Method for recycling waste alkali liquor generated by absorbing HCl and application of the method

A technology for waste lye and absorbing liquid, applied in chemical instruments and methods, alkali metal fluoride, preparation with chloride, etc., can solve the problems of increased cost, waste, environmental pollution, etc., and save the cost of waste disposal and production and operation. cost, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

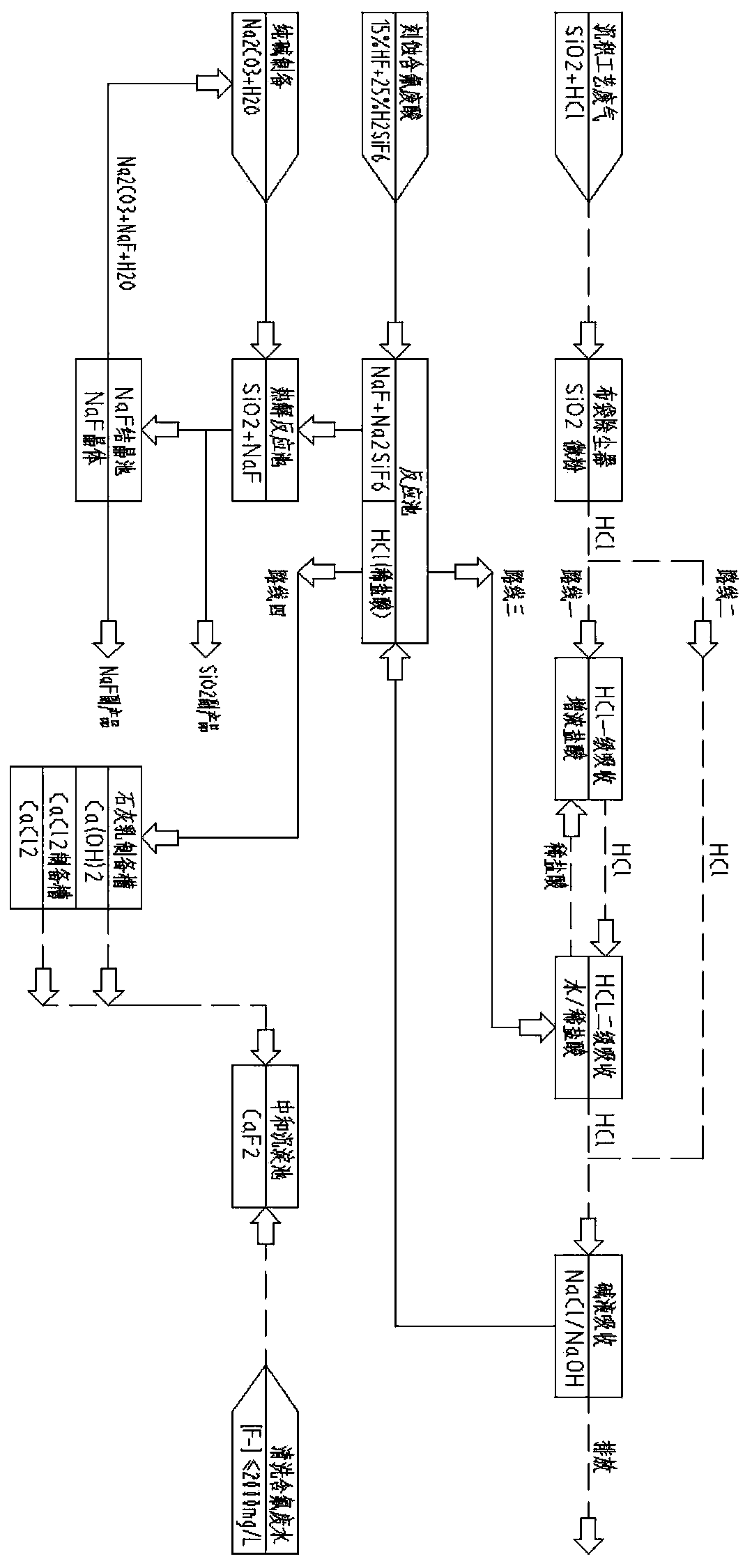

[0034] The present invention will be described in detail below in conjunction with the drawings.

[0035] The present invention provides a method for reusing waste lye produced by absorbing HCl. The method includes the following steps:

[0036] (1) Add the waste liquid produced by quartz etching treatment to the waste lye produced by absorbing HCl, HF, H 2 SiF 6 React with NaCl and NaOH to produce NaF and Na 2 SiF 6 And dilute hydrochloric acid;

[0037] (2) Combine the NaF and Na obtained in step (1) 2 SiF 6 Add excess Na 2 CO 3 In the solution, heat and stir well, Na 2 SiF 6 And Na 2 CO 3 Reaction to produce NaF, SiO 2 And CO 2 .

[0038] In the method for reusing the waste lye produced by absorbing HCl provided by the present invention, the effects of treating waste with waste and reusing waste are achieved. Firstly, after absorbing the HCl gas through the NaOH solution, a waste lye containing NaCl and NaOH is obtained. In order to avoid the discharge of a large amount of absorbed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap