover plate 2, a tire breaking structure 3, a shaft 4, a hinge structure 5, a motor 6, a protective cover 7, a splicing head 8 and a splicing hole 9; The head end of the punctured tire structure 3 is a knife stab 31 with a flat structure shaped like a dagger, and the knife stab 31 has an elongated through hole. out of the tire, it will not be taken up by the tire due to the pressure difference; the tail end of the broken tire structure 3 is a shaft hole structure 32, and an axial through hole is opened in the inner axial direction; the end of the knife stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com