A wire feeding device for a wire cutting machine

A technology of wire feeding device and wire cutting machine, which is applied in the direction of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as overloading of wire cutting machine, affecting quality, equipment problems and product quality, etc., to achieve The length of the cutting line is stable, the service life is guaranteed, and the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

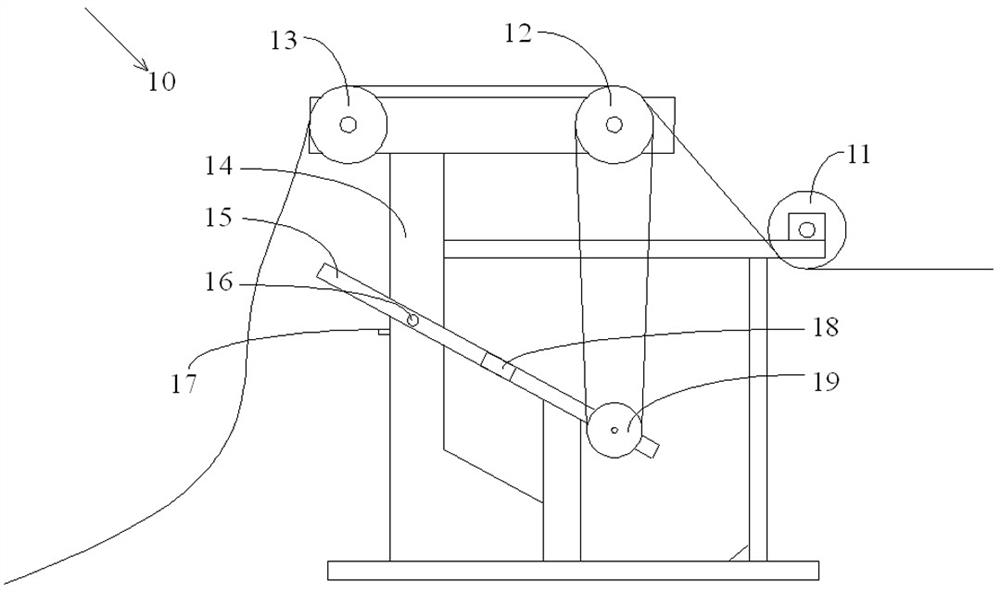

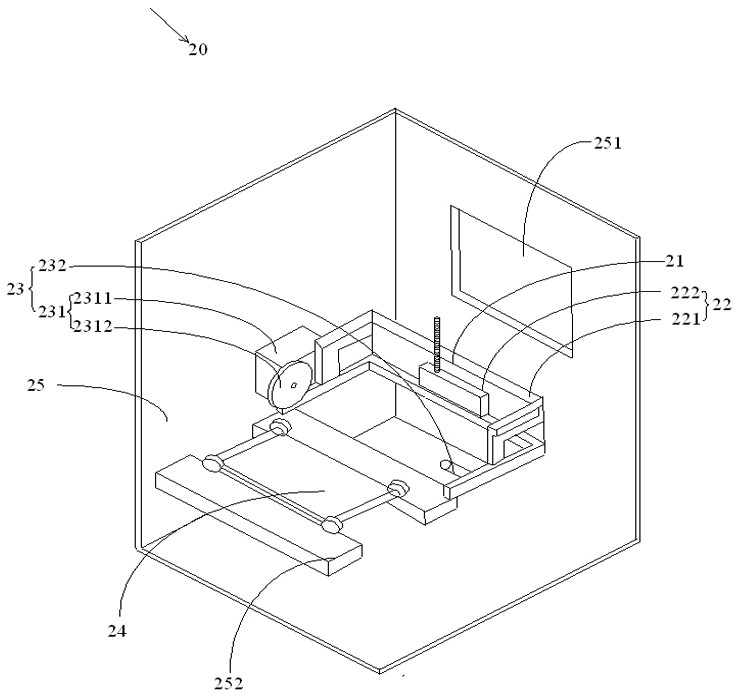

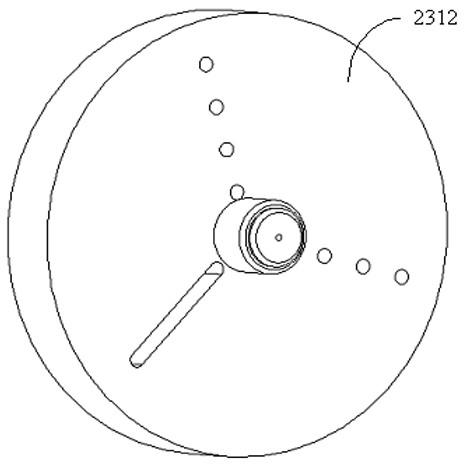

[0021] The present invention proposes a wire feeding device for a wire cutting machine, referring to Figure 1 to Figure 4 The wire feeding device of the wire cutting machine includes: an upper wire mechanism 20 and a winding wheel mechanism 10; the upper wire mechanism 20 includes: a mounting frame 21, a lifting assembly 22, a fastening assembly 23 and an upper wire assembly 24. In this embodiment, The mounting frame 21 is a groove-shaped setting with an opening on one side; supports are provided under both ends of the opening; the lifting assembly 22 is arranged below the mounting frame 21, and the lifting assembly is located The bottom of the opposite side of the opening is used to drive the rise and fall of the mounting frame 21; the fastening assembly 23 includes a coaxial and opposite left fastening assembly 231 and a right fastening assembly 232 for the bobbin 30 The fixing of the shaft core and the rotating wire feeding; the upper wire assembly 24 is arranged under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com