Damping motor convenient to move

A technology of shock-absorbing springs and movable rods, applied in electrical components, electromechanical devices, electric components, etc., can solve the problems of inconvenient movement and large motor vibration, and achieve the effect of solving large vibration, reducing vibration and protecting the motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020] Example 1

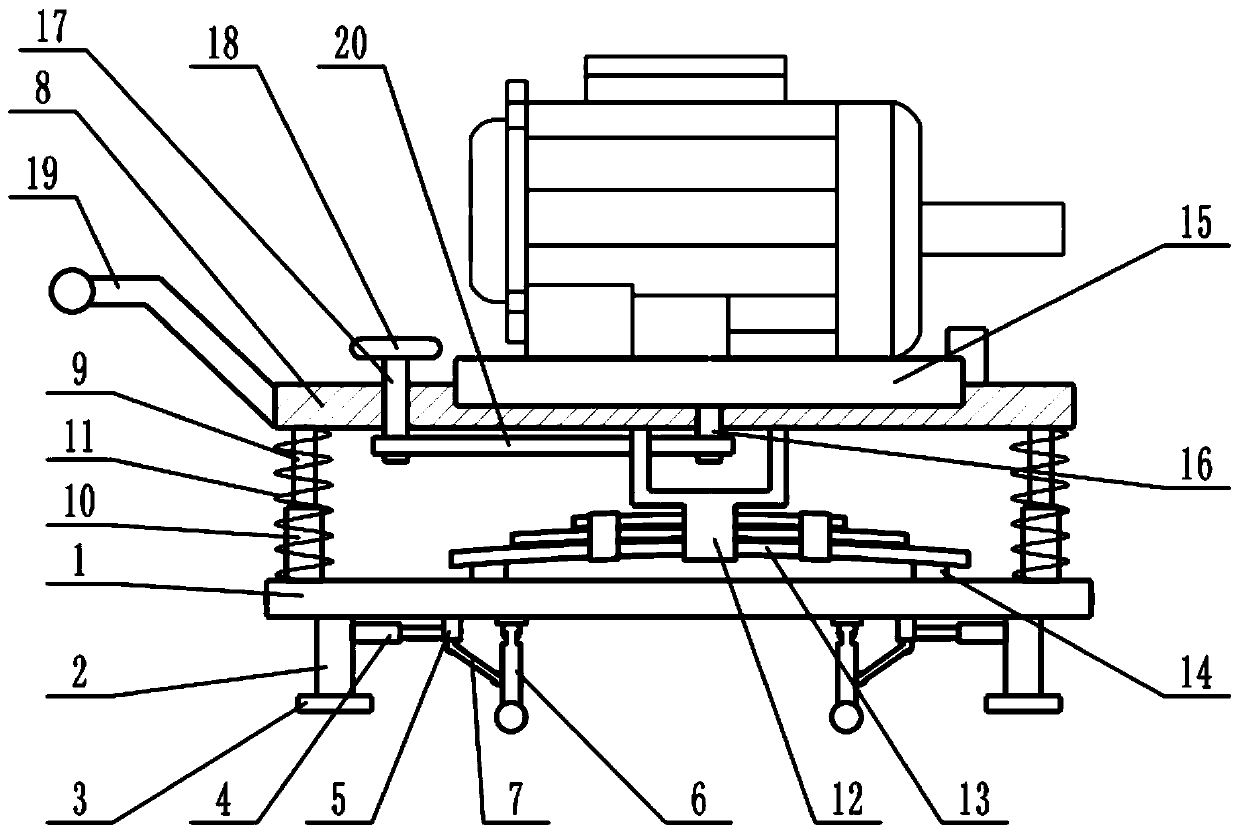

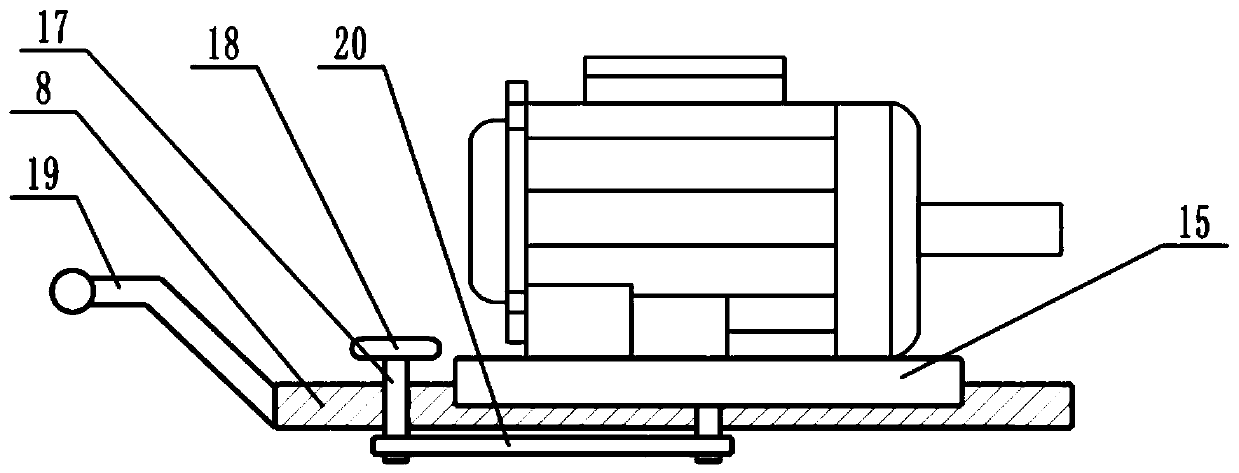

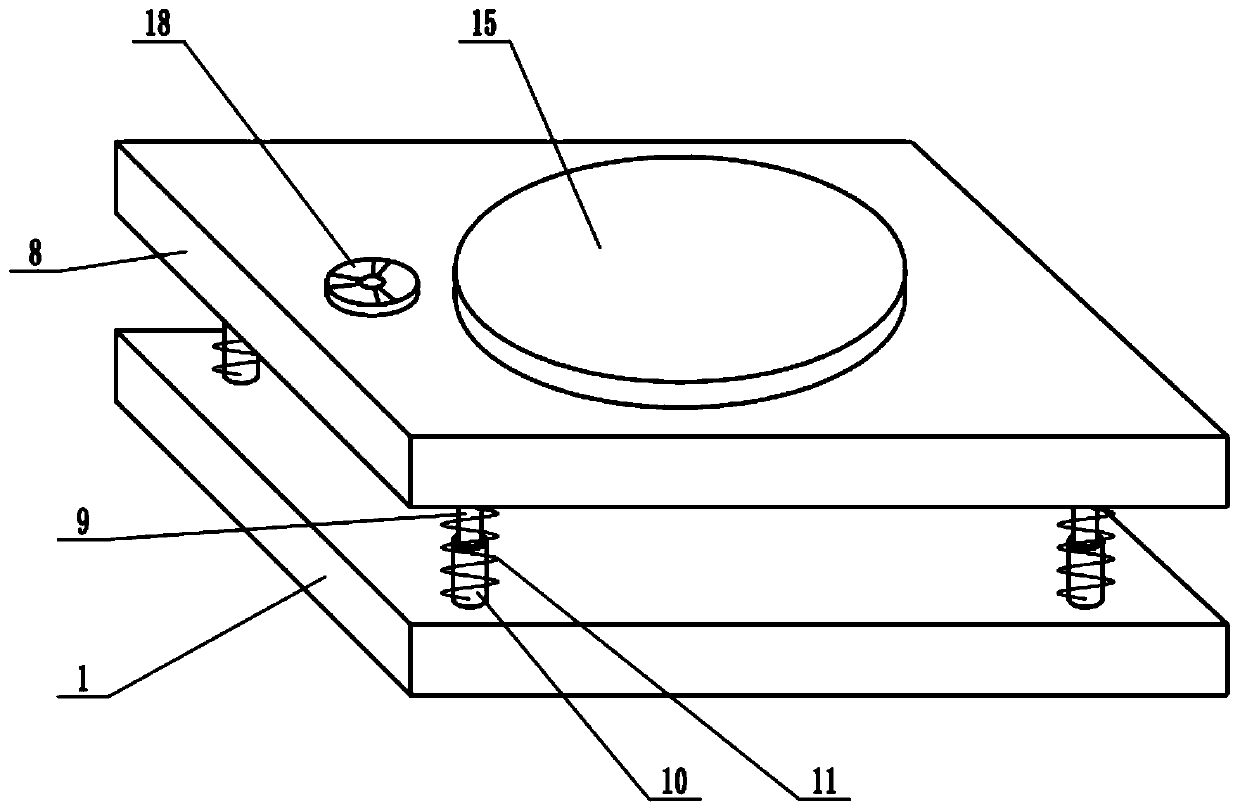

[0021] See Figure 1-3 In the embodiment of the present invention, a shock-absorbing motor that is easy to move includes a base 1, a fixing plate 2, a mounting plate 8 and a mounting frame 12. The lower surface of the base 1 is fixedly connected with a fixing plate 2, and the fixing plates 2 share Two are arranged symmetrically. A support plate 3 is installed at the bottom of the fixed plate 2. The support plate 3 is used to increase the contact area between the device and the ground, thereby improving the stability of the device. A mounting plate 8 is provided above the base 1 , The lower surface of the mounting plate 8 is fixedly connected with a