D-shaped temporary beam erecting method for underneath pass railway frame bridge type tunnel

A frame bridge and convenient beam technology, applied in the field of road and bridge engineering, can solve problems such as the inability to meet the support piles of D-type convenient beams.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A D-shaped convenience beam overhead method passing under a railway frame bridge tunnel, comprising the following steps:

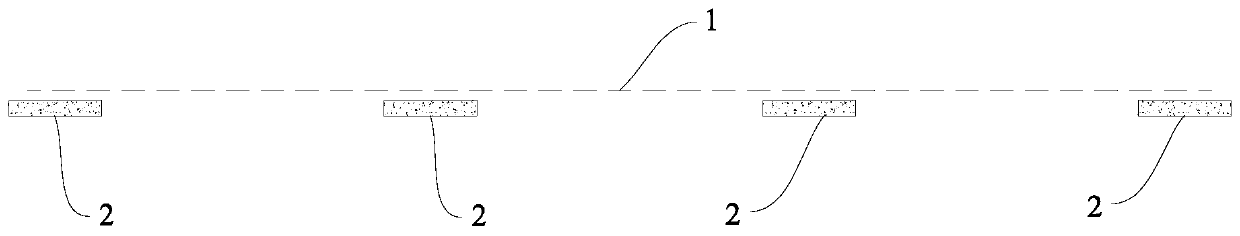

[0039] Step 1: If figure 1 As shown, utilize skylight time, on existing railway embankment (below track surface 1), construct open-cut foundation 2, as the fulcrum of temporary beam 3, wherein said open-cut foundation 2 is strip foundation;

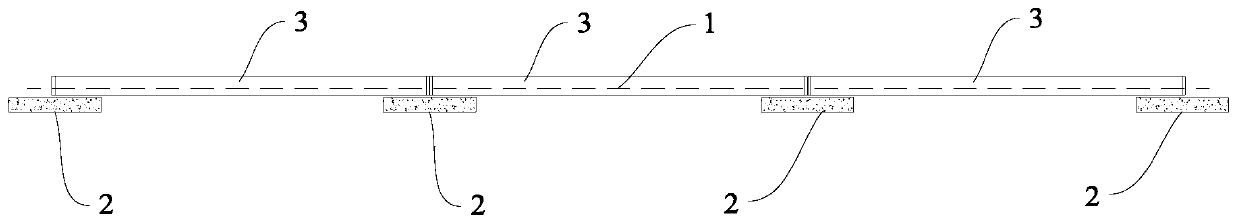

[0040] Step 2: If figure 2 As shown, using the skylight time, a temporary beam 3 is erected on the open excavation foundation 2 to reinforce the line, wherein the temporary beam 3 is a D-shaped beam or a rail beam;

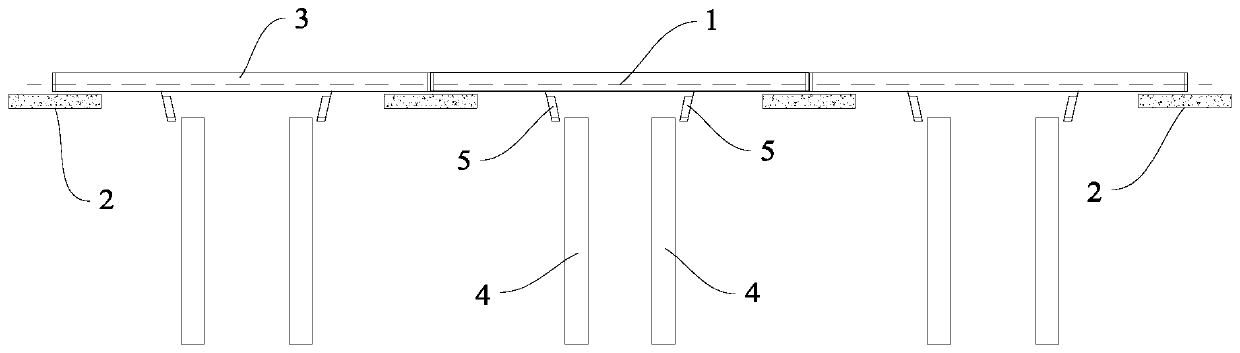

[0041] Step 3: If image 3 As shown, the excavated pile 4 is excavated on the roadbed after reinforcement, and the pile 4 is dug to 10m-15m below the road shoulder, and the pile 4 is poured, and a retaining pile is set at the end of the pile 4 Ballast Wall 5:

[0042] Step 4: If Figure 4 As shown, after the hole-digging piles 4 reach the design strength, the reinforced concrete lateral suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com