Hanger for bent tube zinc plating

A technology of elbow and hanger, which is applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of unstable fixing of elbows, and achieve the effect of improving stability and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

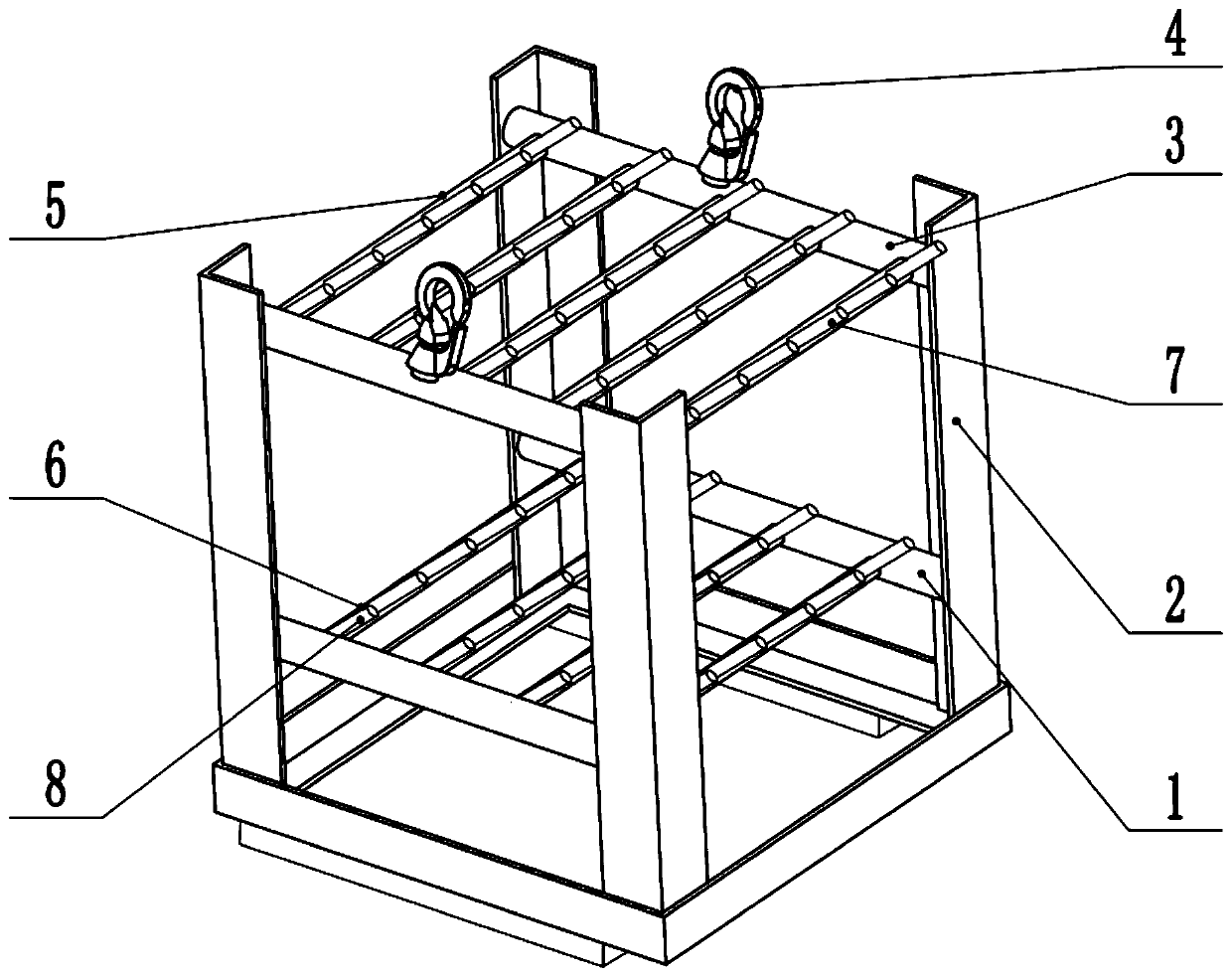

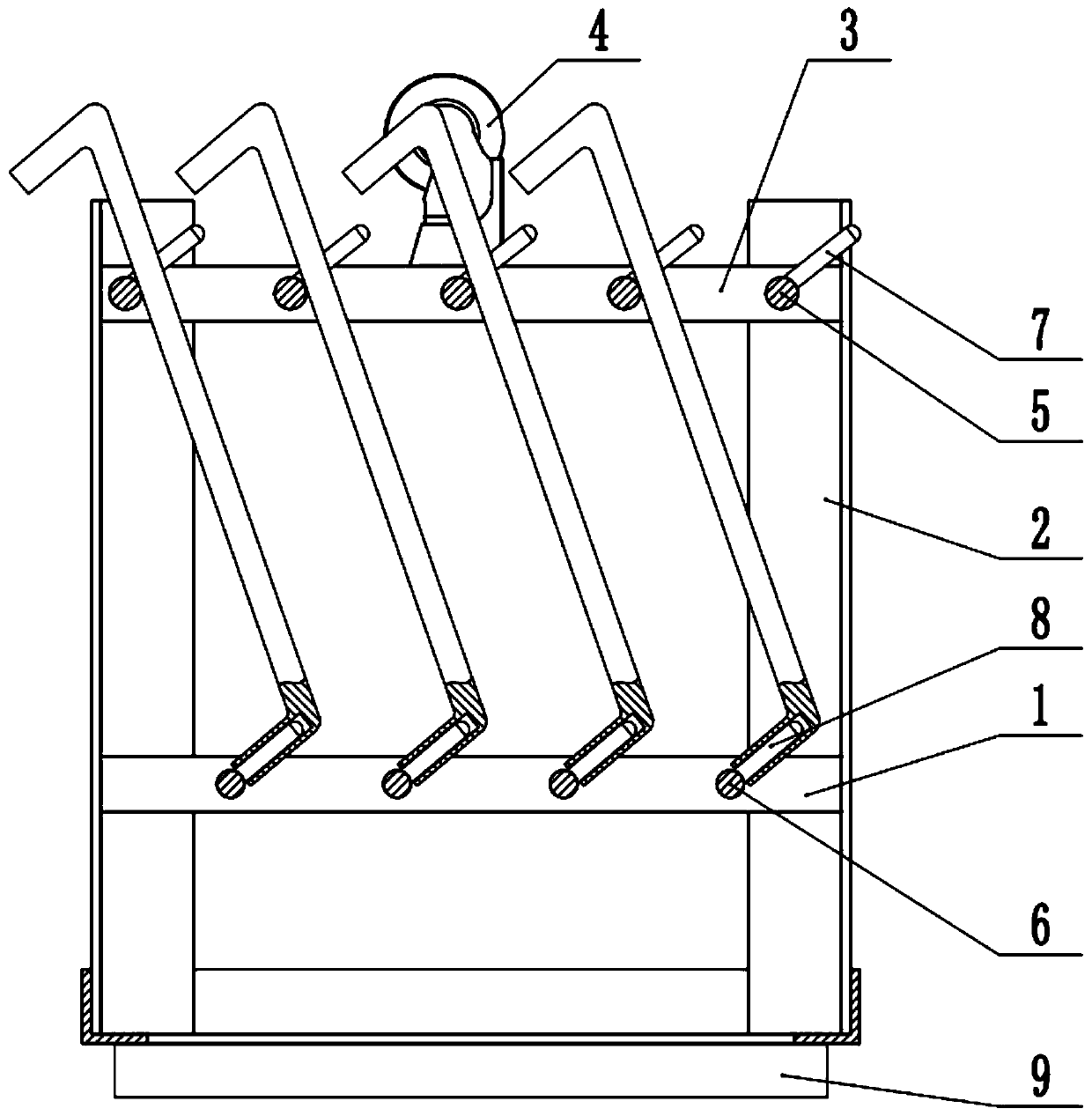

[0035] Basic as attached figure 1 with attached figure 2 Shown: a hanger for galvanizing bent pipes, including a bracket, and the bracket includes an upper support frame 3 and a lower support frame 1. The lower support frame 1 has a rectangular frame structure, and the top walls of the four corners of the lower support frame 1 are respectively vertically welded and fixed with a support column 2, and the four support columns 2 have the same shape, size and structure. The top of the support column 2 is fixed with an upper support frame 3 by welding, the upper support frame 3 is a rectangular frame structure, and a hanging ear 4 is respectively welded and fixed on the top walls of the two opposite sides of the upper support frame 3, and the hanging ear 4 Vertically fixed on the top of the upper support frame 3. Five rows of parallel first support rods 5 are arranged in the rectangular frame enclosed by the upper support frame 3 , and the axial ends of the first support rods 5 ...