guide rod 9, a sleeve 10 is sleeved under the guide rod 9, and the sleeve 10 is slidably connected to the guide rod 9, and the guide rod 9 can slide up and down in the sleeve 10. The lower end of 10 is fixedly connected with the upper surface of the base 1, a shock-absorbing spring 11 is sleeved on the sleeve 10, th...

Example Embodiment

[0022] Example 2

[0023] On the basis of embodiment 1, a moving mechanism is installed under the base 1. The moving mechanism includes a telescopic mechanism 4, a slider 5, a movable rod 6 and a connecting rod 7, and the side wall of the fixed plate 2 is fixedly connected with the telescopic mechanism 4. The telescopic mechanism 4 is an electro-hydraulic telescopic cylinder. The extension end of the telescopic mechanism 4 is fixedly connected with a slider 5, and the slider 5 is slidably connected to the lower surface of the base 1. The telescopic mechanism 4 is controlled to expand and contract, and the slider 5 can be driven along the base. The lower surface of the base 1 slides left and right, the lower surface of the base 1 is hinged with a movable rod 6, the lower end of the movable rod 6 is equipped with a roller, the lower surface of the slider 5 is hinged with a connecting rod 7, and the lower end of the connecting rod 7 is connected with the movable rod 6. The middle pa...

Example

[0024] Combining Embodiment 1 and Embodiment 2, the working principle of the present invention is: install the motor on the turntable 15 and rotate the turntable 18, and the rotating shaft 16 can be driven by the transmission belt 20 to rotate, thereby driving the turntable 15 to rotate. Adjust the motor according to actual installation requirements. The orientation is very convenient. When it is rotated to a proper position, the turntable 15 is locked by the positioning buckle to keep the turntable 15 and the mounting plate 8 relatively fixed. During the operation of the motor, the shock-absorbing spring 11 and the plate spring 13 can be used In order to reduce the vibration of the device during operation, the effect of reducing noise and protecting the motor is achieved. When the device needs to be moved, the telescopic mechanism 4 is controlled to extend, and the movable rod 6 is driven to rotate in the vertical direction. The roller moves down to make the roller meet the gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com