a motor

A shell and end cap technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of complicated assembly process of end caps and easy damage of end caps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

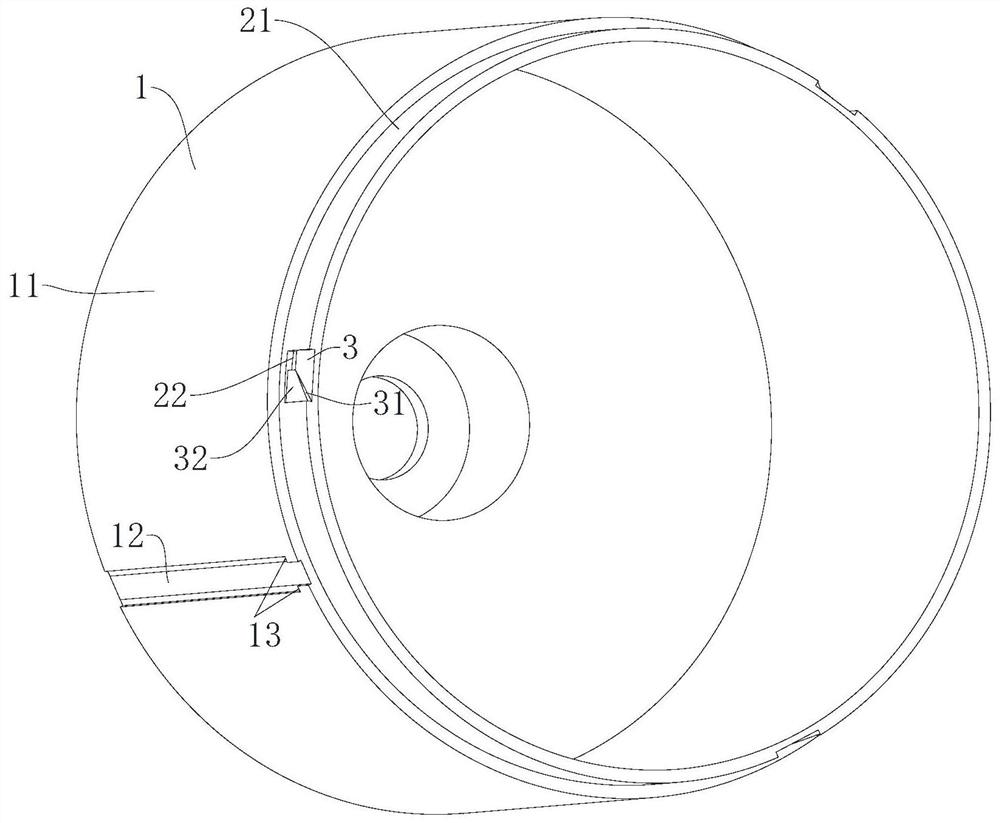

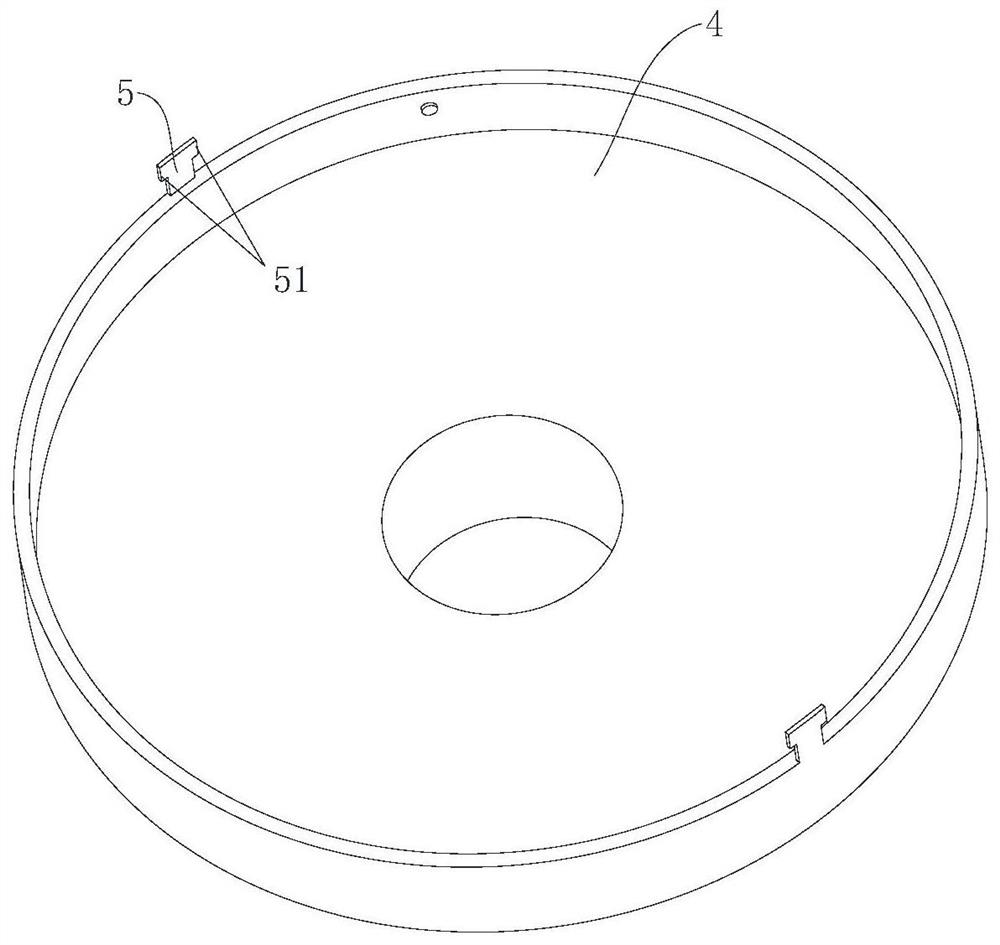

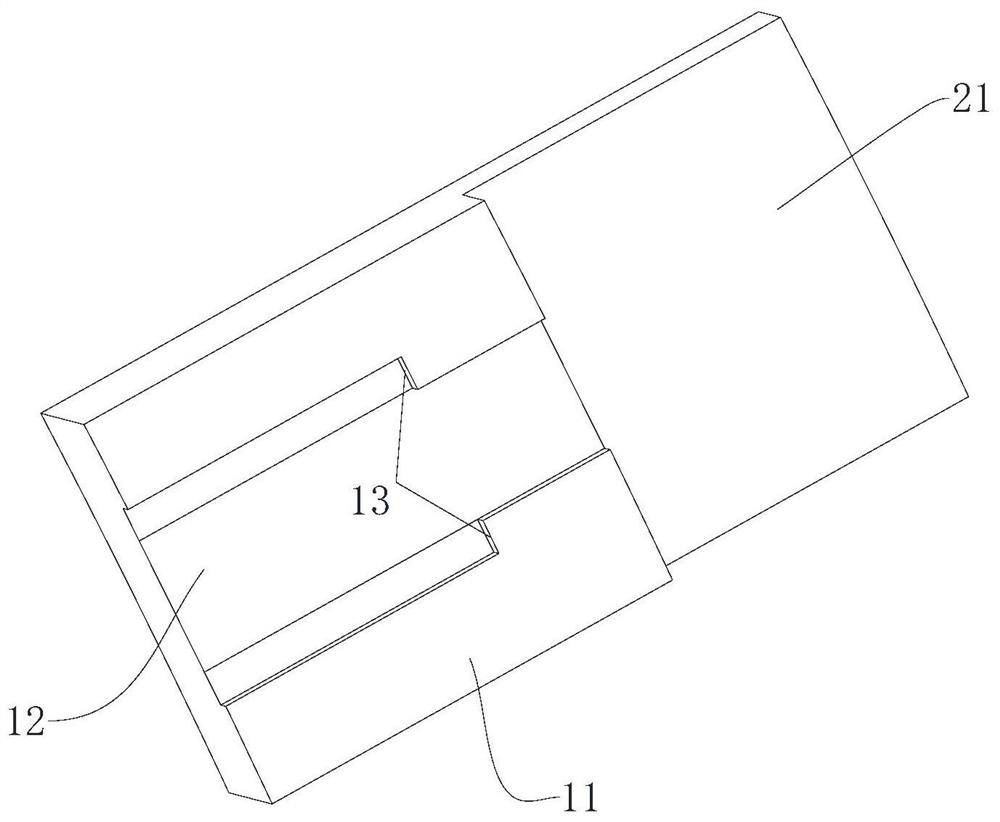

[0065] This embodiment provides a motor, such as figure 1 , figure 2 As shown, it includes: a housing 1, including a seam 2 and an end cap 4 for closing the seam 2; The first part and the second part, the first part and the second part interfere with each other, so that the first part and the second part are relatively stationary in a first direction, and the first direction is parallel to the direction of the housing 1 central axis, and the first direction is directed from the housing 1 to the end cover 4; the second fixing assembly includes the first split body and the The second split body, the first split body and the second split body interfere with each other, so that the first split body and the second split body are relatively stationary in a second direction, and the second direction is parallel to the The direction of rotation of the rotor inside the housing 1. During the working process of the motor, due to the continuous rotation of the internal rotor, the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com