A self-anchored auxiliary clamping tool for butt jointing of the end of the stress tendon between the floor shear walls

A technology of clamping tools and shear walls, which is applied in the processing of building materials, construction, building construction, etc., can solve the problem of affecting the efficiency of butt joint stability and reinforcement operations of steel bar ends, the safety of construction operations, and the position of butt joints at steel bar ends Problems such as misalignment and inconvenient laying-out operation for floor construction achieve the effect of convenient operation of alignment connection reinforcement, compact fit, convenient installation, disassembly and reorganization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

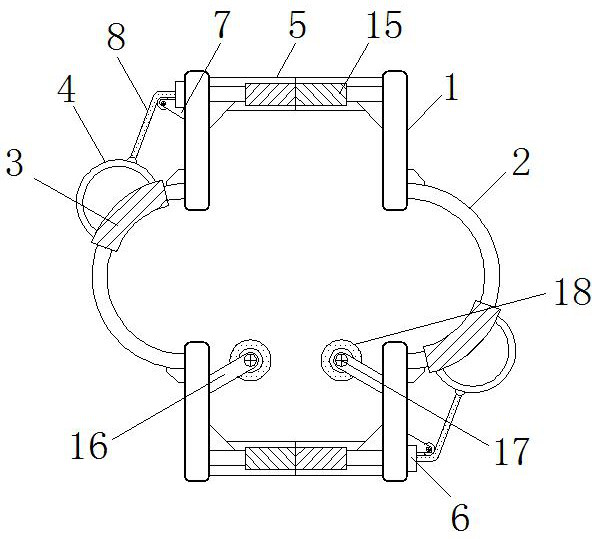

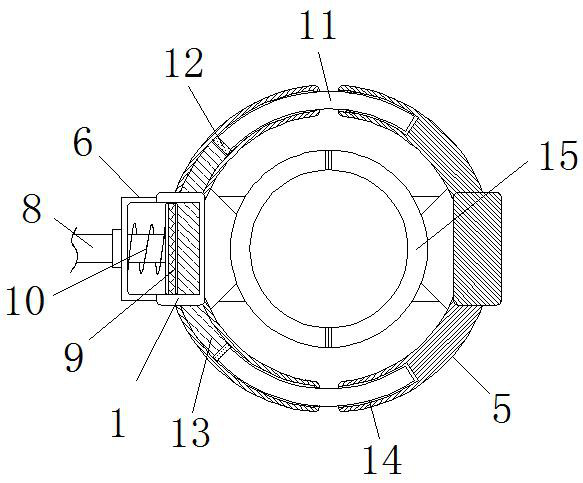

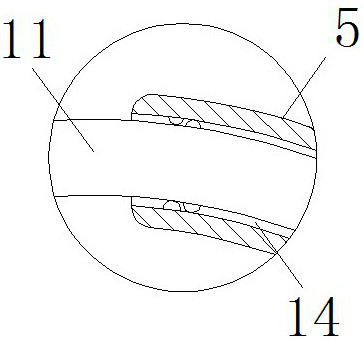

[0032] see Figure 1-5 , a self-anchored auxiliary clamping tool for docking the end of the stress tendon between the floor shear walls, including a vertical rod 1 and kerosene liquid 13, the middle part of the vertical rod 1 is fixedly installed with an arc rod 2, and the arc rod 2 The outer sleeve is provided with an installation sleeve 3, and the outer wall of the installation sleeve 3 is fixedly connected with a fixed ring 4, and a positioning ring 5 is fixedly installed between the ends of the vertical rod 1, and the outer wall of the positioning ring 5 on one side of the vertical rod 1 runs through A sealing cylinder 6 is fixed, and a guide wheel 7 is fixed on the outer wall of the positioning ring 5 below the sealing cylinder 6, and a connecting rope 8 is slidably installed on the outside of the guiding wheel 7, and the two ends of the connecting rope 8 are respectively connected to the outer wall of the fixing ring 4 and the inside of the sealing cylinder 6, and the ed...

Embodiment 2

[0037] see Figure 1-4 and Image 6 , a self-anchored auxiliary clamping tool for docking the end of the stress tendon between the floor shear walls, including a vertical rod 1 and kerosene liquid 13, the middle part of the vertical rod 1 is fixedly installed with an arc rod 2, and the arc rod 2 The outer sleeve is provided with an installation sleeve 3, and the outer wall of the installation sleeve 3 is fixedly connected with a fixed ring 4, and a positioning ring 5 is fixedly installed between the ends of the vertical rod 1, and the outer wall of the positioning ring 5 on one side of the vertical rod 1 runs through A sealing cylinder 6 is fixed, and a guide wheel 7 is fixed on the outer wall of the positioning ring 5 below the sealing cylinder 6, and a connecting rope 8 is slidably installed on the outside of the guiding wheel 7, and the two ends of the connecting rope 8 are respectively connected to the outer wall of the fixing ring 4 and the inside of the sealing cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com