Wire feeding device of wire cutting machine

A wire feeding device and wire cutting machine technology, applied in the directions of transportation and packaging, conveying filamentous materials, thin material handling, etc. The effect of stable cutting line length, guaranteeing service life and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

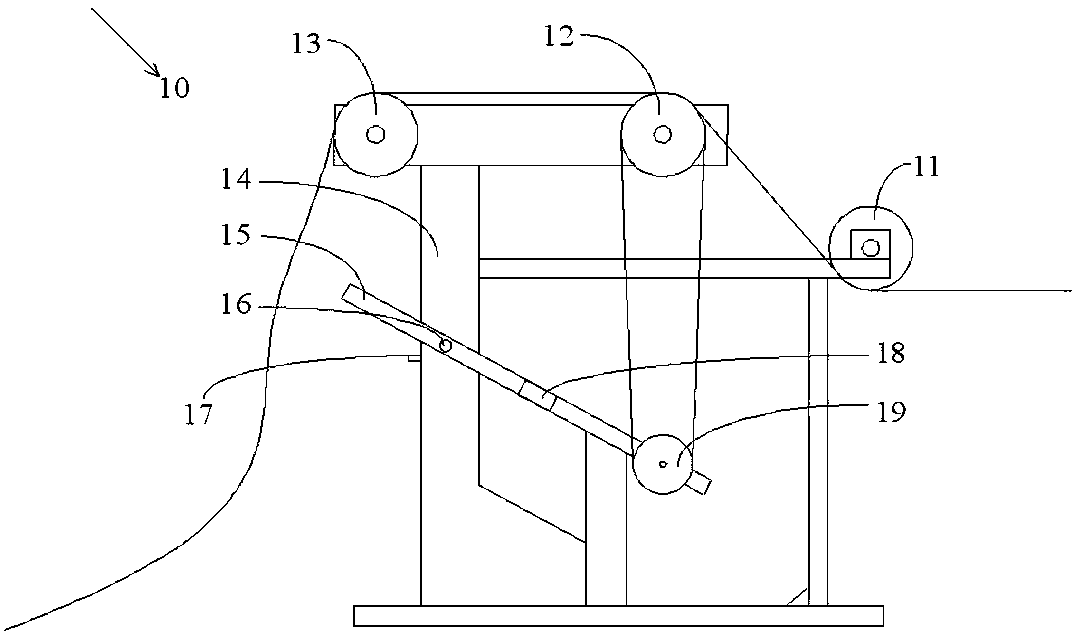

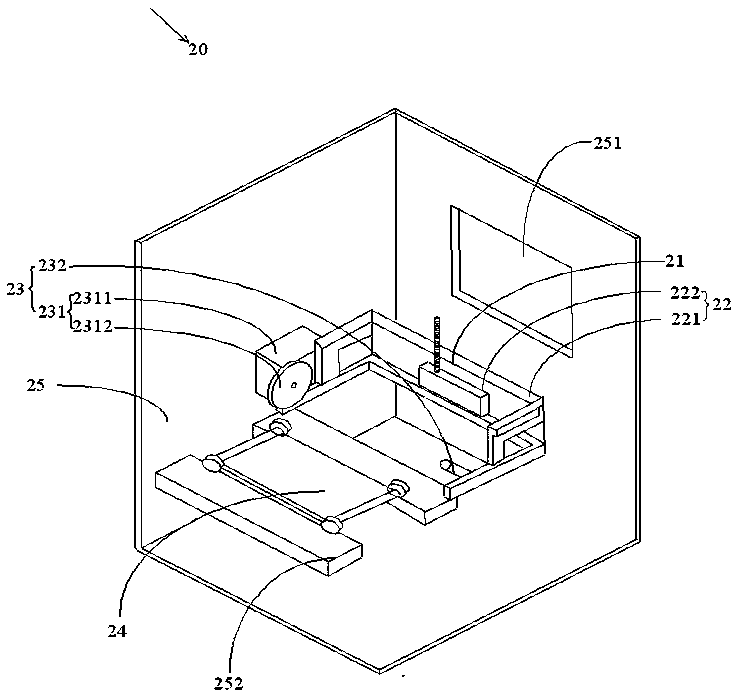

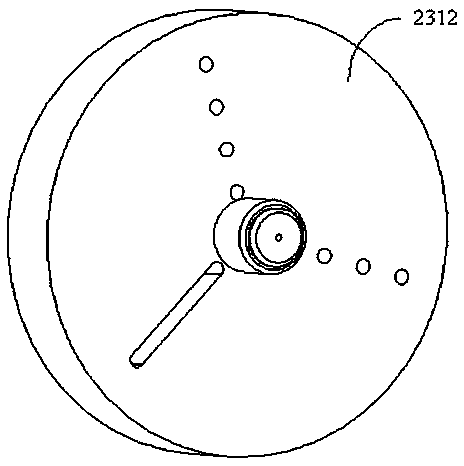

[0021] The present invention proposes a wire feeding device for a wire cutting machine, referring to Figure 1 to Figure 4 The wire feeding device of the wire cutting machine includes: an upper wire mechanism 20 and a winding wheel mechanism 10; the upper wire mechanism 20 includes: a mounting frame 21, a lifting assembly 22, a fastening assembly 23 and an upper wire assembly 24. In this embodiment, The mounting frame 21 is a groove-shaped setting with an opening on one side; supports are provided under both ends of the opening; the lifting assembly 22 is arranged below the mounting frame 21, and the lifting assembly is located The bottom of the opposite side of the opening is used to drive the rise and fall of the mounting frame 21; the fastening assembly 23 fastening assembly 23 includes a coaxial and opposite left fastening assembly 231 and a right fastening assembly 232, It is used for fixing and rotating the core of the spool 30; the upper wire component 24 is arranged un...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap