A robot system maintenance method, device, robot and readable storage medium

A robot system and system maintenance technology, applied in the field of robots, can solve the problems of high robot system maintenance costs, robot system maintenance, etc., and achieve the effect of eliminating the inability to meet professional and debugging environment requirements, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

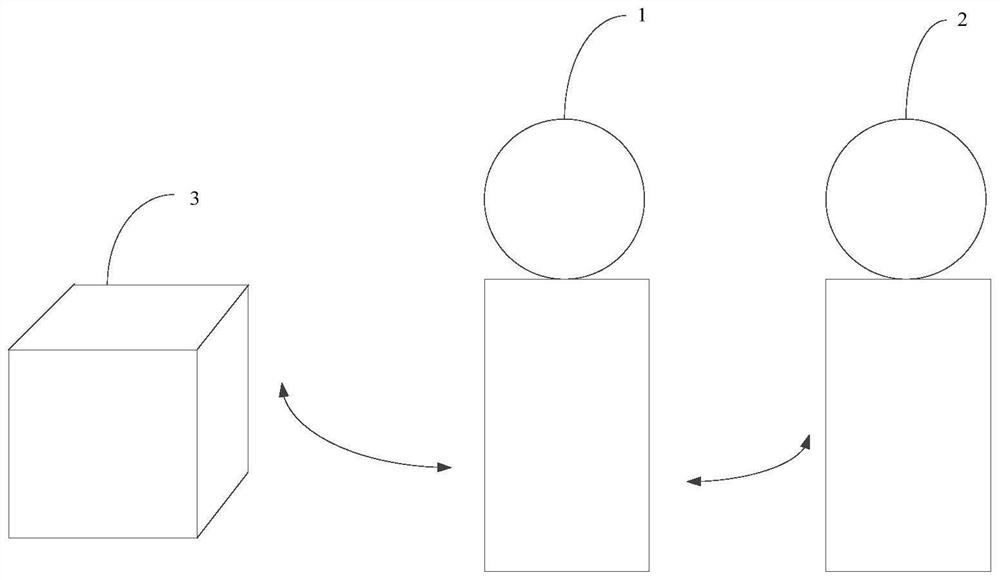

[0053] figure 1 A schematic diagram of an application scenario of the method for maintaining a robot system provided by an embodiment of the present invention is shown, and for ease of description, only parts related to this embodiment are shown.

[0054] see figure 1 , establish a communication connection between the normal robot 1 and the faulty robot 2, the established connection can be through the UART interface for communication, the output interface of the normal robot is connected with the input interface of the faulty robot, and the input interface of the normal robot is connected with the faulty robot output interface connection; the normal robot 1 sends a debugging command to the faulty robot 2 to obtain the debugging information of the faulty robot; the normal robot establishes a communication connection with the system maintenance terminal 3, and the communication connection can be a wired network or a wireless network, such as Internet, Wi-Fi or 5G, 4G, 3G, etc.;...

