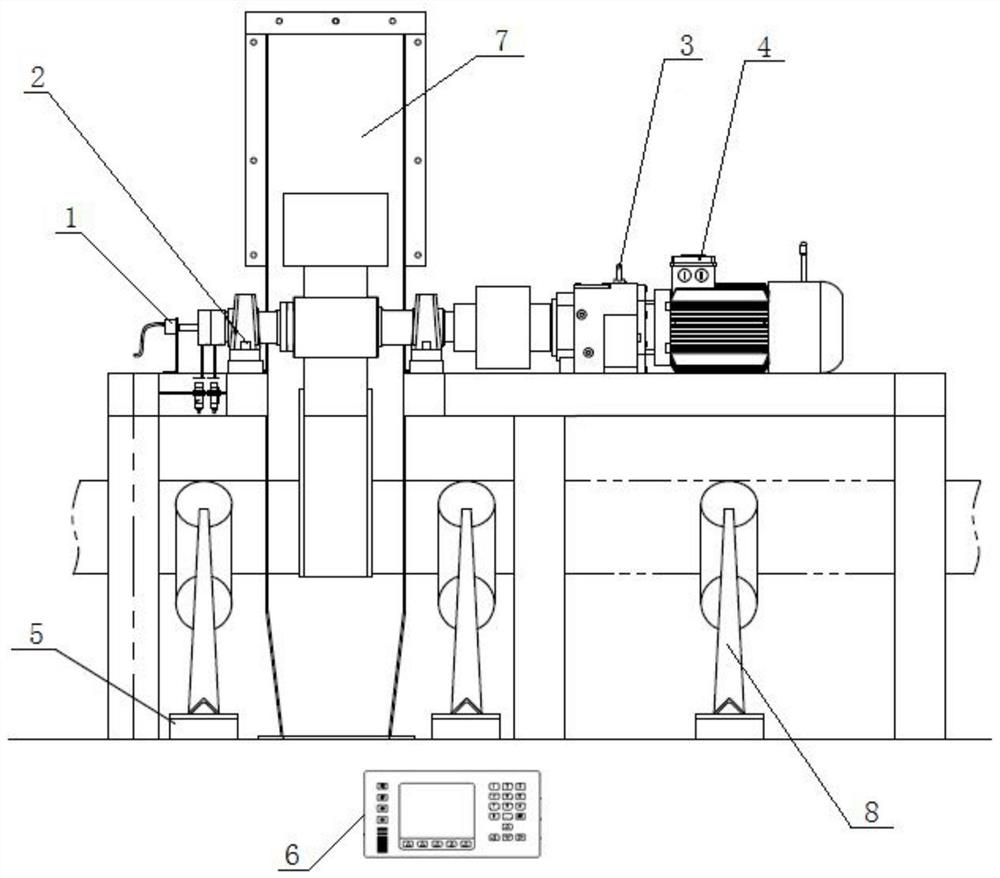

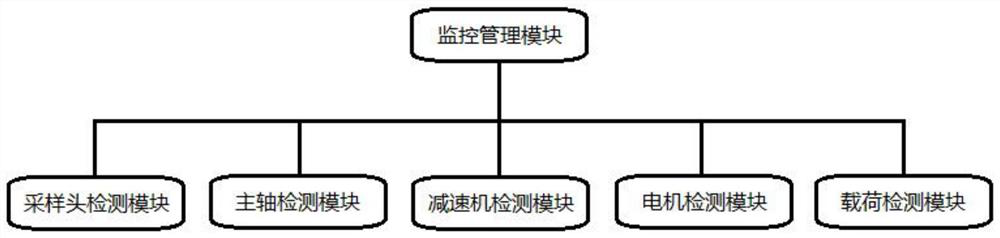

Fault monitoring device for belt sampling head and diagnostic method for fault early warning

A technology of fault early warning and diagnostic methods, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., and can solve problems such as poor working environment, spindle fracture, production and safety impacts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] S1. According to the maximum load of 1000kg / m conveyed by the conveyor, the load interval is divided into 10 equal parts, that is, W 1 , W 2 …W 10 , where W 1 0~100kg / m, W 2 101~200kg / m, and so on, W 10 901~1000kg / m;

[0054] S2. After the belt sampling head device is installed and debugged, run for the first time, record the load weight on the conveyor at this time as 350kg / m, and record the first record W 4 (1) [Q 1 , F 1 , T 1 , I 1 ], the number of runs J 4 Increased by 1 from the initial value of 0, that is, J 4 is 1, where Q 1 is the position angle at the end of the first run of the sampling head, F 1 is the average vibration frequency of the spindle during the first run of the sampling head, T 1 is the average vibration frequency of the reducer during the first run of the sampling head, I 1 is the average current of the motor during the first run of the sampling head;

[0055] S3. When the belt sampling head runs for the second time, record the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com