Curved-surface curtain wall connecting structure and construction method thereof

A technology for connecting structures and curtain walls, applied to walls, building components, building structures, etc., can solve problems such as uneven installation of curtain wall panels, achieve the effects of ensuring construction quality, satisfying aesthetics, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

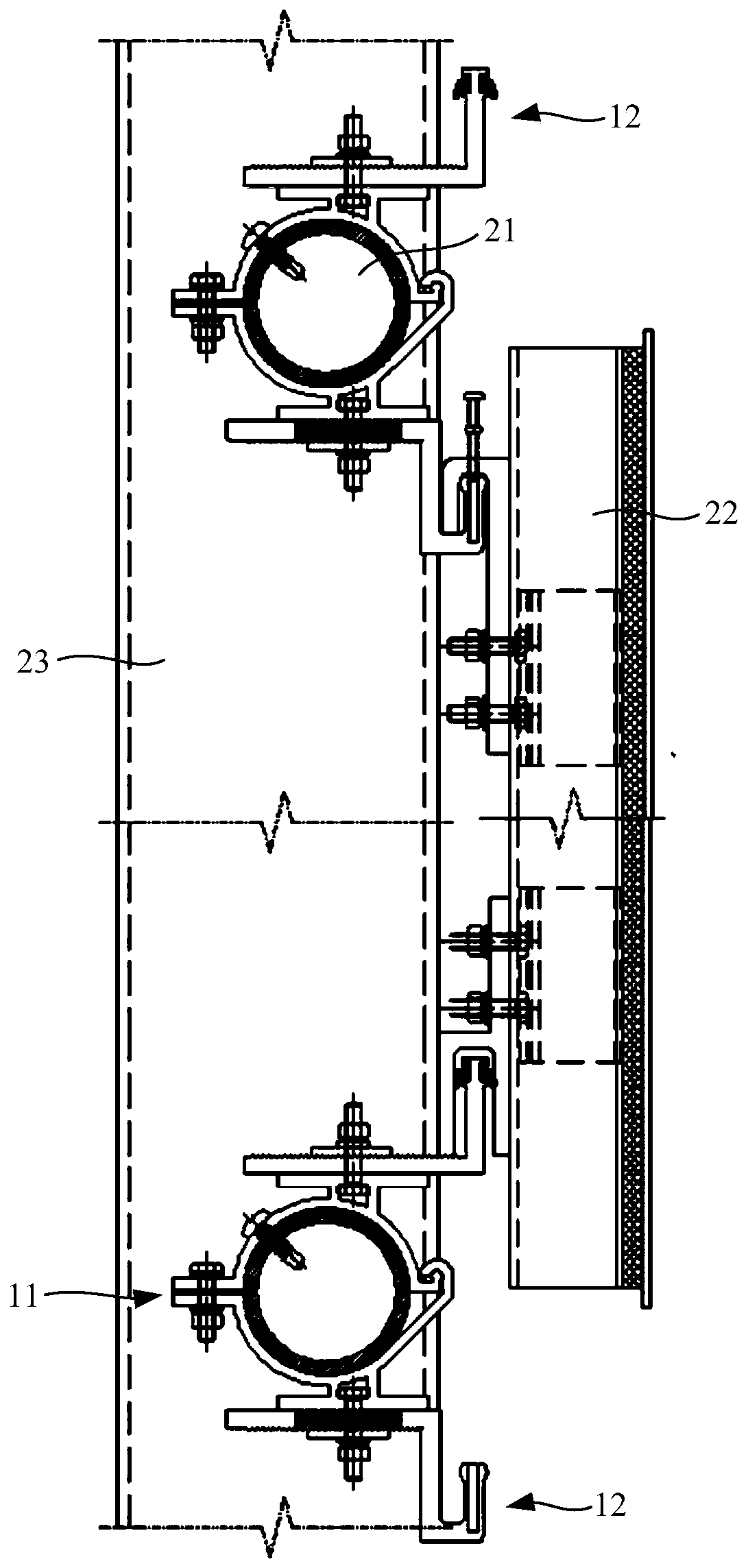

[0036] As a preferred embodiment of the present invention, the horizontal keel 21 is cylindrical;