Embodiment 2

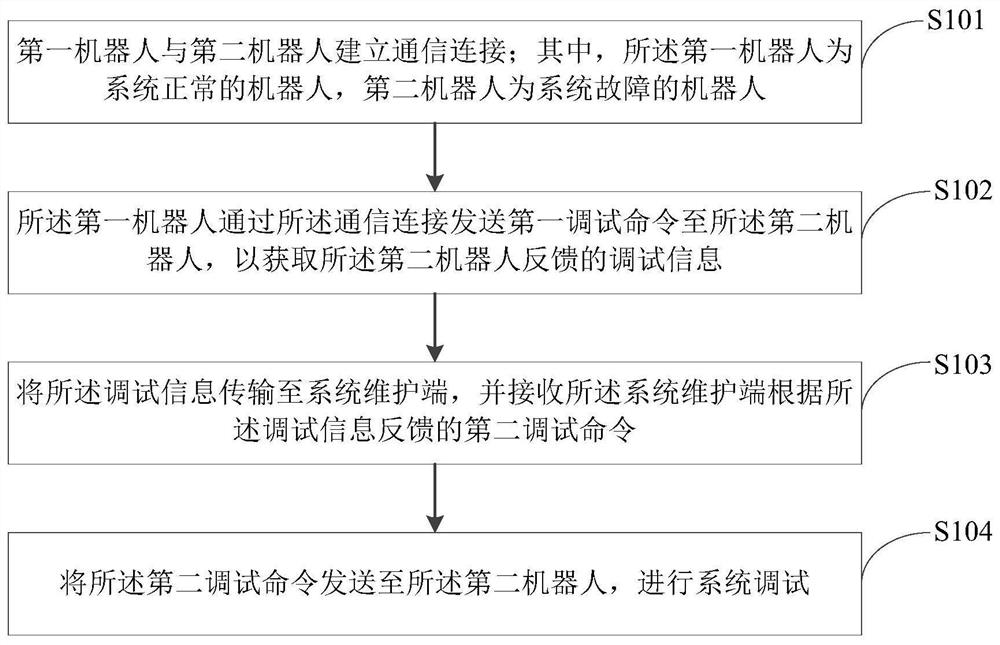

[0056] see figure 2 , is a schematic diagram of the implementation process of the robot system maintenance method provided by Embodiment 2 of the present invention. In this method, two or more robots are based on the UART communication interface of the robot main board to realize the fault analysis and maintenance of the faulty robot system , the subject of execution of this method is the first robot, that is, a robot with a normal system. The method may include the steps of:

[0057] Step S101, the first robot establishes a communication connection with the second robot; wherein, the first robot is a robot with a normal system, and the second robot is a robot with a system failure.

[0058] In this embodiment, the first robot is a robot with normal functions, and the second robot is a robot with a system failure; in an application site, there are at least two robots, among which there is at least one robot with normal functions, The other one or more can be malfunctioning ...

Embodiment 3

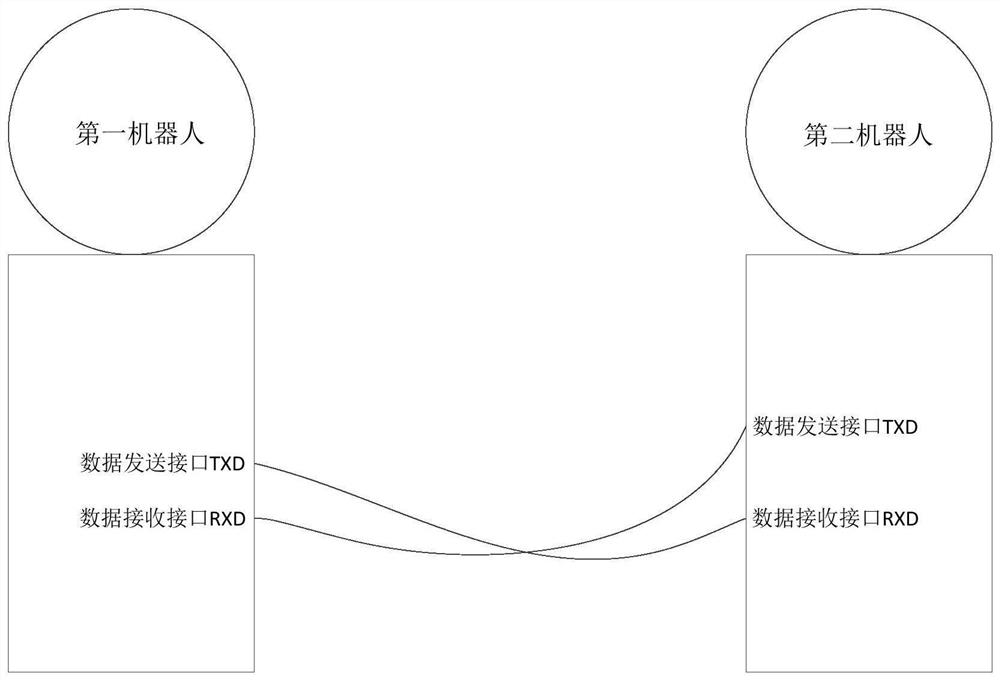

[0087] see Figure 4 , is a schematic diagram of the interaction process of the robot system maintenance method provided by the embodiment of the present invention, and those involved in the interaction process include figure 1 In the normal robot 1, the faulty robot 2, and the system maintenance terminal 3, the realization principle of the interaction process is the same as figure 2 The implementation principles described above are consistent, so only briefly describe the interaction process without repeating it:

[0088] 1. The normal robot establishes a communication connection with the faulty robot;

[0089] 2. The normal robot sends the first debugging command to the faulty robot;

[0090] 3. The faulty robot feeds back the debugging information to the normal robot according to the debugging command;

[0091] 4. The normal robot establishes a remote communication connection with the system maintenance terminal;

[0092]5. The normal robot sends the debugging informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com