On-site air tightness test method for protective airtight door

A test method and technology of airtight doors, which are applied in the direction of liquid tightness measurement by using liquid/vacuum degree, and by measuring the rate of increase and deceleration of fluid, etc., can solve the problem that a single door cannot be tested for air tightness, consume manpower and material resources, and difficulties, etc. problem, to achieve the effect of improving reliability and measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

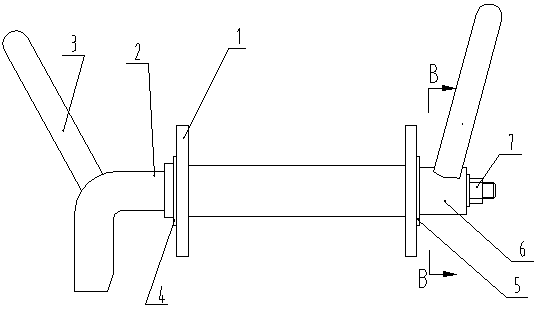

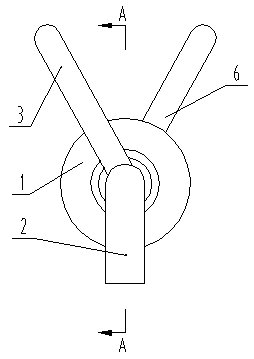

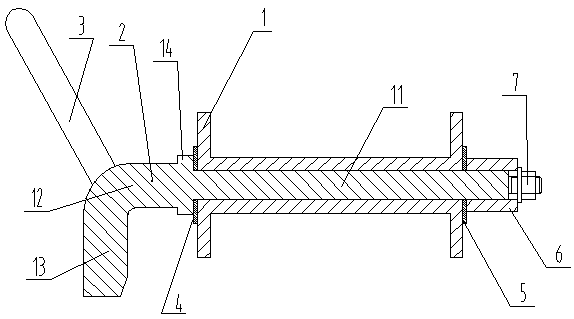

[0034] Now refer to Figure 6 to Figure 15 Describe the on-site airtightness test method embodiment of a kind of protective airtight door of the present invention, this test method is as follows:

[0035] S1. Preparation before the test:

[0036] S1.1. Remove the lock shafts of the upper lock 26 and the lower lock 21 of the protective airtight door 20, process two pieces of test lock shafts according to the shape of the lock shafts, and process the air hole 15 in the center of the test lock shafts. For the test lock shafts, see Figure 8 , the vent hole is used to protect the ventilation between the inside and the outside of the airtight door 20, and the orifice of the vent hole located on the outside is processed with a pipe thread, and the pipe thread is used to connect with the trachea joint of the sealing test equipment 24, and the test lock shaft After the processing is completed, two test lock shafts are respectively packed into the upper lock 26 and the lower lock 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com