A variable-area foot plate

A foot plate and variable technology, applied in cranes and other directions, can solve the problems of inability to take into account the improvement of bearing capacity and limited space storage, and achieve the effects of convenient storage, convenient switching and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

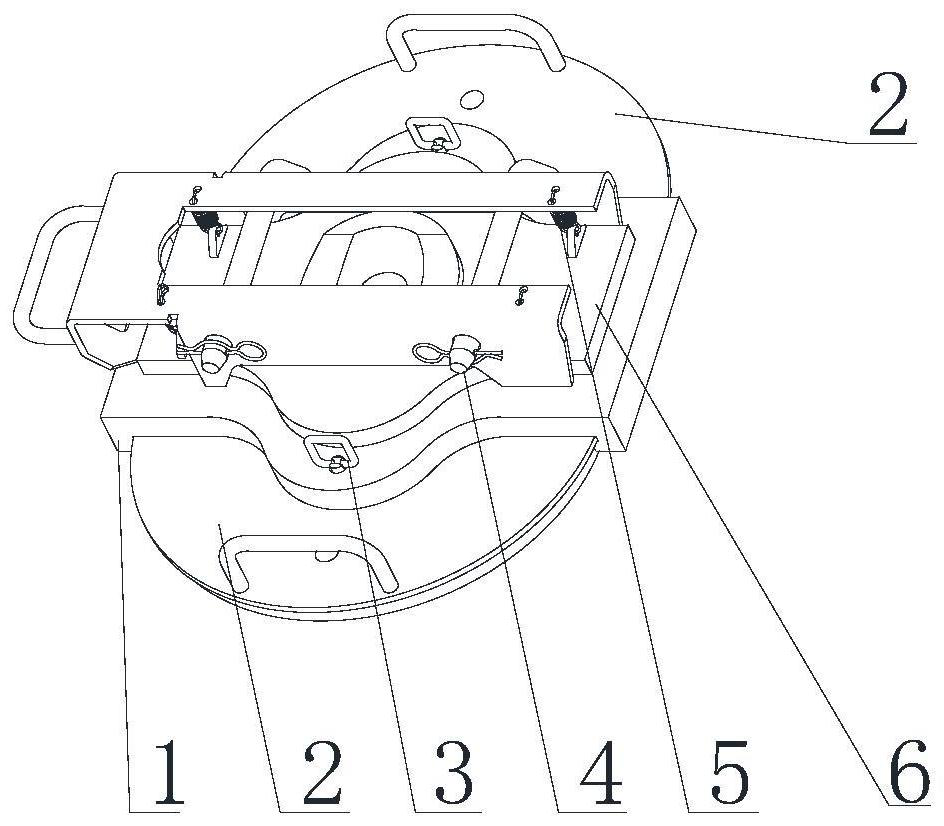

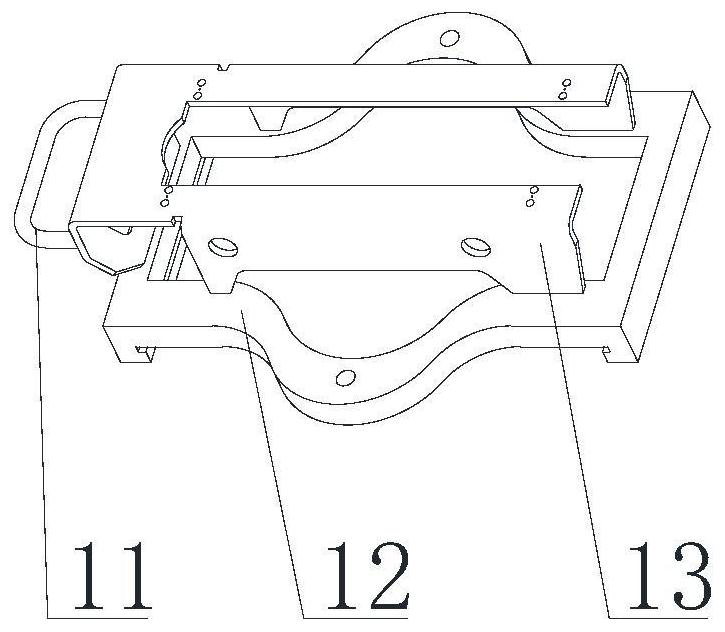

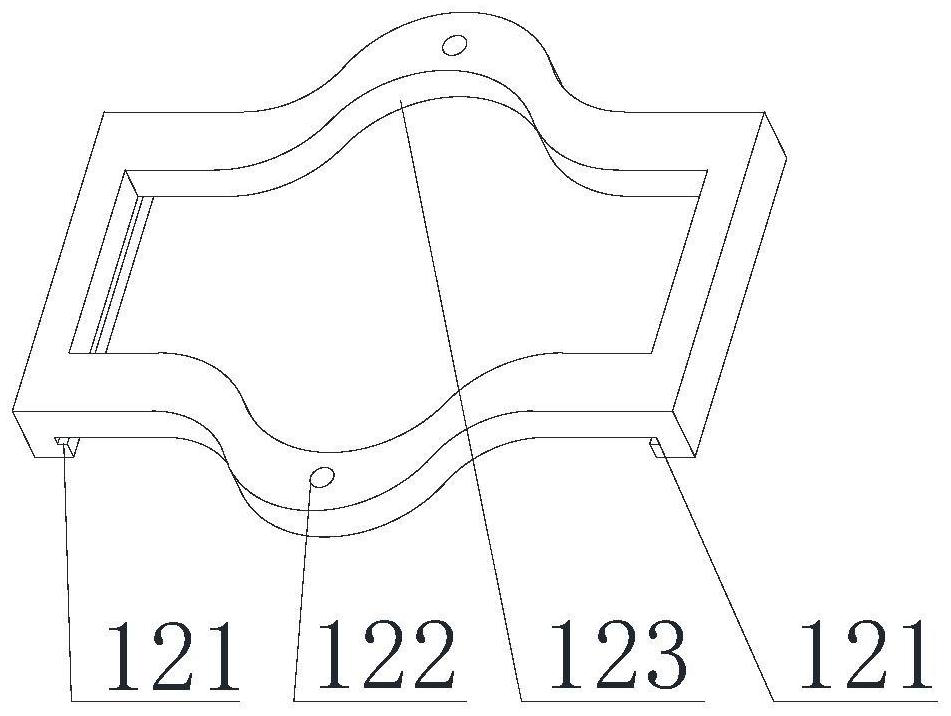

[0036] Such as Figure 1-9 As shown, the present invention provides a variable-area foot plate, including a support 1, a support plate 2, a support block 6, a first pin structure 3, a second pin structure 4 and a spring 5, the support 1 Including a support handle 11, a base 12 and a support base 13; the support handle 11 is arranged on one side of the support base 13 for storing the foot plate; the support base 13 is arranged on the base 12; the base 12 It includes an installation groove 121, a first support pin hole 122 and an accommodation cavity 123; the installation groove 121 is used to assemble the support plate 2, the first support pin hole 122 is used to assemble the first pin structure 3, and the accommodation cavity 123 is used for assembling support block 6. The support seat 13 includes a spring mounting hole 131, a second support pin hole 132 and a chute 133; the spring mounting hole 131 is used for assembling the spring 5, and the second support pin hole 132 is u...

Embodiment 2

[0043] Such as figure 1 As shown, the present invention provides an area-variable support plate, which includes a support 1, a support plate 2, a support block 6, a first pin structure 3, a second pin structure 4 and a spring 5, and the support 1 is a support leg The frame of the tray plays the role of storage operation of the foot tray and installation of other parts, such as Figure 2~4 shown. figure 2 It is the detailed structure of the support 1, and the support 1 includes a support handle 11, a base 12 and a support seat 13, and the support handle 11 is used to store the foot plate. base 12 as image 3 As shown, it includes a mounting groove 121, a first support pin hole 122 and an accommodating cavity 123. Wherein the mounting groove 121 is used for assembling the support plate 2, the first bearing pin hole 122 is used for assembling the first pin structure 3, and the accommodating cavity 123 is used for assembling the support block 6. Support seat 13 such as Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com