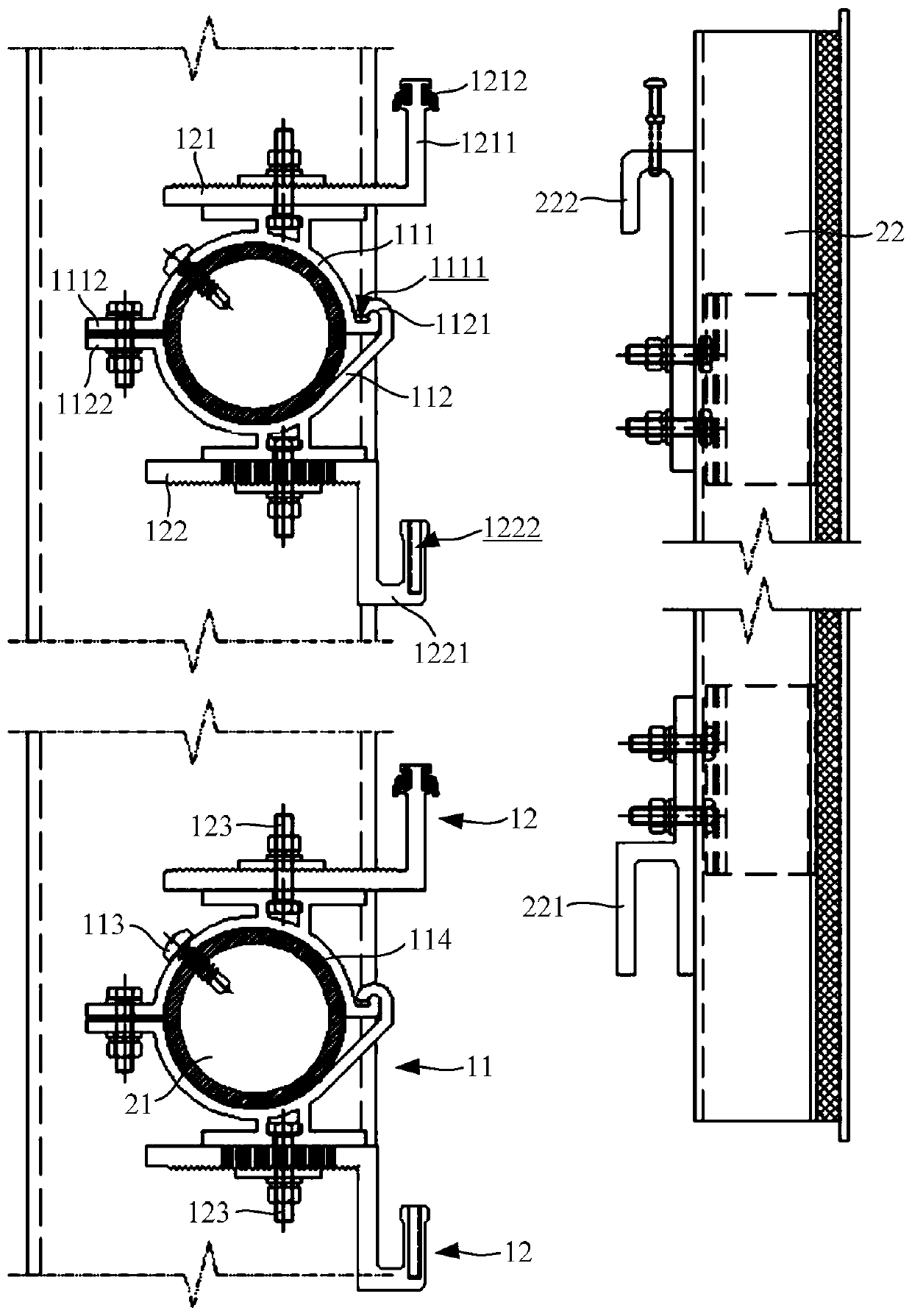

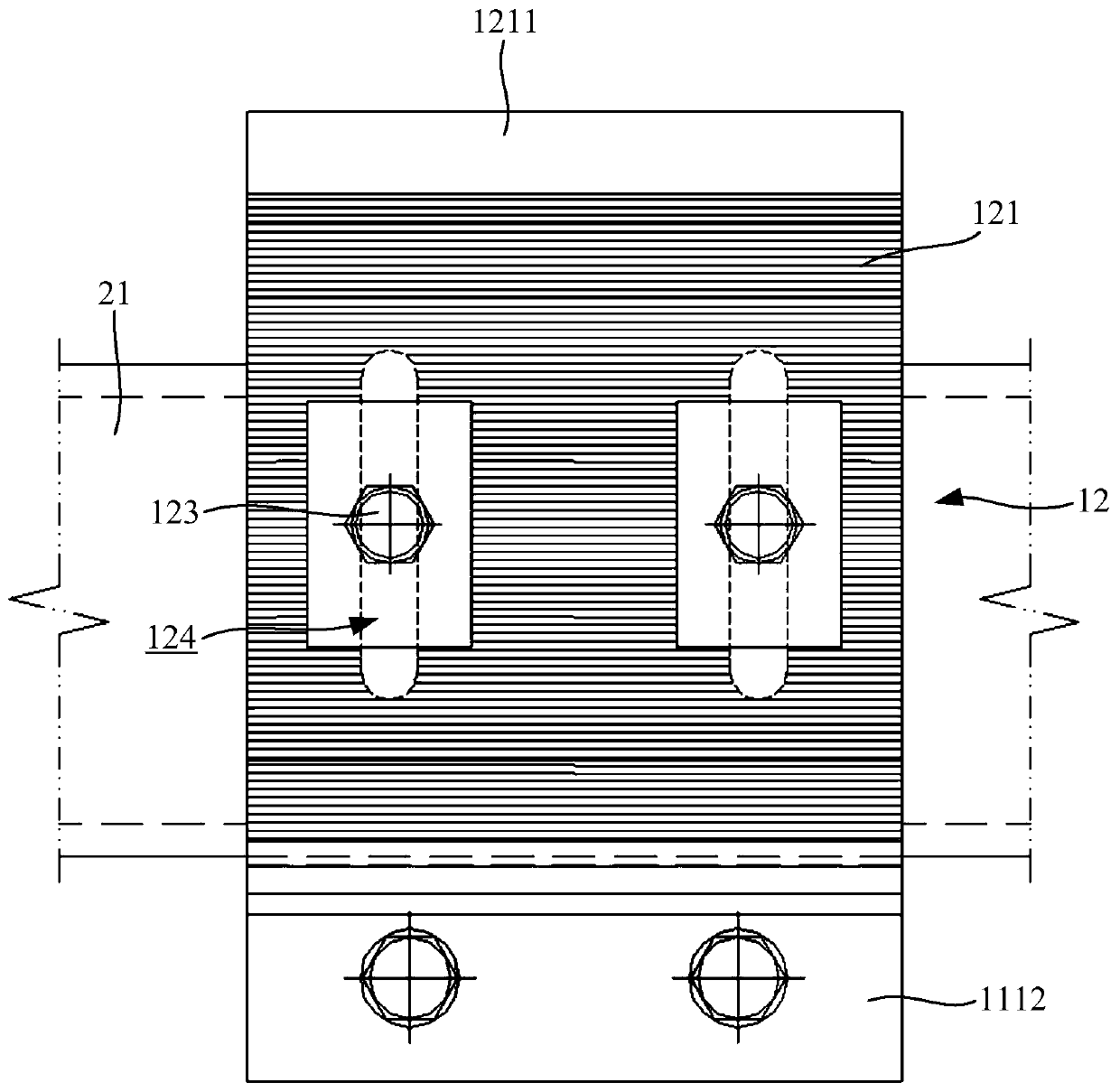

[0037] The fixing base 11 includes a first clamping piece 111 and a second clamping piece 112 that are butt-connected. After the first clamping piece 111 and the second clamping piece 112 are docked, a clamping space that matches the horizontal keel 21 is formed inside. , through the clamping space, the first clamping part 111 and the second clamping part 112 can be clamped on the horizontal keel 21, and the first clamping part 111 and the second clamping part 112 can be rotated and fixed around the horizontal keel 21 Seat 11.

[0038] Specifically, one end of the first clamping member 111 is bent to form a slot 1111 , and the other end is bent to form a first fixing portion 1112 ;

[0039] One end of the second clamping member 112 is formed with a hook 1121 matching the slot 1111 , and the other end is formed with a second fixing portion 1122 corresponding to the first fixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com