A method of installation and disassembly of soil nail wall support

An installation method and soil nailing wall technology, applied in excavation, sheet pile wall, construction and other directions, can solve the problems of resource waste installation, slope deformation, damage, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0055] According to the installation and dismounting method of above-mentioned a kind of soil nailing wall support, a specific embodiment of the present invention is as follows:

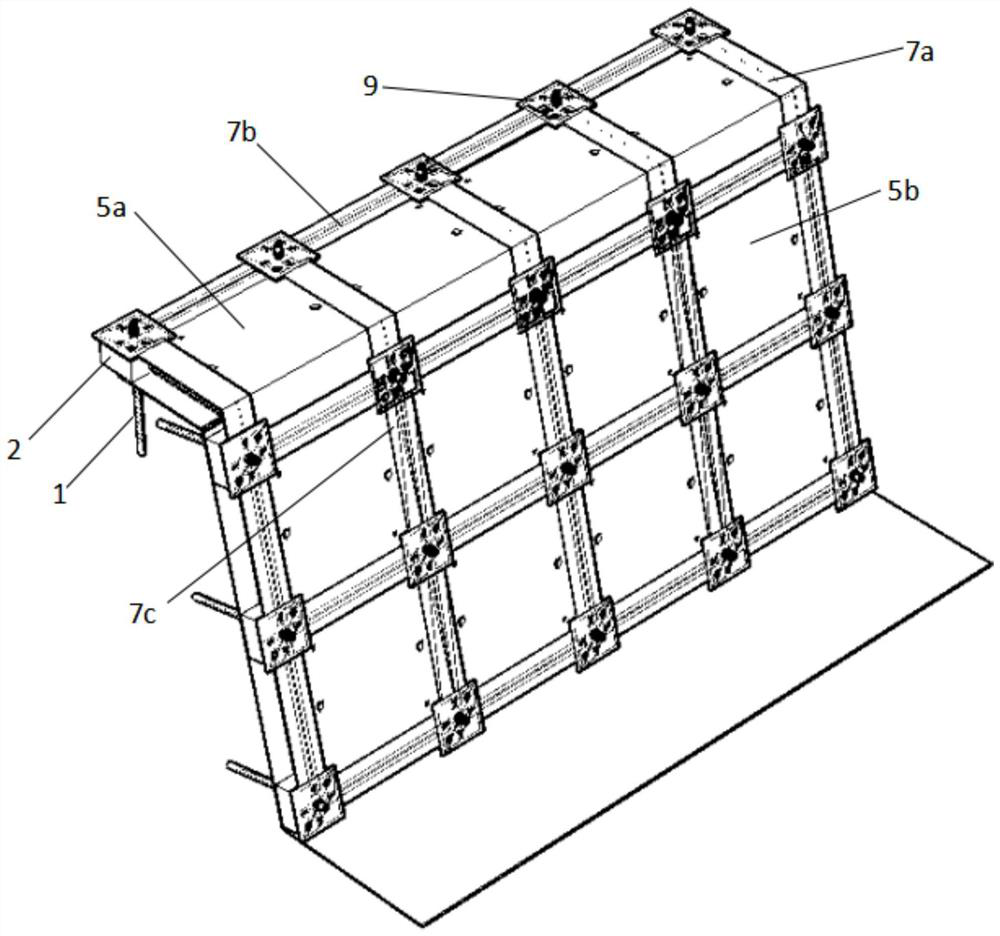

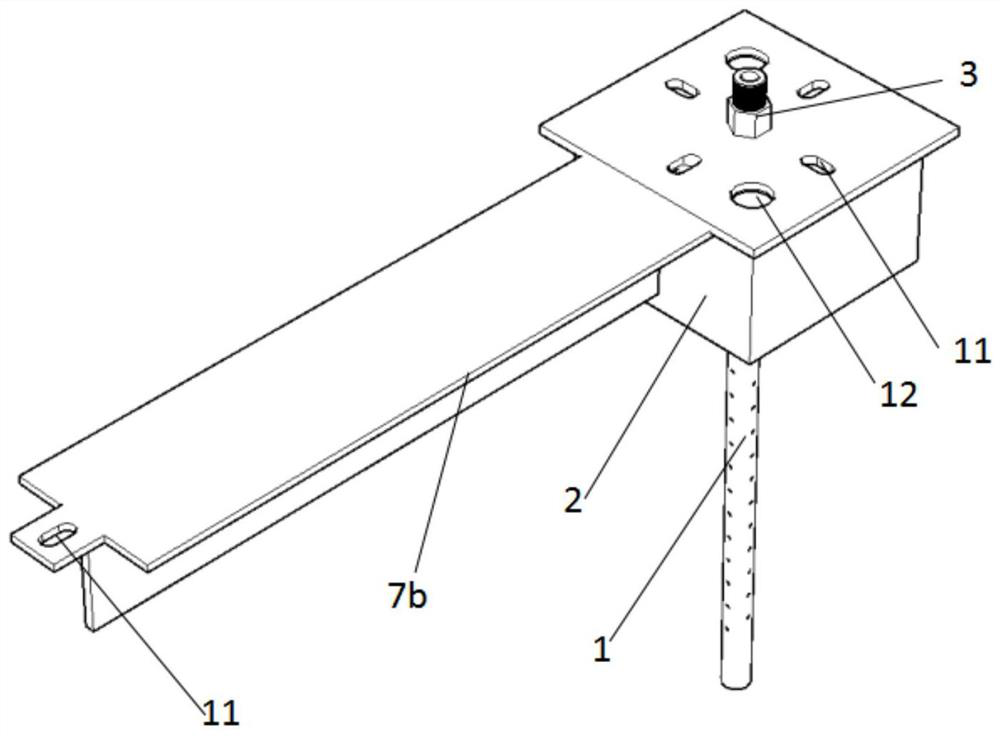

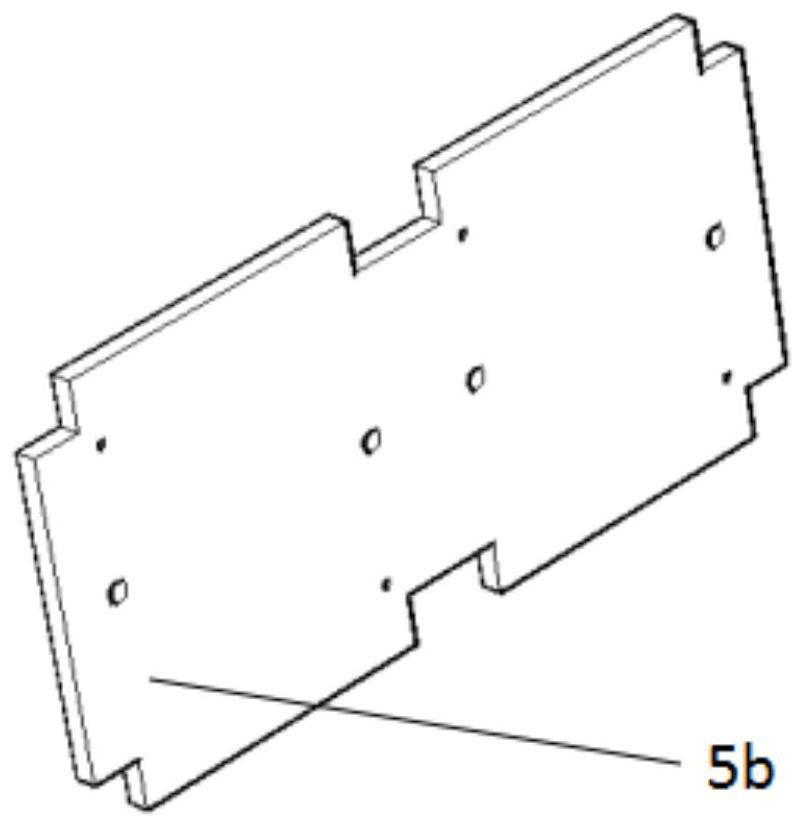

[0056] The invention relates to an assembly-type preloaded GFRP composite material soil nail wall support construction method. All components of the soil nail wall are standard parts and can be prefabricated in a factory, and the components only need to be assembled on site. Soil nail drilling is carried out on the pre-supported slope surface. Each row of longitudinal holes is required to be on a straight line, and each row of horizontal holes is required to be on the same line. Soil nails, and then sequentially assemble GFRP joints, GFRP nuts, air bags or air bags, GFRP panels, connecting rods and pressure plates. Among them, the function of the air bag or the air bag is to make the panel and the slope closely fit, preload by inflating, and bear the earth pressure. After the support is completed, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com