Embodiment 2

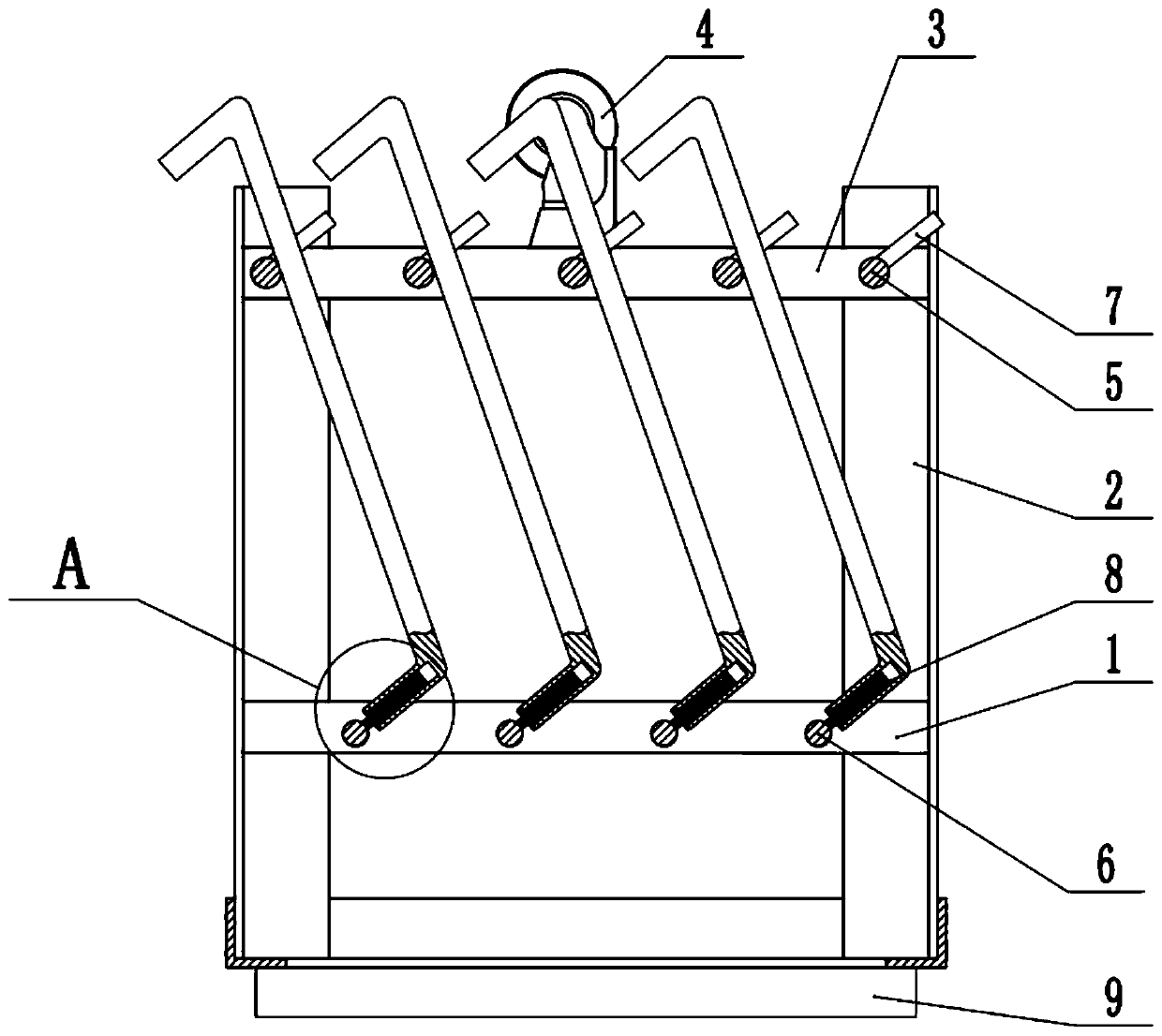

[0039] The difference between this embodiment and Embodiment 1 is that, as attached image 3 with attached Figure 4 As shown, the second column 8 includes a fixed rod 10 and a sleeve 11 , and the sleeve 11 is slidably connected to the fixed rod 10 in the axial direction. Wherein the fixed rod 10 is welded and fixed on the outer wall of the first support rod 5, and the angle between the fixed rod 10 and the horizontal plane is 15°. An annular baffle 12 is welded and fixed on the outer wall of the sleeve 11 close to the second support rod 6 along the circumferential direction, and the outer diameter of the annular baffle 12 is 8 mm larger than the outer diameter of the end of the elbow. A compression spring 13 is plugged and fixed between the inner wall of the sleeve 11 and the free end of the fixed rod 10 , and the sleeve 11 abuts against the outer wall of the second support rod 6 when the compression spring 13 is compressed to the extreme.

[0040]The specific implementatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com